- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- loading robots

Results for

Loading robots - Import export

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

Dolfin KNV series conveyor belt washing machines are parts washing machines used for washing parts produced in series in large quantities. The parts placed at the entry point are moved towards the exit point of the device by means of the conveyor. The parts guided on the conveyor line are washed with high pressure, pre-washing, washing, rinsing, spraying with passivation liquids. At the end of the cleaning process, these parts are dried with pressurised hot air and discharged at the exit point. If desired, it can be integrated into production processes and robotic loading and unloading options are also available. While the entire device is fully automatic, all washing details are parametric. Cleaning is provided at any desired level by means of spray nozzles specially designed according to the part geometry.

Request for a quote

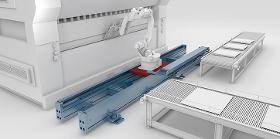

ROLLON GMBH

Germany

Shuttle system for moving robots and heavy loads for long distances with high dynamics. The motion system is available with recirculating ball guides or rollers while the driving system has been designed with rack and pinion. The shuttle is equipped with adjustable ties to achieve alignment even on irregular surfaces. Cable carrier and dampers at the stroke end are included. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

SAMSYS GMBH

Germany

The EasyPalletizer from EasyRobotics is a stationary palletizing robot for loading pallets with cardboard boxes or workpieces. The system is positioned on a conveyor belt. Then the robot picks up the cardboard box or the workpiece with a gripper. Depending on the proramization, it then sets it down on the pallet according to the customer’s requirements. The integrated ER+ software facilitates the programming of the sequence. Structure In combination with the Universal Robots robot UR10e the palletizer is available in different versions: On the one hand, the EasyPalettizer can be equipped with a base with lift. This makes it possible to move a stroke of 265 mm with the robot. Crates and workpieces can be stacked even higher on the pallet. Furthermore, it is possible to install a fixed base. This limits the standard height of the robot to 855 mm. In addition, the base can also be completely dismantled. This is useful if the palletisation will not reach great heights.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Ideal automation solutions for loading and unloading of parts on machining centres, presses, measuring stations, etc… Convenient, accurate, repeatable and reliable! The CLA Robot Cell is composed of the following: - A polyarticulated robot or scara with specific grippers - A camera device for part recognition - Automatic camera calibration - Parts loading/unloading system - Protection (cage, mats, detection, etc) - Each application is studied and simulated in order to define the ideal solution - Microplates screening. CLA is a center of expertise of Mitsubishi robots

Request for a quote

SPIROL

Germany

SPIROL manufactures several different types of Moulded-In Compression Limiters that are designed to be installed into the plastic assembly during the moulding process. When moulding Compression Limiters into the plastic assembly, the moulding time is increased as the operator or a pick-and-place robot must load each Compression Limiter over the core pin(s) prior to closing the mould cavity. Precise placement of the Moulded-In Compression Limiter over the core pin is required; otherwise mould damage can occur. SPIROL Standard Moulded-In Compression Limiters include: The Series CL500 Moulded-In, Series CL460 Moulded-In - Oval, Series CL600 & CL601 Aluminum and Series CL800 & CL801 Brass.

Request for a quote

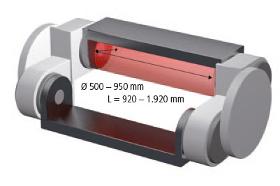

SAMAG MACHINE TOOLS GMBH

Germany

PENDULUM CHANGER – GOOD FROM EXPERIENCE. The W-axis principle, established by SAMAG since 1995, enables workpiece loading to be carried out parallel to production times. The workpiece carrier table is moved in the swivel drive from 0 – 180°. This means that the next loading and unloading of workpieces can take place during processing. Efficient and useful also for robot-assisted loading.

Request for a quote

SCHNELL SPA

Italy

Robotic plant for the production of prefabricated sandwich panels made up of one or more assembling machines working side by side fed by a robot that loads the produced mesh and the polystyrene sheets that have already been cut. Once assembled, another robot placed at the end of the machine, unloads, stacks and binds the polystyrene panels to be used as main walls, partitions and infill walls of prefabricated and industrial buildings.

Request for a quote

REP INTERNATIONAL

France

REP AUTOMATED SOLUTIONS Automation is adapted to the needs and objectives of each customer. An infinite number of possibilities for the following operations Feeder channels Evacuation Flash and gum cutters Evacuation Spraying of release agent and / or cleaning of the mold Loading of inserts Demoulding of finished parts Visual control of conformity and many others... 3 levels of automation possible o Operator assistance Insert loader o Partial automation Demoulding kit (front, rear top, rear bottom, etc.) o Total automation Robotic cell, brushing on horizontal presses, etc.

Request for a quote

REP INTERNATIONAL

France

TYC 22 Press The French company DubourgelGrange is renowned for the quality of its sanitary product range. The factory has fully automated "REP Tung Yu" machinery equipped with handling units and robots (loading and unloading), which operate in 3 shifts for the major part 7 days a week. These machines are used to produce highend toilet covers and seats made in thermoset resin (ureaformaldehyde).

