- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser drills

Results for

Laser drills - Import export

3D-MICROMAC AG

Germany

Besides the processing of rigid and flexible materials on rigid substrates, we also offer the processing of flexible materials using sheet-to-sheet or roll-to-roll processes: - Laser micro structuring and ablation - Laser processing “on-the-fly” or “step and repeat” - Roll width up to 300 mm possible

Request for a quote

3D-MICROMAC AG

Germany

Applications: - Laser cutting, dicing, and filamentation - Laser drilling – available as trepanning or percussion process - Laser micro structuring and ablation, e.g. with FSLA technology - Laser micro engraving, both on the substrate surface and as sub surface engraving in transparent materials Laser-Lift-Off (LLO) using DPSS laser and scanner systems Materials: ceramics, metals, polymers, glass materials, semiconductors, compound material

Request for a quote

3D-MICROMAC AG

Germany

Applications: - Excimer Laser-Lift-Off using line-beam systems - Laser drilling and ablation using scanner systems or mask projection - Laser engraving of optical materials - Materials: polymers, polymer compounds, glass materials

Request for a quote

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

Laser Drilled Tubes

Request for a quote

STEEC

France

Wire spark erosion, laser micro-cutting, micro-milling and micro-drilling STEEC is also involved, both as a subcontractor to numerous SMEs and agencies in the metallurgy and mechanical engineering sectors which very often engage in subcontracting activities themselves. STEEC enables these players to respond to invitations to tender that involve meeting precision micro-machining requirements for which they are not equipped. The wide variety of precision micro-machining operations which STEEC offers is highly beneficial to these SMEs and agencies, which are able to offer a comprehensive service in micro spark erosion, laser micro-cutting, micro-drilling and milling.

Request for a quote

STEEC

France

STEEC, an eligible company approved for research tax credit, is partner to numerous prestigious research centres such as the CNRS (National Scientific Research Council) and the CEA. The company also collaborates very regularly with university research centres in France and abroad. STEEC assists the researchers in their development by providing them with the possibility of applying leading edge technologies in micro-machining, such as laser micro-cutting or micro-drilling by spark erosion.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

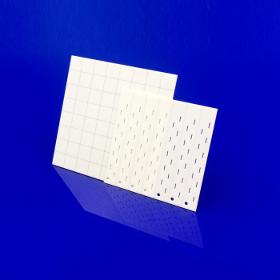

The Aluminum oxide (Al2o3 96%) ceramic substrate are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. The Maximum dimension of ceramic plate is 138x138mm and the thickness of ceramic plate ranges from 0.25 to 1.0mm. Alumina Ceramic Substrate Features: > High reliablility and sfety; > High density and mechanical properties > High electrical and thermal loading perormances > Low dilelectic loss and other characteristics Alumina ceramic substrate / plate specification: 10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. Can be made according to your requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

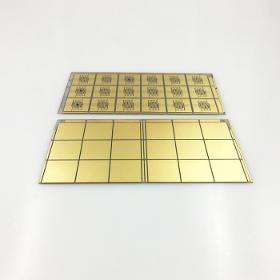

DPC Ceramic Substrate Advantages: > In terms of shape processing, DPC ceramic substrate needs to be cut by laser, the traditional drilling and milling machine and punch machine can not be accurately processed, so the combination force and line width is also more fine. > The crystal performance of the metal is good; > The flatness is good; > The line is not easy to fall off; > The line position is more accurate, the line distance is smaller, reliable and stable, can be through the hole and other advantages.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

DPC (Direct Plated Copper) Mainly by evaporation,magnetron sputtering and other surface deposition process to carry on the substrate surface metallization,first under the condition of vacuum sputtering,titanium,and then is copper particles,the plating thickness,then finish making line with ordinary PCB craft,and then to plating/electroless deposition way to increase the thickness of the line, the preparation of DPC way contains vacuum coating,wet deposition,Exposure development, etching and other processes. Advantages: >In terms of shape processing, DPC ceramic plate needs to be cut by laser, the traditional drilling and milling machine and punch machine can not be accurately processed, so the combination force and line width is also more fine. >The crystal performance of the metal is good >The flatness is good >The line is not easy to fall off >The line position is more accurate,the line distance is smaller, reliable and stable, can be through the hole and other advantages.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Machine Parts manufacuring more than 20years, We have all kinds of processing equipment, to meet the needs of turning, milling, drilling, boring, knurling, hobbing and other processing. Material: Aluminum,Stainless Steel, carbon steel,Brass,etc Technics:Lathe turning,CNC turning,CNC milling,Tooling Milling, Wire cutting,Laser Cutting,Drilling,Boring hole,Cylindrical Grinding,etc Finished by : Zinc plating,chrome plating,nickel plating for carbon steel parts,Passivating for stainless steel parts,Anodizing for Aluminum Parts,Painting,Powder coating, surface polishing… If you have any machine parts want to custom producing in China, welcome send a inquiry to us.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China CNC machining services, custom quality Aluminum machined Parts according to customer’s drawing or samples in large or small volume. Material: Aluminum,Stainless Steel, carbon steel,Brass,etc Technics:Lathe turning,CNC turning,CNC milling,Tooling Milling, Wire cutting,Laser Cutting,Drilling,Boring hole,Cylindrical Grinding,etc Finished by : Zinc plating,chrome plating,nickel plating for carbon steel parts,Passivating for stainless steel parts,Anodizing for Aluminum Parts,Painting,Powder coating, surface polishing… Professional CNC Milled Parts Manufacturers from China, if you have any machine parts want to custom producing in China, welcome send a inquiry to us.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Metal Machine Parts manufacturers provide high precision CNC machining services, custom quality of CNC machined Parts according to customer’s drawing or samples. Material: Aluminum,Stainless Steel, carbon steel,Brass,etc Technics:Lathe turning,CNC turning,CNC milling,Tooling Milling, Wire cutting,Laser Cutting,Drilling,Boring hole,Cylindrical Grinding,etc Finished by : Zinc plating,chrome plating,nickel plating for carbon steel parts,Passivating for stainless steel parts,Anodizing for Aluminum Parts,Painting,Powder coating, surface polishing… Professional Machine Parts Manufacturers from China, if you have any machine parts want to custom producing in China, welcome send a inquiry to us.

