- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- straighteners

Results for

Straighteners - Import export

GSW SCHWABE AG

Germany

High quality, extremely simple operation, unreached price/performance ratio For decades, the GSW Straighteners are valued all over the world. The Straightener with clamshell head (the GSW “AlligatorHead”) came out in 1968 – the RMA series – and today is being built in up to 2000mm width. This machine levels coil set and equals out tension with up to 12mm thick materials. It has given GSW a pioneer’s position in the industry. The RMZ series Straighteners convince where high straightening and pull forces are needed. Its frametype head design provides a high stiffness and elevates this technology to work with high demands in straightening quality – even with highertensile materials.

Request for a quote

GSW SCHWABE AG

Germany

To serve coil stock thicknesses of up to 15 mm Large diameter entry pinch rollers for smooth and lowwear strip transport Synchronized drive of all bottom work rollers and both entry pinch rollers Rollers are kept perfectly parallel with their penetration shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Enormous potential for performance and straightening quality through absolutely warpresistant head construction; supported by optional backup rollers and allroll drive system Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening as "cleaning stroke" Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Jobmemory for mot. straightening roller adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

GSW SCHWABE AG

Germany

Most simple threading Short setup as roller adjustment can be maintained with coilchanges Most comfortable maintenance and cleaning Synchronized drive of all bottom work rollers and both pinch rollers Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Jobmemory for mot. straightening roller adjustment Central edge guide adjustment via handwheel All roll drive Movable base Manual or hydraulic loop bridge... etc.

Request for a quote

GSW SCHWABE AG

Germany

GSW FeederStraighteners, series VRMA are just as simply operated as our Straighteners of the RMA series. With servo drive and length measuring system they offer the additional functionality of material feeding (positioning) over just straightening. Their most common application is cuttolength and spacesaving coil feeding. The already revolutionary alligatorhead can be extended with hydraulic opening for full piloting when feeding into stamping presses with progressive dies. For especially heavygauge materials or high demands in flatness, our VRMZ series FeederStraighteners are the correct answer. They process crosssections as large as 2000 x 5,0 mm. up to 2000 mm material width and 16 mm thickness max crosssection approx.. 2000 x 5 mm or 650 x 10 mm max net output approx. 50 – 150 m/min max cycles with piloting approx.. 40 – 100 SPM

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable to feed highspeed stamping presses Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

GSW SCHWABE AG

Germany

When straightening becomes core competence and strip or parts need to be completely removed of their tension, GSW Precision Straighteners are the answer of choice. They handle up to 2000mm wide and up to 6mm thick materials in strip or plate. Highest stiffness, closest centerdistances and the active driving of all rolls allow for perfect flatness results. Our newest development – the HighPerformance Straighteners, series RMB – answer questions raised thru current material development leading to increasing material strength, lessening thicknesses or the use of sandwich materials Their enormous stiffness, large pinch rolls and closest center distances evenly deliver highest straightening forces. If material surface quality must be fully preserved, the 6high design option is the right choice. Here, intermittent rolls prevent marking caused by the backup rolls and allow for a perfectly clean strip or plate.

Request for a quote

GSW SCHWABE AG

Germany

Both straightening and (servo) feeding performed in one operation Saves floor space as 2nd loop between standalone straightener and servo feed is eliminated Great feeding accuracy of +/ 0,1 mm Operator interface provides simple insertion or recall of feeding paramenters or memorized programs Synchronized drive of all bottom work rollers and both feed rollers Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening Hydraulic full piloting Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Motorized central height adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

GSW SCHWABE AG

Germany

Both straightening and (servo) feeding performed in one operation Saves floor space as 2nd loop between standalone straightener and servo feed is eliminated Large entry pinch rollers driven synchronously with all bottom work rollers Great feeding accuracy of +/ 0,1 mm Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Operator interface provides simple insertion or recall of feeding paramenters or memorized programs Hard chromed rollers Polyurethane coated rollers Hydraulic cleaning stroke Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Motorized central height adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

FÖHRENBACH GMBH

Germany

The straightening machine RM-1000 was developed for straightening deep-hole drills, as 4- and 6-axis version. The radial run-out of a drill is straightened using the 4-axis version. The 6-axis machine additionally corrects the camber of the shank and the head run-out of the soldered carbide drill bits. The maximum length of the drills is 1,000mm, the accuracy of the straightening process is 0.08 mm (depending on the work piece). An exportable straightening protocol is created for each straightening process. A robot cell is available as an option. Using this robot cell, the insertion and removal of the drills is performed. The robot cell is mobile and can be disconnected at any time in order to allow manual straightening processes.

