- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- trim

Results for

Trim - Import export

LEICA MICROSYSTEMS

Germany

The Leica EM TRIM2 is a high speed milling system with integrated stereomicroscope and LED ring illuminator for trimming of biological and industrial samples prior to ultramicrotomy.

Request for a quote

LEICA MICROSYSTEMS

Germany

The Leica EM RAPID milling system for pharmaceutical research enables sample preparation for analysis of active ingredient distribution on solid-dose pharmaceuticals. The instrument, using a tungsten carbide or diamond miller, decapsulates pills without smearing and features adjustable cutting speeds between 300 and 20,000 rpm, defined step-layer removal, low-noise extraction and filtration with a Hepa filter and single or multiple holders.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

L-section for separation of gravel and substrate. Simple installation due to click-connection system. Installed on protection membrane, drainage elements or filter fleeces; connectable to water conduit systems. For roof pitches of up to 5°.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

L-section for separation of gravel and substrate. Simple installation due to click-connection system. Installed on protection membrane, drainage elements or filter fleeces; connectable to water conduit systems. For roof pitches of up to 5°.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

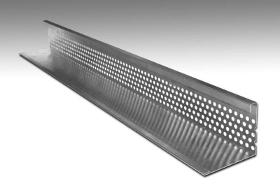

Perforated Edge Trim L-section as border of a green roof. Fixed to the roof membrane via aluminium connection elements. For roof pitches of up to 5°.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Perforated Edge Trim L-section as border of a green roof. Fixed to the roof membrane. For roof pitches of up to 5°.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Perforated gravel retainer L-section as border of a green roof. Fixed to the roof membrane. For roof pitches of up to 5°.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

max. size 24 x 34 cm age 2014 brochure finisher head- / tail trimming square fold of booklet spine max. 1.600 cyles / h (off-load) for inline or offline operation was used inline behind a Konica Minolta system Delivery time: immediately from stock Ref: SD210285A Please ask for price. We ship and install worldwide!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

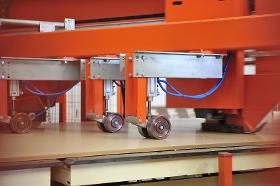

The deburring grinding discs from the FAPI-TRIM series are the ideal tool for deburring on automatic deburring machines (e.g. Weber deburring machines) and are particularly suitable for processing larger series. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The round tubes are manufactured from a coil that is bent and electric resistance welded (ERW). The forming process can be according to EN 10210, which foresees hot forming or cold forming followed by heat treatment, or according to EN 10219, which foresees cold forming without following heat treatments. The finished product is fully killed and welding seam bead is inside and outside trimmed. These products are used to manufacture both welded and bolted structures, in the field of constructions, engineering, industrial constructions, transports, automotive, agricultural machinery and earth moving machinery. The cold finished tubes are particularly suitable for structures at sight or for aesthetical uses, thanks to the surface aspect typical of cold forming. NORMS HOT FINISHED” TUBES EN 10210-1/2 COLD FINISHED” TUBES EN 10219-1/2 INSIDE TRIMMING EN 10217

Request for a quote

B.A.B. AGRARBERATUNG GMBH

Germany

Halal certified BQF Boneless Beef Cube Roll made in Brazil / frozen Beef Trimmings for sale

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• Most popular shape for assembly work, trimming printed circuit boards, also for radio and telephone work • Cutting edges inductively hardened • Precision cutting edge for the finest wires • Tight-fit joint movement • With box-joint and opening spring • Handles coated with plastic • Made of special tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• Most popular shape for assembly work, trimming printed circuit boards, also for radio and telephone work • For gripping small parts and forming wires • Tips bent 45°, smooth inside jaws, edges rounded • Tight-fit joint movement • With box-joint and opening spring • Handles with ergonomically shaped ESD multi-component sleeves, electrically conductive • Made of tool steel, forged, oil-hardened

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming or scoring foils and skins Blade cutting is a very fast, precise and clean process. In the automotive industry, it is particularly well suited for kiss cutting, edge cutting and for cutting notches in foils and leather skins to prepare for edge folding processes. A special form of blade cutting is scoring, i.e. the intentional weakening of leather, plastic foils and form skins to create specific tear lines, such as to allow the release of airbags. Ultrasonic cutting technology allows for even more possibilities in die and kiss cutting for foamed components with appropriate material combinations. This technology allows parts to be cut dust and chip free with a very low noise level.

