- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- indexable inserts

Results for

Indexable inserts - Import export

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

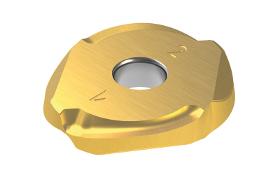

LMT Tools has developed the CopyMax family, specially for the die and mold making industry The latest addition to the family is the one-sided indexable insert CopyMax1. It is an alternative for the reliable CopyMax2 with a two-sided indexable insert. opyMax1 and CopyMax2 prove their advantages above the competition during the roughing and the semi-finishing processes. Both tools are manufactured using the manufacturing process HQS (High Quality Sintering), which is registered for patent approval. For the first time, HQS allows for pressing and sintering a ball nose copy insert complete, resulting in precision sintered cutting edges. In addition to introducing the new indexable insert CopyMax1, LMT Tools has developed new shanks for the CopyMax. A cylindrical steel shank version is available in two different lengths, and the cylindrical bolt-on milling cutter are both new to the program. Both milling systems are designed with internal coolant supply.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

The milling cutters used during roughing in die and mold making have to continuously withstand high levels of stress otherwise process reliability and quality cannot be guaranteed. That is why the CopyMax® product family by LMT Kieninger has been specially designed to handle these extreme conditions. The patent-pending HQS (High Quality Sintering) production process and Nanomold Gold high-performance coating ensure high endurance during roughing and semi-finishing. The double-sided CopyMax®2 indexable insert has already convinced many customers with its up to fourfold increase in service life. The single-sided CopyMax®1 insert is now also available. Users can therefore select the appropriate model depending on to the requirements of the respective component. This definitely increases tool life and process reliability while simultaneous reducing handling.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

The coating of the newly developed CopyMax®2 insert from LMT Kieninger is Nanomold Gold, which is already an indication of top performance in mold and die making. The copy milling insert itself has a new construction design. It has improved cutting and material properties as well as a fully functional second cutting edge. When the first cutting edge is worn, the insert can be turned over and re-used with the same long tool life. Benefits: Identical geometry to the highly efficient WPR-AR copy milling insert. - The stable cutting edge and proven Nanomold Gold coating double the service life per cutting edge - 4 times higher tool life possible by using the 2nd cutting edge. - Highly economic solution for more than 70 % of your applications in forming technology, energy technology and mechanical engineering.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

Highly versatile: The MultiFace H45 PRO4 and P45 PRO8 face-milling cutters enable high material removal rates even on lower performance machines. This is achieved with the highly positive cutting edge geometry of the MultiFace H45 PRO4, which has four cutting edges per indexable insert, as well as the positive cutting edge geometry of the MultiFace P45 PRO8 with its eight cutting edges. The easy cutting cutters can therefore be used for many different applications.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

High feed and short machining times are the advantages of the LMT Fette MultiEdge 2Feed mini in a nutshell. High removal rates are achieved especially when machining hardened or high-tensile materials, even with large projection lengths. These results are delivered by the proven high-feed geometry of the 9 mm small indexable inserts, their positive rake angle, the new LCK10M cutting material with high carbide content and the TiAlN-based high-performance coating. The machining of high-tensile steels up to 63 HRC and chilled cast iron up to 67 HRC presents no problem. The machining time for one type of tempered steel was almost half that of a competitor tool.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ORBITEC GMBH

Germany

Tube squaring machines are necessary to achieve burr-free and right-angled seam preparation for orbital welding. That‘s why Orbitec offers two machines, from the small handy Planfix 40 S to the large Planfix 115 S. The Planfix 115 S is a high-performance tube squaring and chamfering device with angle gear for mobile or stationary use with a mains drive. It has a large viewing window, a chip collector and a feed with 0.1mm scale graduation. Optionally, the device can be equipped with a tool carrier and a double-sided indexable insert holder or the well-known Orbitec L facing tool bits. Package includes exemplary for Planfix 115 S Power 230 V: — Tube clamping attachment — Drive — Tool set — Transport box

Request for a quote

ORBITEC GMBH

Germany

Tube squaring machines are necessary to achieve burr-free and right-angled seam preparation for orbital welding. That‘s why Orbitec offers two machines, from the small handy Planfix 40 S to the large Planfix 115 S. The Planfix 40 S is a powerful and handy squaring device for mobile or stationary use with battery or mains drive. It has a large viewing window, a tool carrier for mounting the inserts, double-sided indexable inserts, and a feed with 0.1mm scale graduation. Alternatively, existing Orbitec facing tool bits can be used without tool carriers. The new inserts have a long service life and can process unalloyed, low-alloy and high-alloy steel quickly and reliably with high precision. Package includes exemplary for Planfix 40 S battery pack 230 V: — Tube clamping attachment — Drive — 2 Li-ion batteries — Battery charger — Tool set — Carrying case

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner powder press and indexable insert automations of the "RPA 3-SC series" automatically remove pressed blanks from a powder press and deposit them quickly and gently in a definable sample. In the "RPA 3-SC1", the transfer of the individual sintering plates and the loading of the blanks is carried out by a SCARA 4-axis robot. The empty sintering plates are placed manually into a sintering plate magazine, removed with a sintering plate gripper if necessary, and fed to the loading position. The robot then moves to a gripper station, deposits the sintering plate gripper, picks up a part gripper, and starts loading the sintering plate. In the "RPA 3-SC2", sintering plates are placed manually on a double conveyor belt. One sintering plate at a time is automatically transported to the loading position via the conveyor belt. The robot immediately starts to load the blanks. Loaded sintering plates are ejected from the loading position and manually removed from the conveyor belt.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The "Metzner RPA 10-SL" is a powerful and flexible press automation system for handling indexable inserts and small ceramic parts for medium to large batch sizes. It has an integrated magazine system for up to ten sintering inserts. Empty sintering inserts are automatically removed from the magazine, loaded and then returned as required. In this way, the powder press automation works independently over a longer period of time without loading and unloading processes leading to a press stop. With its integrated 4-axis SCARA robot, the machine achieves very high system speeds of up to 30 stroke/min. The "RPA 10-SL" is operated conveniently via the integrated control or via the mobile operator terminal. At the push of a button, loaded sintering plates are removed and new ones received. Defined operating data are transferred to the press control via an interface.

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

Only requires a 6.8 mm diameter hole for chamfering Two 3sided indexable inserts provide a cost effective way to get a smooth, chatter free finish Lightweight at only 500g

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

Carbideline consists of CarbideLine-S solid carbide tools, CarbideLine-H hybrid tools and multi-part carbide tooling with CarbideLine-I indexable carbide tools. All CarbideLine tools excel through maximum productivity in their specific fields of application. CarbideLine-H tools are a new addition to the product range. They cover the module range 5 to 12 and are the 1st. choice for rough machining and finishing large lot sizes, where the tools costs using solid carbide milling cutters are too high and the gear cutting quality is too low using indexable inserts. CarbideLine-H tools are also highly suitable for machining high-strength materials up to 1,400 N/mm2 and enable a gear quality up to quality grade AAA. Its preferred area of application is for gears for commercial vehicles, general mechanical engineering and energy technology. In one specific application it was possible to reduce the gearing costs per wheel by 20% with the CarbideLine-H compared with an indexable insert system.

Request for a quoteResults for

Indexable inserts - Import exportNumber of results

12 ProductsCountries

Company type