Request for a quote

GSW SCHWABE AG

Germany

for wire ø 0,4 15 mm according to the required straightening quality, available with 5 to 13 rollers straightening rollers with precisionguiding also available as a set with 2 straightening units and angular fixations for horizontal and vertical straightening on request special perforations of the straightening rollers for noncircular material crosssection

Request for a quote

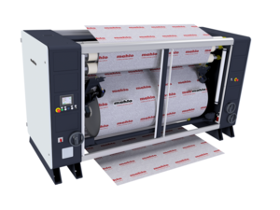

MAHLO GMBH & CO. KG

Germany

Removing irregular distortions Asymmetrical distortions (wavy, S-shaped, etc.) in textiles have always represented a huge challenge in the textile industry. A special straightening approach is needed particularly when the straightening process does not take place in combination with a stenter (e.g. before decatizers, digital printing systems, etc.). To restore the warp and weft threads to their original state, the Orthofact RMB generates a defined lateral tension using freewheeling, inclined pin wheels. This cross-tension stretches the warp threads. The resultant force controls the freewheeling pin wheels, since the weft threads will always seek out the shortest path from selvedge to selvedge. Distortion, no matter whether wavy or S-shaped, will be corrected.

Request for a quote

GSW SCHWABE AG

Germany

No coil expansion needed Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 21 individually adjustable straightening rollers to serve any almost demand on the quality of the straightening result Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers Clockspring guard Allroll drive for straightening rollers Hydraulic hold down arm (optional w powered endwheel) Hydraulic threading system with snubber and peeler (optional w powered snubber wheel) Motorized coil guides Motorized straightening rollers Hydraulic opening / closing of straightening head Hard chromed rollers Edge guides adjustable to center via handwheel (optional motorized) Jobmemory feature for all motorized functions... etc

Request for a quote

GSW SCHWABE AG

Germany

Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 13 individually adjustable straightening rollers to serve almost any demand on the quality of the straightening result Clockspring guard Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers

Request for a quote

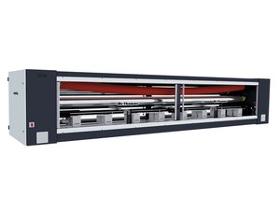

MAHLO GMBH & CO. KG

Germany

When the going gets rough ... The Orthopac CRVMC is especially designed for high mechanical load. Thanks to reinforced components, it is ideal for processing very heavyweight and wide materials. The arc of contact of the straightening rollers thereby depends on the desired straightening effect. With products without skews and bows, the straightening rollers are not enveloped unnecessarily. When the straightening rollers engage with the product, the uniform contact of the straightening rollers with the product is ensured over the entire width. This becomes possible through our innovative and unique roller positioning drive.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Heavy-duty weft straightening The heavy duty version. High demands due to large product widths (e.g. carpet) or dimensionally stable textiles with defined skew settings (e.g. denim) require a more solid configuration. The frame, bearings and rollers are designed for high loads. Available with up to 5400 mm working width.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Fine-tune straightening for heavyweight fabrics The special strength of the Orthopac GMFRC is the extremely high straightening accuracy at relatively small distortions. Thanks to reinforced components, it is ideal for processing really wide, heavyweight materials such as denim. The compact straightening unit is equipped with a skew and bow roller as standard. This arrangement allows for very fine adjustment of the straightening effect while permitting small device dimensions.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Fine-tune straightening of residual distortion This model represents a compact fine-straightening system for the correction of residual distortions. The special strength of the Orthopac MFRC is the extremely high straightening accuracy at relatively small distortions. The compact straightening unit is equipped with a skew and bow roller as standard. This arrangement allows for very fine adjustment of the straightening effect while permitting small device dimensions. Available with hydraulic or electrical straightening roller adjustment.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GSW SCHWABE AG

Germany

Slit metal often has camber. GSW builds Camber Straighteners, that help remove this defect. Coil Feed Lines that process small crosssections often only need minor straightening efforts. Here, we can help with pullthrough Straighteners also known as Flatteners. We usually mount them at the entrance of our Servo Roll Feeds or Air Feeds. Wire materials also often have a coil set – sometimes in two levels even. Single and dual Wire Straighteners help making such bent wires straight again.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Removing all types of distortions The fusion of pin wheel and roller straightening technology perfectly combines the advantages of both technologies and provides amazing straightening results. It provides reliable, quick distortion correction also for asymmetric web distortion. An infinitely variable unclipping roller minimises residual bow and edge distortions. The intelligent drive station with special voltage control for smallest product distortion activates or deactivates automatically (e.g. in case of blockages). A bypass function is available at the push of a button for products that cannot be straightened with the pin wheel.