Request for a quote

FRIMO GROUP GMBH

Germany

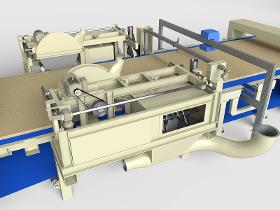

Ideal for trimming and scoring hidden airbag compartments on thermoformed skin. After the fabrication of IP skins through thermoforming, two separate fabrication steps are still needed before foaming. In the first step, the thermoformed skin will be trimmed in the external zone through punching or a blade cutting process. Depending on the requirements, this is where FRIMO's blade cutting equipment comes into operation. In the second step, the skin will be weakened in the airbag area by a blade. By using the new FRIMO FlexTrim Combi Trim Scoring machine, both steps can be realised at once. The skin is positioned in a common component fixture and finished with two different cutting tools. The new system concept, with its flexible design and layout possibilities, offers a variety of options for combinable process and operation groupings. As an example : one 2-station system with two robots, which are equipped with automatically exchangeable cutter heads, and where two different products

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIMO GROUP GMBH

Germany

Good ergonomics and optimal component accessibility Milling can be used to not only create highly complex component geometries, but also to achieve precise cutting depths. It is often used in combination with punching operations to produce component variations or small quantities, such as of instrument panels, center consoles or door panels. FRIMO FlexTrim milling machines have been specially developed to process complex 3-D plastic components. The newest generation of FlexTrim milling machines offers an attractive price/performance ratio. The new rotary table and product fixture concept ensures excellent ergonomic conditions for the operator and optimal component access for the milling robots. The use of multiple product fixtures per station reduces the number of necessary changes, thereby increasing productivity. Through the use of new milling technology with optimized chips, an effectiveness ratio of up to 95 % is possible with appropriate material combinations.

Request for a quote

PROXOMED® MEDIZINTECHNIK GMBH

Germany

Equipment MFT Trim Disc DVD and training guide Areas of use Personal training, fitness studio, physiotherapy practice, rehabilitation centre, clinic Target group Fitness-conscious people, exercise enthusiasts, sportspeople and patients

Request for a quote

ROTH COMPOSITE MACHINERY GMBH

Germany

Trimming machines cover all the needs of the brush industry – from the manually operated AM1 for straight brushes to the electronically driven fully automatic trimming machine. From conical to curved cuts, from horsehair to wire – our range of trimming machines will meet all your requirements.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The mat trimming saw cuts the precompressed mat precisely to the width required. Two motor-adjustable saws, one each on either side of the belt, cut the bre mat to the dened width. The trimming waste is disintegrated and may be recycled to the production process. Features, function Modular design Motor-adjusted saw blades incl. distance measurement Max. trimming waste of 420 mm on either side Max. mat height ex prepress 360 mm Integrated hogger including extraction stub to remove the trimming waste Extraction stub at the saw blade

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The boards are cut o the endless mat in the saw section. The process becomes a discontinuous one that is characterised by cycle times from this point on. The saw section includes the board edge-trimming and saw units. The board is cut by saws that are positioned at right angles to the endless board and that cut straight proportionally to the feed of the press. It is possible to change the tools without interruption to the production process depending on the number of individual units. longitudinal edge trimming device 2 edge-trimming units – no production possible while tools are being changed 2 edge-trimming units with the option for retrotting additional units 4 edge-trimming units for interruption-free changing of the saw blades Bevelling of the endless board after trimming Multi-diagonalsaw Up to two saw beams each with two units, i.e. four saws maximum Number of saws depending on the feed and desired board length

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The trimming saw is installed downstream of the last surface-layer mat former, cutting the strand mat precisely to the required width. Two motor-adjustable saws, one each located on either side of the belt, cut the strand mat to the dened width. The trimming waste is discharged through a hopper and recycled to the mat former bins. Features Motor-adjusted saw blades incl. distance measurement Movable mat edge retainers to ensure high-quality cuts Lateral pressure rollers ex saw compact and smoothen the mat edge Movable extraction system adjustable to mat thickness Advantages Recipe-related adjustment of all adjustable axes Eective strand extraction

Request for a quote

PROFORM GMBH

Germany

Trim strips for covering joints between the window frame and wall. With connecting lug extending on to the wall and adhesive tape cover. Cover strip DK60 with two adhesive tapes and adhesive tape cover on both sides, as a visible profile providing a central joint cover. Acrylate foam tape grade, 1 mm thickness, weather and ageing-resistant, permanently elastic. Can also be supplied coated with Renolit MBAS wood and single-colour decorative finish.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quoteResults for

Trim - Import exportNumber of results

29 ProductsCountries

Company type

Category