- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sludges

Results for

Sludges - Import export

MITA WATER TECHNOLOGIES

Italy

The flow of oil and water is introduced to the tank and distributed in a homogeneous way across the whole cross-section. They are composed of a containment tank which can be manufacturedfrom treated and painted carbon steel or AISI 304 stainless steel; lamellar pack with parallel channels in rigid polystyrene, stabilized agains UV radiation. Special materials and executions are available on request. Typical applications: first fall rain water, petrochemical plants, mechanical workshops, refineries and depots of hydrocarbons, washing of vehicles, land reclaim, refuse handling centres. -High solid-liquid separation efficiency -Simplicity of installation and operation -Compact execution -Low first costs and plant management costs

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The flow of oil and water is introduced to the tank and distributed in a homogeneous way across the whole cross-section. They are composed of just the parallel channel lamellar pack in rigid polystyrene, stabilized against UV radiation, closed in an AISI 304 containment frame; they are normally employed for housing in concrete tanks specifically built for the purpose of holding lamellar packs. Features Available height: 0,85 m Available widths: from 0,60 m to 2,20 m Available lengths: from 1,00 m to 3,00 m -High solid-liquid separation efficiency -Simplicity of installation and operation -Compact execution -Low first costs and plant management costs

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The flow of water and sludge coming from the previous phases of treatment (whether biological or physical-chemical) is introduced into the intermediate zone of the tank, just below the lamellar pack. Lamellar pack single-piece clarifiers for the sludge settling. They are composed of: containment tank which can be manufactured from, at choice, treated and paintedcarbon steel or in AISI 304 stainless steel; lamellar pack with parallel channels in rigid polystyrene, stabilized against UV radiation; surface discharge trough (with weir) in AISI 304; intermediate distributor of the feed flow. Special materials and executions are available on request. FM – L SERIES (11,30 m2/m3 equivalent surface) Typical applications: secondary clarification of biological sludge, drinking water plants, upgrading of existing clarifiers, rain water treatment. -High solid-liquid separation efficiency -Simplicity of installation and operation -Compact execution -Low first costs and plant management costs

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The flow of water and sludge coming from the previous phases of treatment (whether biological or physical-chemical) is introduced into the intermediate zone of the tank, just below the lamellar pack. Lamellar packs with frame for sludge removal. They are composed of the parallel channel lamellar pack in rigid polystyrene, stabilized against UV radiation, closedin an AISI 304 containment frame; they are normally employed for the upgrading of existing clarifiers or for housing in concrete tanks specifically built for the purpose of holding lamellar packs. F – L SERIES (equivalent surface 11,30 m2/m3) F – I SERIES (equivalent surface 14,90 m2/m3) F – S SERIES (equivalent surface 20,00 m2/m3) -High solid-liquid separation efficiency -Simplicity of installation and operation -Compact execution -Low first costs and plant management costs

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

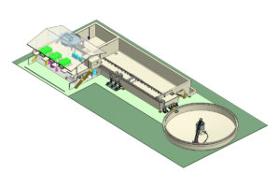

Aerobic type plants. Total Oxidation Activated Sludge Reactor. Moving Bed Biofilm Reactor. Combined Reactor. Membrane Bio Reactors. Water and Air Mixing. Dissolved Air Flotation unit.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECNO AZZURRA S.R.L.

Italy

ll standard tecno azzurra machines are ce marked and ready for use. Standard configuration: base structure made of steel, protected by special paint and access ladder to upper part of machine water storage tank made of polypropylene [version sf 1] or aisi 304 stainless steel [version sf_2, sf_4] water valves with means for positioning bag / filter probe for monitoring maximum water level in tank unit for connection and control of compressed air necessary for an adequate mixing of water with flocculating product [flocculating product not included in supply] electric immersion pump for transfer of water to be treated from painting booth to sludge separator

Request for a quoteResults for

Sludges - Import exportNumber of results

7 ProductsCompany type