- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- valves for the chemical industry

Results for

Valves for the chemical industry - Import export

EWG E. WAGENER GMBH

Germany

Zirconium is a silver-grey, shiny heavy metal. In its pure form it is easy to work, corrosion resistant even at high temperatures and has a very low neutron capture cross section. In addition, zirconium offers good stability against structural damage caused by neutron irradiation and against cavitation by coolant flows. The metal is mainly used pure or alloyed with 1.2-1.7% tin, for corrosion resistant pipes, fittings and valves in the chemical industry. This special alloy is called Zircaloy. Zirconium plays an important role in reactor construction. It is used for fuel element claddings and holders, for the pressure vessel lining, and for all structural components that come into contact with neutrons. In the rocket and jet aircraft industry zirconium is used for the manufacture of combustion chambers and feed lines. In electron and X-ray tubes zirconium is used as getter material.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre-compressed Packing set of specially impregnated PTFE fiber packing Characteristics Ring set made of pure PTFE packing fulfills with a tested leckage of 6.3 x 10 -6 mbar · l/(s·m) the leakage criteria according to VDI 2440 +200 °C with a maximum allowable leakagerate of 1 x 10 -4 mbar l/(sm) and is suitable for temperatures up to +200 °C. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 100 [bar] Temperature without LiveLoading: t +200 °C Temperature with LiveLoading: t +200 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Suitable for Chemical industry Petrochemical plants Approvals TA Luft / VDI 2440 Certificate EU 10/2011 / EG 1935:2004 FDA

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

PTFE Fiber with PTFE Blocking Agent and Silicone Free Run-In Lubricant Characteristics Highest chemical resistance for a packing in rotating equipment Pliable, easily compressible packing Self lubricating, dry running capability Shaft protecting surface hardness of HRC 25 is sufficient Non ageing Operating range Pressure [p max]: 15 bar, Velocity [v max]: 10 m/s Pressure [p max]: 100 bar, Velocity [v max]: 1.5 m/s Pressure [p max]: 100 bar Temperature: t = -50… +280 °C pH: 0 - 14 Density: 1.70 g/cm³ Main application Agitators Mixer Refiner Filter Slow speed Centrifugal pumps Valves, Gate valves Metering valves Suitable for Chemical industry General industry Variant S6SI with Food certification EG 1935:2004 in accordance with EU 10/2011 FDA conformity Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special measurements. 03 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 - 25 mm on 5 kg spool Special...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

High strength ePTFE-Graphite Characteristics Extrusion resistant even with large clearances Form stable, wear resistant, heat conductive and can be used as bull ring Shaft protecting (recommended surface hardness: HRC 25) In high pressure applications die formed rings are recommended Operating range Pressure [p max]: 30 bar, Velocity [v max]: 8 m/s Pressure [p max]: 800 bar, Velocity [v max]: 3 m/s Pressure [p max]: 500 bar Temperature: t = -200… +280 °C pH: 0 - 14 Density: 1.35 g/cm³ Main application High pressure plunger- and dosing pumps Bullrings for mixers, highpressure valves agitators, gate valves and valves Suitable for Chemical industry Petrochemical plants High pressure machine constructions Approvals BAM for liquid and gaseous oxygen 60 °C/15 bar, 40 °C/65 bar, 200 °C/50 bar Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special measurements. 03 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

PTFE-Graphite Fiber with Paraffin Run-In Lubricant Practical useful application data: max. temperature: +180 °C max. pressure centrifugal pumps: 20 bar Characteristics Special lubricating graphite minimizes friction and guarantees greater heat conductivity Shafts or shaft sleeves in HRC 25 recommended Universal PTFE/Graphite packing with good value for money Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 250 bar, Velocity [v max]: 2 m/s Pressure [p max]: 150 bar Temperature: t = -50… +280 °C pH: 0 - 14 Density: 1.65 g/cm³ Practical useful application data: max. temperature: +180 °C max. pressure centrifugal pumps: 20 bar Main application Centrifugal pumps Mixer Kneader Agitators Autoclave Refiner Gate valves Suitable for Chemical industry Power plant technology Pulp and paper industry General industries Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100 % PTFE Tape packing with cover braid and additional outside PTFE Tape Wrap Practical useful application data: max. temperature: +200 °C Characteristics Low coefficient of friction Good adaption to any kind of surface Non ageing or hardening Used as spiral guarantees simple assembly and disassembly in one piece Available in 2-15 mm Operating range Pressure [p max]: 20 bar, Velocity [v max]: 1 m/s Pressure [p max]: 20 bar, Velocity [v max]: 1 m/s Pressure [p max]: 100 bar Temperature: t = -200… +280 °C pH: 0 - 14 Density: 1.45 g/cm³ Practical useful application data: max. temperature: +200 °C Main application Valve Packing, easy to use Suitable for Chemical industry Universal use Installation and maintenance shops

