- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure-control valves

Results for

Pressure-control valves - Import export

MÜLLER CO-AX GMBH

Germany

Within the family of pressureregulating valves, a technical distinction is made between series of bypass valves, inline valves and threeway valves.

Request for a quote

RIEGLER & CO.KG

Germany

Blocking valves control the opening and closing of piping systems. They control the inlet, flow or outlet of liquids and gases. Flow valves regulate the volume flow of the fluid used. We have throttle valves, throttle check valves, check valves and stopper valves. Furthermore we offer quick relief valves, toggle lever valves, compact pressure controllers and functional connectors. All mentioned blocking and flow valves are available in various sizes, materials, and pressure, flow and temperature ranges.

Request for a quote

RIEGLER & CO.KG

Germany

Blocking valves control the opening and closing of piping systems. They control the inlet, flow or outlet of liquids and gases. Flow valves regulate the volume flow of the fluid used. We have throttle valves, throttle check valves, check valves and stopper valves. Furthermore we offer quick relief valves, toggle lever valves, compact pressure controllers and functional connectors. All mentioned blocking and flow valves are available in various sizes, materials, and pressure, flow and temperature ranges.

Request for a quote

RIEGLER & CO.KG

Germany

Blocking valves control the opening and closing of piping systems. They control the inlet, flow or outlet of liquids and gases. Flow valves regulate the volume flow of the fluid used. We have throttle valves, throttle check valves, check valves and stopper valves. Furthermore we offer quick relief valves, toggle lever valves, compact pressure controllers and functional connectors. All mentioned blocking and flow valves are available in various sizes, materials, and pressure, flow and temperature ranges.

Request for a quote

RIEGLER & CO.KG

Germany

Blocking valves control the opening and closing of piping systems. They control the inlet, flow or outlet of liquids and gases. Flow valves regulate the volume flow of the fluid used. We have throttle valves, throttle check valves, check valves and stopper valves. Furthermore we offer quick relief valves, toggle lever valves, compact pressure controllers and functional connectors. All mentioned blocking and flow valves are available in various sizes, materials, and pressure, flow and temperature ranges.

Request for a quote

RIEGLER & CO.KG

Germany

Blocking valves control the opening and closing of piping systems. They control the inlet, flow or outlet of liquids and gases. Flow valves regulate the volume flow of the fluid used. We have throttle valves, throttle check valves, check valves and stopper valves. Furthermore we offer quick relief valves, toggle lever valves, compact pressure controllers and functional connectors. All mentioned blocking and flow valves are available in various sizes, materials, and pressure, flow and temperature ranges.

Request for a quote

RIEGLER & CO.KG

Germany

Blocking valves control the opening and closing of piping systems. They control the inlet, flow or outlet of liquids and gases. Flow valves regulate the volume flow of the fluid used. We have throttle valves, throttle check valves, check valves and stopper valves. Furthermore we offer quick relief valves, toggle lever valves, compact pressure controllers and functional connectors. All mentioned blocking and flow valves are available in various sizes, materials, and pressure, flow and temperature ranges.

Request for a quote

RIEGLER & CO.KG

Germany

Blocking valves control the opening and closing of piping systems. They control the inlet, flow or outlet of liquids and gases. Flow valves regulate the volume flow of the fluid used. We have throttle valves, throttle check valves, check valves and stopper valves. Furthermore we offer quick relief valves, toggle lever valves, compact pressure controllers and functional connectors. All mentioned blocking and flow valves are available in various sizes, materials, and pressure, flow and temperature ranges.

Request for a quote

RIEGLER & CO.KG

Germany

Blocking valves control the opening and closing of piping systems. They control the inlet, flow or outlet of liquids and gases. Flow valves regulate the volume flow of the fluid used. We have throttle valves, throttle check valves, check valves and stopper valves. Furthermore we offer quick relief valves, toggle lever valves, compact pressure controllers and functional connectors. All mentioned blocking and flow valves are available in various sizes, materials, and pressure, flow and temperature ranges.

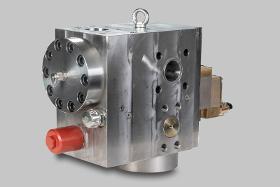

Request for a quoteSTÄHLE GMBH

Germany

High precision vacuum pressure control valve for exhaust emission analyzer. Temperature proof up to 180 °C and acid resistant against exhaust of combustion engines. Constant vacuum pressure even at high pressure peaks at inlet (for example generated by turbo combustion engines) Outlet pressure: 0.9 at (0.1 bar below atmosphere) Outlet pressure deviation: approx. 70 mbar Inlet pressure: max. 3 bar (4 at) Different outlet pressure ranges and other flange versions can be offered.