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

We are very suitable for large cnc machining parts. Max Dia 800 mm Material: Stainless Steel, carbon steel,Brass,Aluminum etc Technics:Lathe turning,CNC turning,CNC milling,Tooling Milling, Wire cutting,Laser Cutting,Drilling,Boring hole, etc Finished by : Zinc plating,chrome plating,nickel plating for carbon steel parts,Passivating for stainless steel parts,,Anodizing for Aluminum Parts,Painting,Powder coating, surface polishing… All of our products are customized by customer's drawing, please feel free to send us your inquiry.

Request for a quote

DAREVIE

China

Antislip Heel Lining breathable Insole–keep Your Feet Cool Dry elastic Material–soft Comfortable Wear safe Durable Reinforced Toe breathable Mesh Keep Cool Dry laser Drilling double Magic Veclro small Hang Loop nonslip Hang Strip logo Reflective Design 1pair Size 42≈490g 37% Lighter Than Normal Shoes level 10 Solid Hard Carbon Sole wide Lock Adjustment 3 Ventilation Drain Holes replaceable Hind Foot Nails

Request for a quote

3D-MICROMAC AG

Germany

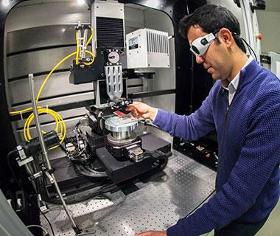

3DMicromac‘s microPRO™ is an adaptable laser micromachining system mainly used in industrial production. Its high versatility makes the system perfectly suited for industrial laser micromachining tasks such as laser structuring, cutting, and drilling applications. Furthermore, it is suitable for a variety of materials, e.g., metals, alloys, transparent and biological substrates, ceramics, and thin film compound systems. The microPRO™ is available with an automatic handling system for wafers, cassettes, trays, etc The microPRO™ enables the laser processing of various substrates. Due to the integration of different technology modules, the platform can be adapted to customers’ requirements. Configuration packages may include High speed cutting Drilling Engraving Structuring and modification Laser Lift Off (LLO) Cylindrical machining Customized solutions

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac‘s microSTRUCT™ C is a highly flexible laser micromachining system predominantly used in product development and applied research. Superior flexibility makes the system ideally suited for laser structuring, cutting, drilling and welding applications on a variety of substrates, e.g. metals, alloys, transparent and biological material, ceramics and thin film compound systems. The microSTRUCT™ C offers a maximal degree of freedom regarding the positioning of the substrates. Flexible, stable and repeatable machining results Two independent and free configurable working areas with various optical setups Open system concept for the integration of different laser sources High range of software functions (Masterscript) User friendly, flexible, upgradeable system

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The millGrind series is specially developed for the requirements of machining in the turbine industry as multiple technology solution in one set-up. The modular machine system in travelling table design allows an individual configuration of the machine according to the customers' needs. Automatic tool and diamond roll changing allows the machining to machine with — Al-oxide, CBN and diamond grinding wheels — Drills — Milling cutter — Laser cladding — Measuring of the unfinished workpiece — Measuring of the machine workpiece including rework in one set-up. This guarantees that all machined surfaces run to each other and errors are avoided by repeated re-chucking. In addition to the machining of new blades and vanes for rework a laser cladding device can be added. This allows the measuring, cladding and grinding or milling of the worn areas.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Laser drills - Import exportNumber of results

17 ProductsCountries

Company type

Category

- Laser - cutting and welding machines (5)

- Ceramics, industrial (2)

- Milling - steels and metals (2)

- Adjustment - machine tools (1)

- Ceramics (1)

- Gears (1)

- Import-export - medical and surgical equipment (1)

- Mechanical engineering - custom work (1)

- Motorcycle clothing (1)

- Research and development of new materials (1)

- Steels and metals - machining (1)