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100% PTFE - Fiber with special PTFE Dispersion and FDA conform Siliconoil impregnated Characteristics Highest chemical resistance for a packing in rotating equipment Pliable, easily compressible packing Self lubricating, dry running capability Shaft protecting surface hardness of HRC 25 is sufficient Non ageing Operating range Pressure [p max]: 25 bar, Velocity [v max]: 2 m/s Pressure [p max]: 250 bar, Velocity [v max]: 1 m/s Pressure [p max]: 500 bar Temperature: t = -100… +280 °C pH: 0 - 14 Density: 1.70 g/cm³ Main application Agitators Mixer Refiner Filter Slow speed Centrifugal pumps Valves, Gate valves Metering valves Suitable for Pulp and paper industry Chemical industry Pharmaceutical industry Food industry Approvals FDA conformity EN 1935:2004 in accordance with EN 10/2011 Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special measurements. 04 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 -...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre-compressed ring-set made of expanded graphite and reinforcement to protect against extrusion Characteristics Packingset made by combining two expanded Graphite grades and designs in order to avoid blow out and extrusion and as well enhance the sealability of this valve sealing set. The set was tested and approved by the AMTEC GmbH Lauffen in Germany. The leakage parameters of 8.6 x 10-3 mbar · l/(s·m) complies with the VDI 2440 at +400 °C, which specifies a maximum allowed leakage of 1.0 x 10 -2 mbar · l/(s·m) (test media helium) and is therefore recommended as a high grade seal system. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 160 [bar] Temperature without LiveLoading: t 400 °C Temperature with LiveLoading: t 400 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Suitable for Power plant technology Chemical industry Petrochemical plants Boiler houses Refineries Approvals TA Luft / VDI 2440 Certificate

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre compressed Packing set of expanded graphite with Inconel Matrix reinforcement and special PTFE coating Characteristics Ring Set made from special high temperature resistant yarn and pore filling cross section impregnation fulfills with a tested leakage rate of 8.4 x 10 -3 mbar · l/(s·m) the leakage criteria of VDI 2440 +400 °C with a maximum allowable leckagerate of 1 x 10 -2 mbar l/(sm) and is suitable for temperatures up to +300 °C. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 100 [bar] Temperature without LiveLoading: t +300 °C Temperature with LiveLoading: t +300 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Control Valves Suitable for Power plant technology Chemical industry Petrochemical plants Boiler houses Approvals TA Luft / VDI 2440 Certificate ISO 15848-1 CC1 ISO 15848 test was conducted with 20,000 mechanical cycles and 2 thermal cycles (RT, +200 °C) and passed with a leckagerate of 6.1 x 10 -4 mg/s/m.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre-compressed Packing Set of specially impregnated PTFE fiber packing Characteristics Ring set made of pure PTFE packing and PTFE compound bull rings fulfills with a tested leakage rate of 4.2 x 10 -5 mbar · l/(s·m) the leakage criteria according to VDI 2440 +200 °C with a maximum allowable leakagerate of 1 x 10 -4 mbar l/(sm) and is suitable for temperatures up to +200 °C. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 100 [bar] Temperature without LiveLoading: t +200 °C Temperature with LiveLoading: t +200 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Suitable for Power plant technology Chemical industry Petrochemical plants Approvals TA Luft / VDI 2440 Certificate