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-L 3 / 18 barrel emptying system offers a modern way of emptying containers.The connection with the ViscoTec VMP dispenser series for the removal of the medium offers the following advantages: - container sizes from approx. 50 l to 300 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - removal of materials loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: Removal of materials directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XS hobbock emptying system offers a modern way of emptying containers.The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from approx. 5 l to 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers - direct dosing as pulsation-free flow rate

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XL drum emptying system offers a modern way of emptying containers. The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - Bridge frame can be driven underneath with drums on pallets - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoTreat-R preparation and feeding system ensures an even and reliable product supply. At the same time, the medium is optimally prepared for the production process by stirring and circulating. The use of the VRP dispenser series for the further transport of the medium offers the following advantages: optimal processing of viscosities up to 50,000 mPas very low shear stress of the medium very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - no air supply necessary - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - Stator material is adapted to the medium to be pumped Application: - Feeding and processing of medium to highly sensitive media, e.g.: Silicones, adhesives, resins, greases, colour pastes, metal-filled pastes

Request for a quote

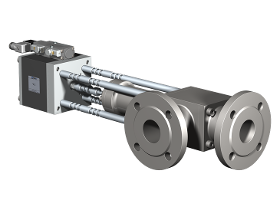

KAMAT GMBH & CO. KG

Germany

Our valves are manufactured in-house and matched to the characteristics and pressures of your application. Our valves are full lift safety valves and can be spring loaded or pilot operated. All our valves are supplied set to your required working pressure up to a maximum of 4,000 bar and flow rates up to 4,700 l/min. Two versions of spring-loaded safety valves, even ATEX compliant The simpler high pressure valves have a rotatable bypass connection to dispose of leaking fluid. Pilot operated valves require a block flange. Like all other KAMAT products, these are ATEX compliant and can be manufactured in special materials to suit the medium being pumped.

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT unloading valves are the ideal solution for precise pressure control at fixed or varying volumes. A fast and smooth acting high pressure valve that redirects the flow of the conveyed medium when the desired pressure is reached on the discharge side. Smooth operation makes it a reliable partner for pressure testing pipelines and vessels in all conditions. Reliability is further enhanced by the addition of a surge valve, which is further protected by its own filter. This extra filter is important when solid particles are present in the fluid, such as when drilling mud is reinjected into a well. As well as being reliable, our valves are simple and versatile to control. They can be controlled mechanically, pneumatically, electrically or hydraulically, all with the option of remote control. Special materials can also be used to provide an ideal solution for the process industry.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Analogue flow indicators for measuring the flow rate of fluids in mobile and industrial hydraulics. The SDMKR is designed with a loading valve for the strain test of the hydraulic system to facilitate precise control of the operating pressure. In addition, this product can also be subjected to a reverse flow direction (without flow rate determination). ▪ Suitable for Mineral Oil (Aluminium), HFC Fluids and Water (Brass) ▪ Designed for in-line installation ▪ Mechanical flow measurement ▪ Controlling working pressure with a pressure control valve (only SDMKR) ▪ Flow indication in l/min and GPM for Aluminium units, Brass units have flow indication for Water and Oil both in l/min ▪ Aluminium unit: Dual scale ▪ Brass unit: Single scale ▪ Thread to connect with pressure gauge (only SDM) Accuracy (at a kinematic viscosity of 28cSt): ▪ Flow: ±4 % FSD ▪ Temperature: ±2,5 °C / ±5 °F ▪ Pressure (only SDMKR): ±1.6 % FS* ▪ Temp. measuring range: +20 °C ... +110 °C / +55 °F ... +245 °F ▪...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

