- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial ovens

Results for

Industrial ovens - Import export

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

The industrial ovens we produce are used to dry the water and chemical particles remaining on the material after the surface cleaning, moreover to finish the chemical reaction of the paint, after painting process. Our ovens are renowned in the sector for their heat homogenization, give the opportunity to long term usage with trust and designed for maximum efficiency in a frame of our respect for nature policy.

Request for a quote

BTF

Belgium

BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, … Furthermore, BTF designs and manufactures furnaces for performing fire resistance testing in approved laboratories, for the certification of materials. These furnaces must provide rates of temperature rise complying with the ISO standards.

Request for a quote

BTF

Belgium

Industrial furnaces BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, …

Request for a quote

BTF

Belgium

Industrial furnaces BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, …

Request for a quote

BTF

Belgium

Industrial furnaces BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, …

Request for a quote

BTF

Belgium

Industrial furnaces BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, …

Request for a quote

BTF

Belgium

Industrial furnaces BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, …

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

In-line conveyor ovens: Pallets pass through the oven one after the other. Automatic batch ovens: The oven is charged with pallets while kept at a temperature below the gelation temperature. After the last pallet has been loaded, the temperature cycle is started for the whole lot. The oven is emptied in a rapid process after the complete temperature profile has been run through. Stack ovens: Pallets are loaded into the oven. When each row has been filled, all the rows of pallets are lifted up by one level. When one row of pallets has reached the uppermost position of a temperature range, it is pushed into the next temperature zone and from here is lowered down in fixed time cycles and unloaded. Serpentine conveyor ovens: Pallets are loaded into the oven in fixed time cycles and pass through the individual temperature zones.

Request for a quote

SILCAP SILICONE

Turkey

Silicone is used in medical devices, automotive applications, many cooking, baking and food storage products, electronics, home repair and hardware, and a host of unseen applications.Silicone rubber is generally nonreactive, stable, and resistant to extreme environments and temperatures from 55 °C to +300 °C while still maintaining its useful properties. We manufacture and provide silicone industrial gaskets solutions suitable for many applications.Our inhouse tool making division is equipped with the latest extrusion technology. The silicone ilicone industrial gaskets can be produced to both standard sizesshapes and custom made shape to suit customer specifications.Due to these properties and its ease of manufacturing and shaping, silicone rubber is used in orings, seals, and gaskets and can be found in a wide variety of products.Silcap Silikon engineers can create custom hardness’s, colors, variety of profile shapes and industry certifications available upon request.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Customers worldwide use Datapaq® temperature profiling and monitoring systems with their powder coating equipment in automotive and industrial powder coating to optimize product quality, reduce waste and prove compliance with ISO9000. When standard and specialty systems will not meet your exact application requirements, Datapaq will build a custom system using Insight™ thermal profiling software, an extensive range of custom barriers and thermocouples, as well as the Datapaq DP5 and Datapaq TP3 data loggers. In addition, Datapaq offers a complete thermal profiling system for real-time data analysis -TM21 Radio Telemetry System. Oven Tracker Insight Software Datapaq powerful Insight analysis software has been designed specifically to convert raw temperature data into meaningful information that can be used to understand, control and optimize your cure process. Complex calculations are simplified, allowing quick and comprehensive analysis.

Request for a quote

REINHARDT GMBH

Germany

Since decades, Reinhardt ovens “Made in Germany” are working day by day all over the world and are estimated by their reliability and long life time. Adapted to your requirements, a Reinhardt oven delivers the best results that are completely designed to your production process. In the temperature range up to 650° Celsius Reinhardt offers the best solutions for almost all requirements, for heating, tempering, drying, hardening, etc. all designed to your space conditions. All heating technologies, from electrical, direct or indirect gas, oil can be applied. Together with the customer, the Reinhardt industrial ovens are integrated into the production flow. In a classical batch oven, hood oven or pass through oven all thermal processes can be applied with the highest accuracy. Requirements such as lifting doors, charging carrier, transport and handling systems can be easily applied.

Request for a quote

MIKROPOR

Turkey

Our Oxygen Generators are a Pressure Swing Adsorption (PSA) system supplying pure oxygen to the airline. Zeolite molecular sieve (ZMS), an effective adsorbent, separates oxygen and other molecules like nitrogen and argon gas in the dry air. Non-oxygen molecules are adsorbed by ZMS under constant pressure, so oxygen is produced. Azot Üretim ve Saflaştırma Sistemleri Our Oxygen Generators are two-bed PSA systems filled with ZMS adsorbers. Including filters, a pressure regulator, valves and assemblies; the oxygen generation process is mainly the separation of oxygen and nitrogen from the clean and dry air. Our brand new MOG Series PSA Oxygen Generators offer an extremely economic way to generate the high capacity and purity level oxygen as customer required. We offer our customer oriented solutions for metal, medical, glass, mining, paper industries; ozone systems, laboratories, fishing farms, industrial ovens etc.