Request for a quote

GSW SCHWABE AG

Germany

direct mounting to our Gripper Feeds, series ZVTMB or similar products with mounting bracket very costeffective flattening of the coil set best results through adjustment of both top straightening rolls rolls made of special steel and hardened and ground

Request for a quote

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

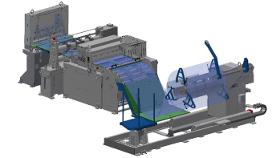

GSW SCHWABE AG

Germany

The Combination Slitting & Cut-To-Length Lines are probably the most flexible coil processing lines within the field of cutting. By combining the cutting lengthwise and across, the coil material can be processed into a variety of blanks. So, if your production features a limited number of different coils as basic materials, while the variety of widths and lengths of the blanks is high, a Combination Slitting & Cut-To-Length Line will be the right choice. The system bases on the Cut-To-Length technology while offering the additional functionality of slitting. Since the slitting technology is home-made too, we can provide a fully integrated solution. An incisive experience so to speak. As a sizable advantage, storage space and material costs per ton are both significantly reduced, and with Combination Slitting & Cut-To-Length Lines even smallest batches can be delivered immediately.

Request for a quote

GSW SCHWABE AG

Germany

Safe upending (90°) and rotating (180°) of coils Body design in solid welding construction with reinforced base with no pit or floor anchoring needed Body made of strong steel plates Base with large integrated floor plate and attached box construction to protect drive components Tilting unit with neatly welded half shell attachments and two reinforced coil tables welded at 90 degrees to provide safe material seating Bedding via four pressureresistant and fully enclosed bearings with lifetime lubrication Tilting shaft of highquality ductile steel with fully enclosed bearings Tilting drive via threephase motor and triplex type highstrength chain Rotating drive via welded surfacehardened sprocket, integrated in base Tilting function via initiator with arbitrary adjustable tilting point Electrical conrol in switch box with leftright selector switches and estop

Request for a quote

GSW SCHWABE AG

Germany

Safe upending of coils (90°) Body design in solid welding construction with reinforced base with no pit or floor anchoring needed Body made of strong steel plates Base with large integrated floor plate and attached box construction to protect drive components Tilting unit with neatly welded half shell attachments and two reinforced coil tables welded at 90 degrees to provide safe material seating Bedding via four pressureresistant and fully enclosed bearings with lifetime lubrication Tilting shaft of highquality ductile steel with fully enclosed bearings Tilting drive via threephase motor and triplex type Highstrength chain Tilting function via initiator with arbitrary adjustable tilting point Electrical conrol in switch box with leftright selector switches and estop

Request for a quote

GSW SCHWABE AG

Germany

Upenders are designed to safely tilt big and heavy coils – either from horizontal into vertical or reversed. This fast and easy coil handling solution gets rid of “adventurous” tilting methods that often will endanger the operator. Chains and other lifting aids which damage the coil rims become obsolete. Upenders allow 90 degrees tilting of coils; Combination machines will also rotate 180 degrees. Both can handle up to 25 tons.

Request for a quote

GSW SCHWABE AG

Germany

shock dampening for low operating noise levels absolutely sturdy and warpresistant body design with heavy doublepost guides to smoothly cut even toughest materials with adjustable blade clearance for a most precise cut at any thickness very precise blades made of special steel high operating safety through material guide at entrance and protective cover springactuated hold down clamp (from 250 mm stock width) top/bottom dead center control to monitor blade position counter control mounting bracket hydraulic power units in different sizes electrical control

Request for a quote

GSW SCHWABE AG

Germany

shock dampening for low operating noise levels thanks to a heavy overall frame and the sturdy, warpresistant design with heavy doublepost guides even toughest materials can be cut smoothly with adjustable blade clearance for a most precise cut at any thickness very precise blades made of special steel high operating safety through material guide at entrance and protective cover springactuated hold down clamp (from 250 mm stock width) top/bottom dead center control to monitor blade position counter control mounting bracket hydraulic power units in different sizes electrical control

Request for a quote

GSW SCHWABE AG

Germany

Shock dampening for low operating noise levels Sturdy, warpresistant design with heavy doublepost guides With adjustable blade clearance for a most precise cut at any thickness Very precise blades made of special steel High operating safety through material guide at entrance and protective cover Springactuated hold down clamp (from 250 mm stock width) Top/bottom dead center control to monitor blade position Counter control Mounting bracket

Request for a quote

GSW SCHWABE AG

Germany

Shock dampening for low operating noise levels Sturdy, warpresistant design with heavy doublepost guides With adjustable blade clearance for a most precise cut at any thickness Very precise blades made of special steel High operating safety through material guide at entrance and protective cover Springactuated hold down clamp (from 250 mm stock width) Top/bottom dead center control to monitor blade position Counter control Mounting bracket

Request for a quoteResults for

Straighteners - Import exportNumber of results

65 ProductsCountries

Company type