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Carbon Staple fiber with special Graphite Impregnation and silicon free Run In lubricant Practical useful application data: max. temperature: +200 °C Characteristics Volume stable, pressure stable High Cross section density due to special impregnation Excellent Value for money Graphitized all-round packing with Emergency run Capabilities Good wear resistance against abrasive and crystallizing products Recommended shaft surface hardness: HRC 45 Operating range Pressure [p max]: 20 bar, Velocity [v max]: 20 m/s Pressure [p max]: 250 bar, Velocity [v max]: 2 m/s Pressure [p max]: 150 bar Temperature: t = -50… +250 °C pH: 2 - 12 Density: 1.15 g/cm³ Practical useful application data: max. temperature: +200 °C Main application Centrifugal pumps Valves Mixer Kneader Agitators Suitable for Chemical industry Pulp and paper industry Waste water technology Community facilities Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

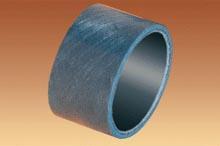

Where to use deva.tex ® deva.tex ® is a high performance self-lubricating sliding material with a glass fiber reinforced carrying layer. The machinable sliding layer consists of fibers which are embedded in epoxy resin. The resin carries PTFE as lubricant for excellent tribological performance. deva.tex ® bearings are available up to 1.000 mm and are characterized by a very high corrosion and wear resistance. They are insensitive to contamination as well as to vibrations and shock loads. In addition to standard dimension, special geometries can be machined. Max. possible outer diameter 1.000 mm Applications Water turbines, earth moving equipment, hydromechanical engineering equipment, agricultural machines, railroad applications, shut-off valves, chemical industry and many more. Structure 1. Sliding layer: reinforced polyethylene fibers embedded in epoxy resin and PTFE 2. Glass fiber reinforced carrier

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.tex ® deva.tex ® is a high performance self-lubricating sliding material with a glass fiber reinforced carrying layer. The machinable sliding layer consists of fibers which are embedded in epoxy resin. The resin carries PTFE as lubricant for excellent tribological performance. deva.tex ® bearings are available up to 1.000 mm and are characterized by a very high corrosion and wear resistance. They are insensitive to contamination as well as to vibrations and shock loads. In addition to standard dimension, special geometries can be machined. Max. possible outer diameter 1.000 mm Applications Water turbines, earth moving equipment, hydromechanical engineering equipment, agricultural machines, railroad applications, shut-off valves, chemical industry and many more. Structure 1. Sliding layer: reinforced polyethylene fibers embedded in epoxy resin and PTFE 2. Glass fiber reinforced carrier

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.tex ® deva.tex ® is a high performance self-lubricating sliding material with a glass fiber reinforced carrying layer. The machinable sliding layer consists of fibers which are embedded in epoxy resin. The resin carries PTFE as lubricant for excellent tribological performance. deva.tex ® bearings are available up to 1.000 mm and are characterized by a very high corrosion and wear resistance. They are insensitive to contamination as well as to vibrations and shock loads. In addition to standard dimension, special geometries can be machined. Max. possible outer diameter 1.000 mm Applications Water turbines, earth moving equipment, hydromechanical engineering equipment, agricultural machines, railroad applications, shut-off valves, chemical industry and many more. Structure 1. Sliding layer: reinforced polyethylene fibers embedded in epoxy resin and PTFE 2. Glass fiber reinforced carrier

Request for a quote

STAIGER

Germany

• Light emitting seals (Flat seal with integrated circuit, LED and transient voltage suppression); • Light emitting sockets (LED, with integrated seal and screw, transient voltage protection); These light-emitting Staiger seals and sockets are above all suited for assuring operational readiness of new and existing installations The light-emitting seals and sockets immediately signalize malfunctions and their precise location. This is particularly advantageous in valve cascades or similar systems with high packing density. Your system’s operational readiness is considerably improved by using the electronic components fitted with LEDs. This is an effective measure to consistently reduce required maintenance costs and time. Owing to their low height and standardized connections, the light-emitting seals and sockets may also be installed in retrofitting.

Request for a quoteResults for

Valves for the chemical industry - Import exportNumber of results

16 ProductsCountries

Company type