The injector-glass-blasting cabin is operated by hand with a gun. A blast-collecting collector ensures a smooth blasting circuit within the system. With the help of roller rails, as well as through-slots (on the side and in the roof surface with special brushes against the penetration of dust), surface treatment of glass panes is easy. On the front side there is an easy-open loading door for radiating hollow glass bodies. A work grate and two shock-proof long-field lamps (for glare-free illumination of the blasting chamber) guarantee a smooth workflow. The foot switch as well as the drain cup on the blasting agent funnel, an attached control box with pressure reducing valve and pressure gauge, motor protection switch, on / off button, solenoid valve, control lights, switches for interior lighting, main switch, emergency stop switch and support control ensure uncomplicated operation.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hightemperature sliding gate control valve type 8024 in reinforced GS3 design with integrated positioner is suitable for a wide range of process applications up to 530°C. Media such as steam, liquids, gases, etc. can be precisely controlled even in the hightemperature range. Digital positioner type 8049 Pneumatic and electropneumatic positioner type 8047 Positioner with integrated process controller type 8049 IPC Positioner type 8047 and type 8049 also in explosionproof version Positioner with mounting acc. to NAMUR standard Metal bellows Limit switch Position feedback Manual override Pilot valve . . .

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The pneumatic sliding gate control valve type 8028 in reinforced GS3 design with integrated positioner and with an 80 mm diaphragm actuator is ideal for compact plant installations in process technology. In addition to the compact design, this valve is characterised by high control precision and a long service life. Digital positioner type 8049 Positioner type 8049 in explosionproof version Positioner with integrated process controller type 8049 IPC Metal bellows Limit switch Position feedback Pilot valve . . .

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Brake force control valve for stepless regulation of the brake pressure.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hygienic angle seat control valve type 7025 with integrated digital positioner is specially adapted for use in the food and beverages production. Suitable for controlling product streams, drinking water, CO2, nitrogen as well as sterile steam and sterile air. All wetted plastics are FDA-compliant and conform to EC Regulation 1935/2004 and the EU Plastics Regulation 10/2011. The hygienic angle seat valve is also certified to Technical Instructions on Air Quality Control (TA-Luft) in accordance to ISO 15848-1 and on request can be supplied with an acceptance test certificate in accordance with EN10204 3.1.

Request for a quote

MÜLLER CO-AX GMBH

Germany

This type is a pneumatically actuated valve with 2 port connections and 2 switching positions. The V2 has been developed for hot gases up to 400°C.

Request for a quote

EM-TECHNIK GMBH

Germany

The 5D pressure reducing valve is used to reduce system pressures to largely constant working pressures. Due to its design it requires extremely low maintenance in applications and is therefore suitable for horizontal and vertical installation.

Request for a quote

EM-TECHNIK GMBH

Germany

Series 5D pressure keeping valves are used to eliminate overpressures due to operation or due to the system. It eliminates pressure peaks by relieving the system if the set pressure is exceeded. Both versions of the pressure keeping valve can be installed horizontally or vertically in any installation position, allowing for versatile use.

Request for a quote

MÜLLER CO-AX GMBH

Germany

This series comprises valves with two connections that are operated by an electric motor. They are characterized by the fact that the valve stroke can be adjusted steplessly and held in place by a motor using a setpoint signal (420 mA or 010 V). This makes this series particularly suitable for precise dosing applications, as the servo motor reliably processes setpoint deviations of 1%.

Request for a quote

EISELE GMBH

Germany

- Whitworth pipe thread - Thread G2 for manual override - Chambered O-ring - Sealing: NBR - Material: brass nickel plated, Al black anodized - Allowable medium: air - Temperature range 14 to 158 °F (-10 to +70 °C) - Working pressure range 14,5 to 145 psi (1 to 10 bar) - Nominal flow rate measured when throttle is open at 87 psi (6 bar) and 14,5 psi (1 bar) pressure drop between inlet and exhaust

Request for a quote

EM-TECHNIK GMBH

Germany

The electrical fine control valve makes it possible to adjust volume flows precisely via an input signal (4-20 mA) and to approach an exact spindle position. The valve can also be controlled by a 24V continuous voltage. Position feedback is implemented by a 4-20 mA output signal. With an additional adapter, the valve can also be connected via an RS-232 interface to a computer. The valves are available in 1/4" (10-200 l/h of water) and 1/2" (50-500 l/h of water).

Request for a quoteResults for

Pressure-control valves - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Pneumatic systems and tools (8)

- Valves for industrial fittings (4)

- Dosing pumps (4)

- Plastics - industrial machinery and equipment (3)

- Valves for pneumatic equipment (3)

- Industrial valves, operating equipment (2)

- Hydraulic equipment (1)

- Dosing - machines and equipment (1)

- Sandblasting equipment (1)

- Valves, hydraulic (1)