Request for a quote

COSTRUZIONI METALMECCANICHE VALENTE

Italy

Our staff, who are specially trained and kept constantly up-to-date with the latest developments, produce special and automatic machines, production lines and industrial plants, automation and handling systems, prototypes and newly developed machines, material handling and automation systems, equipment and lines. The on-site engineering department at the Nole plant provides specialist consulting on the production of ad hoc industrial machines and systems, which are designed according to customer requirements using advanced 3D design software. Below are some examples of machinery produced : Equipment for the production of foam rubber Automatic cutting lines for rubber Industrial washing facilities Drying ovens Inspection machines Newspaper sorting plants Polymer tempering plants Rolling mills for pasta and kneading machines

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Flowmeters especially for gases The VA 45 variable area flowmeters were designed to measure gases. They can be used, for example, in industrial ovens, forges and furnaces, and protective gas and heating systems. The standardized device design is available with various connections that conform to standards. The glass measuring cone, protected by a metal sleeve with a viewing glass, makes it easy to read the flow directly.

Request for a quote

EUROLINIA

Belarus

EUROLINIA infrared industrial tunnel ovens are designed to rapidly and uniformly heat the surface of cables, wires, polymer pipes and tubes, dry fiber optics and etc. in batch or continuous conveyor production using targeted high-intensity infrared radiation. High efficiency is achieved by concentrating high-intensity infrared radiation and by using a circular reflector that efficiently distributes radiant energy inside the heating chamber. Additional efficiency is gained by installing three-level thermal protection. EUROLINIA tunnels have modular structure: one heating section is 2 meters long, you can connect up to 8 sections in one production line. Maxumum temperarature in the tunnel can reach up to 700C. Tunnels can have multiple separate heating zones and can be equiped with a conveyor. To ensure high-quality, high-precision surface heating, industrial tunnel ovens are also equipped with an automatic heating control system (APCS).

Request for a quote

EUROLINIA

Belarus

EUROLINIA Industrial Infrared Ovens are designed for high-precision surface heating of various materials and products by directional infrared heat. Precise temperature control, sperate heating zones, custom software for your application. Optionally ovens can be equipped with protective steel curtains for instant heating termination or inertia-free start/stop system. Maximum temperature of the infrared ceramic emitters is 750 °C. Maximum temperature inside the oven is 450°C. Maximum power density on the surface of the heated product up to 30 kW/m2. 380V.

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Tunnel type ovens are convection ovens which allows to electrostatic powder coated work pieces to be cured usually around at 180-200°C in 10 minutes, are used in the powder coating systems. Curing oven length is calculated according to the conveyor speed in order to achieve polymerization and curing of the work piece quantities per shift. The powder coating ovens are designed by us according to the shape, quantity and weight of the product to be cured. These ovens are conveyorised, product inlet and outlets are opened designed accordint to the biggest work piece sizes. Oven can be designed as a tunnel, U, S or W-shaped according to the biggestt work piece and the work shop sizes. Electricity, liquid or gas fuel is used for heating up the ovens.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JUKI AUTOMATION SYSTEMS GMBH

Germany

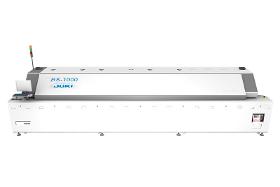

Reflow Soldering Oven JUKI’s RS 800 8 zone reflow soldering oven embodies the best compromise between cost and effectiveness, floor space and energy consumption. With its 8 zones even complex soldering profiles can be constructed. 2 cooling zones ensure a suitable cooling down of the printed circuit boards after the soldering process.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven With its 10 heating zones and 2 cooling zones JUKI’s RS 1000 helps create even ambitious profiles and improve towards a high throughput of printed circuit boards respectively. Top flexibility is therefore guaranteed for future applications as well. In spite of a higher count of heating zones, the energy consumption is low.

Request for a quote

PATRY

France

MAIN GAUGES (IN MM) • 400 • 500 • 600 • 750 • 900 • 1000 • 1440 normal gauge Main uses • work site track • gallery, port and mine tracks • ceramic, oven and brickmaking industries • offshore, load handling • leisure parks FOR ALL RAIL TYPES, WE BUILD FIVE TYPES OF CROSSINGS We build various track systems represented below and intended to be recessed. Vignole rail and grooved check rail forming a groove, welded on flats or metal sleepers.