Request for a quote

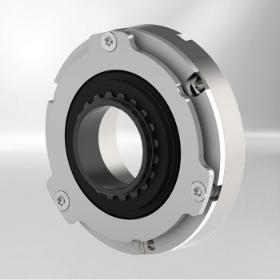

KENDRION (VILLINGEN) GMBH

Germany

The spring-applied brakes which are ideally suited for robotics is designed for robotics solutions and loads of up to appr. 20 kg, but it can also be used in other applications requiring small geometrical dimensions. With regard to their power density the slim single-disc brakes are flatter and lighter than the market standard, and due to their large inner diameter they are well suited for hollow-shaft drives. This makes them perfect for applications in lightweight robots with integrated drives. There is a growing demand for safety technology in order to avoid injuries by collisions, especially if the control technology or even the power supply fails. In this case electromagnetic brakes are usually the method of choice. As safety brakes they bring moving masses to a stop, keep loads in position and therefore prevent humans and material assets from being affected.

Request for a quote

SEIDEL INDUSTRIAL EQUIPMENT CO., LTD.

China

The Semi-Automatic Cleaning Machine is designed for fully automatic robot manufacturing lines. This machine features an automatic opening and closing door. The workpiece to be cleaned from oil, coolant, chips, and other residues is loaded and unloaded by a robot. The cleaning process is semi-automatic. Inside the processing chamber, is placed an air gun as well as a spray gun. The workpiece table can easily be turned by hand to reach all areas of the workpiece. This machine performs soft cleaning by circulating the cleaning fluid in the process tank and rinsing and drying the workpiece. Select from a range of different programs to provide the best cleaning results.

Request for a quote

SEIDEL INDUSTRIAL EQUIPMENT CO., LTD.

China

The Semi-Automatic Cleaning Machine is designed for fully automatic robot manufacturing lines. This machine features an automatic opening and closing door. The workpiece to be cleaned from oil, coolant, chips, and other residues is loaded and unloaded by a robot. The cleaning process is semi-automatic. Inside the processing chamber, is placed an air gun as well as a spray gun. The workpiece table can easily be turned by hand to reach all areas of the workpiece. This machine performs soft cleaning by circulating the cleaning fluid in the process tank and rinsing and drying the workpiece. Select from a range of different programs to provide the best cleaning results.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner powder press and indexable insert automations of the "RPA 3-SC series" automatically remove pressed blanks from a powder press and deposit them quickly and gently in a definable sample. In the "RPA 3-SC1", the transfer of the individual sintering plates and the loading of the blanks is carried out by a SCARA 4-axis robot. The empty sintering plates are placed manually into a sintering plate magazine, removed with a sintering plate gripper if necessary, and fed to the loading position. The robot then moves to a gripper station, deposits the sintering plate gripper, picks up a part gripper, and starts loading the sintering plate. In the "RPA 3-SC2", sintering plates are placed manually on a double conveyor belt. One sintering plate at a time is automatically transported to the loading position via the conveyor belt. The robot immediately starts to load the blanks. Loaded sintering plates are ejected from the loading position and manually removed from the conveyor belt.

Request for a quote

PERO AG

Germany

The compact KDA tunnel units cater for high throughput rates combined with excellent cleaning and drying. They have been designed for the treatment of parts of many different geometries and sizes. The KDA is available with belts of various widths (200/500/650 mm) and a range of features and accessories to cater for many different cleaning tasks. The KDA is available as 1, 2 and 3bath unit. Cleaning with aqueous media (acidic, neutral or alkaline) Spray cleaning unit for wide range of parts High throughput rate Compact, durable design Available as 1, 2 and 3bath unit with loading of the unit via Robot loading Manualm loading Construction side conveyor technology

Request for a quote

ASG, DIVISION OF JERGENS, INC.

Italy

OM Series Manual Screw Presenters Accommodates wide variety of screw sizes by plugging in interchangeable rails Large Storage Capacity Screw scooping chamber holds up to 300cc Speedy Screw Pickup Radial Indexing escaper function loads three screws in a row for fast and continuous feeding Motor overload stop function; protection circuit for reverse power protection Screw sizes from M2 to M6 Only for use with ferrous screws up to 25mm long (head included) Interchangeable rail allows you to switch screw sizes with ease

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-H5 (H) is a compact, high-speed handling robot for small loads. A larger free space in the area of the joint creates a large arm space. Like all robots in the FD series, the H5 model also has collision protection through improved fault detection / elimination. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. The most important technical data: Number of axes: 6 Working range (P-Point): R 866 mm Max. payload capacity: 5 kg Positional repeatability: +/- 0.05 mm Drive System: AC Servo Motor Drive Power: 1440 W