Request for a quote

BIO NOCCIOLA

Italy

Before being toasted, hazelnuts must withstand rigorous quality controls in order to avoid infiltrations of foreign bodies and low quality hazelnuts. Such controls are carried out manually by our experienced and qualified staff and mechanically with the latest technology in laser and optical screening. Toasting is simply the process of cooking/baking the product in the oven. Our latest generation industrial ovens give us the capability to apply different parameters to this process in order to obtain a product that can fully satisfy our clients requests. The process of roasting not only allows to preserve the hazelnut for longer period of time but also exalts its taste and aroma. The finished product is generally vacuum packed in aluminium bags in order to preserve the delicious flavour.

F.LLI GALLI G. & P. SNC DI RENATO GALLI & C.

Italy

5100 Horizontal Flow Thermostatic Ovens by Galli, suitable for your applications: precise thermostating, heating, drying, polimerization, expansion, cooking, stabilization, tempering, fixing, bonding, heat treatment, accelerated aging, sterilizing, burn-in, inert atmosphere treatments. Made in Italy Temperature range from T.Amb. +10°C to +120°C, +260°C, +350°C Standard Sizes and volumes from 300L to 3000L Customized Sizes amd BiSpoked Volumes to fit your your specific requirements.

Request for a quote

PBS POWER EQUIPMENT, S.R.O.

Czech Rep.

Monoblock burners (power range 50 kW – 11 000 kW) can be deployed on many various applications: a) boilers (warm/hot water, steam) from the smallest stand-alone boilers located in building´s basement (apartments building, block of flat) through bigger boilers (in-house boiler room at e.g. hospitals, airports, hotels, public buildings, bigger buildings and other objects with no central heating presence) to the biggest boilers located in central heating sources (big boiler rooms with pipe distribution network to remote objects). Boiler´s media: Water (warm/hot), Steam (low/mid/high pressure), Oil b) air heaters (air/air, water/air exchangers) c) ovens/furnaces (generally) d) dryers (generally) e) food industry (bakery, brewery, sugar refinery, … ) f) industrial drying furnaces (stone, wood, …) g) paper industry – drying oven h) communal waste incinerators i) composting and sanitary process

PBS POWER EQUIPMENT, S.R.O.

Czech Rep.

Application a) boilers (warm/hot water, steam) from the smallest stand-alone boilers located in building´s basement (apartments building, block of flat) through bigger boilers (in-house boiler room at e.g. hospitals, airports, hotels, public buildings, bigger buildings and other objects with no central heating presence) to the biggest boilers located in central heating sources (big boiler rooms with pipe distribution network to remote objects). Boiler´s media: Water (warm/hot), Steam (low/mid/high pressure), Oil b) air heaters (air/air, water/air exchangers) c) ovens/furnaces (generally) d) dryers (generally) e) food industry (bakery, brewery, sugar refinery, … ) f) industrial drying furnaces (stone, wood, …) g) paper industry – drying oven h) communal waste incinerators i) composting and sanitary process j) ceramics production (kaolin) k) powder color coating furnace l) glass furnaces m) rubber industry etc.

AZTEK FOOD

Turkey

Organic dried fruits. Air-dried in industrial ovens using clean geothermal energy.

Request for a quote

AMARC (UK SALES & TECHNICAL AGENT)

United Kingdom

Manufacturers of Industrial Ovens for heating of drums and IBC's. Temperature ranges >100 degC and >150 degC. Electric, Steam,Gas or Thermal Oil heating systems, with air circulation. Ovens sizes from 4 drums/1 IBC's to 48 drums/12 IBC's. For UK enquiries contact Richard Davies on 07792 929 231 or email richard@industrialovens.co.uk

Request for a quote

THERSER (UK) LTD

United Kingdom

Industrial furnaces and ovens form a significant part of Therser UK’s global business. Therser’s skilled and experienced engineering team combined with Therser’s many years’ experience in supplying a range of furnaces to customers around the world who operate in a variety of industries, ensure that you can be confident of the operational and quality benefits a Therser furnace provides, along with our renowned commitment to after sales services such as maintenance and repair services and the supply of a full range electrical, mechanical and insulation spares and replacement parts. Therser UK have successfully supplied furnaces and ovens around the world for applications including Heat Treatment, Aerospace, Foundry and Fabrication. We are also well equipped to develop thermal solutions for new and emerging technologies in close partnership with our customers from the whole industrial spectrum.

Request for a quoteResults for

Industrial ovens - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Ovens, kilns, furnaces and hearths, industrial (10)

- Electric ovens (6)

- Infrared tubes (3)

- Burners, industrial (2)

- Furnaces, ovens and kilns, electric (2)

- Industrial furnaces (2)

- Chemicals - Basic Products & Derivatives (1)

- Coating machinery (1)

- Filtering equipment and supplies (1)

- Heat treatment furnaces (1)

- Laboratory equipment and instruments (1)

- Nuts (1)

- Organic food (1)

- Paint drying ovens (1)

- Paint spray guns and accessories (1)

- Rolling mills - machinery and installations (1)

- Silicones (1)