Request for a quote

VELTRU AG

Switzerland

2-axis execution Top mounting Work range: y = 1000 mm, z = 300 mm Payload: to 6 kg For standard applications, VELTRU offers a toploading application ready to use. As all VELTRU applications, the open source PLC program could be adapted to specific customers' needs. For standard applications, the setup and commissioning can be done by interactive GUI only, without any programming. Contact us for more details!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CIMAT

Poland

Suitable for a manual operation by operator, Suitable for an automatic cell with a robot load/unload, Suitable for an automatic conveyor production, Wheel presence sensors, Imbalance compensation of a spindle, Ergonomic size of the machine, Sophisticated fluids drain system with reservoir, Spindle protection system from metal chips, Automatic clamping of a wheel hub with a heavy duty pneumatic clamping chuck, Automatic brake and wheel positioning, Fastest balancing cycle time, Fastest tool changeover time, Made of wellknown brands heavy duty components, Servomotor as a spindle drive motor, Software capabilities Valve compensation feature, The best quality, automatic display, Password protection access for operator and shift manager, Any language possible, Industry 4.0 compliant, Static and dynamic imbalance display, Autotest and selfcalibration, Data transfer and communication with master station, CSV file data creation Sophisticated remote diagnostic and support software .

Request for a quote

KUNLUN COMMUNICATION & INDURSTRIAL NETWORKING INTEGRATION CO., LTD.

China

KL2100-F-4 robot has a load of 100kg. It is a heavy-duty palletizing robot, which is widely used in various chemical loading and unloading, assembly line palletizing and other occasions.The picture shows the scene of the chemical raw material feeding assembly line provided by the company for a customer. A robot is responsible for the whole assembly line, freeing workers from heavy work and solving the problem of recruitment at this position of the enterprise

Request for a quote

KUNLUN COMMUNICATION & INDURSTRIAL NETWORKING INTEGRATION CO., LTD.

China

KL 1850-3C-4 robot has a load of 30kg, which can be used for loading and unloading of a single press, or for loading and unloading of multiple presses to realize the assembly line stamping operation.The picture on the right shows our company providing an assembly line stacking solution for a customer. The size of the customer's card is 1.1m × 1.1m, the required stacking height is 1.6m, and one robot can stack two pallets at the same time, greatly improving the efficiency of flow production and saving labor.

Request for a quote

KUNLUN COMMUNICATION & INDURSTRIAL NETWORKING INTEGRATION CO., LTD.

China

KL 1500-C-4 robot has a load of 10kg and is mainly used for assembly line stamping.The picture shows the working site of the punching line provided by our company for a customer. This type of robot can carry out loading and unloading in a large range in a small environment, greatly improving the production efficiency.

Request for a quote

VELTRU AG

Switzerland

High-throughput production with more than one robot working in line requires a line controller. The VELTRU L10 line controller provides modules to coordinate several robots working on a shared flow or products. The software modules for line control allow to synchronize, centrally visualize and operate multiple robot and other devices. The main features include communication of product information between robots, functionality for load balancing in multi-robot lines and the possibility to access the visualization of different applications on one or multiple screens. The L10 line controller functionality may be installed on a dedicated controller or may be included into the application of one C10 robot motion controller.

Request for a quote

IMOBERDORF AG

Switzerland

The imo-smart is a highly-flexible, versatile rotary transfer system. 4 to 16 machining stations with up to 22 or more spindles ensure fastest setup times. The imo-smart provides you with a ready-to-use machining solution, tailored to your specific requirements and with a wide range of applications. The parts feed is carried out from bar stock, by means of load handling, robot or manually. With a reproducibility of ± 0.003 millimetres, the imo-smart is one of the most precise rotary transfer machines in the world. The imo-smart is designed to be a highly flexible and versatile solution. The excellent accessibility allows adjustments to be made in record time. The 3-axis E-80-CNC unit meets the most common needs: drilling, milling, reaming and tapping. It can be equipped with two spindles and installed horizontally or vertically. This unit can also be used on the imo-compact and the imo-space

Request for a quote

IMOBERDORF AG

Switzerland

On an area of only 9 square metres at a height of 2.30 metres, the imo-compact unites to form a complete, highly-productive rotary transfer system: The imo-compact controls 4 to 8 machining stations with up to 14 spindles per CNC. The parts feed is carried out optionally from bar stock, by means of load handling, robot or manually. The reproducibility of ± 0.003 millimetres makes the imo-compact one of the most precise rotary transfer machines in the world. The imo-compact unites all the elements of a rotary transfer machine. Even the smallest platform offers optimum accessibility. The 3-axis E-97-CNC unit meets the most common needs: drilling, milling, reaming and tapping. It can be equipped with two spindles and installed horizontally or vertically. This unit can also be used on the imo-smart and the imo-space The imo-rot corresponds to the 4th axis: the C-axis

Request for a quote

IMOBERDORF AG

Switzerland

imo-space is Imoberdorf's biggest rotary transfer system in terms of productivity and functional possibilities. Designed on 6 to 20 machining stations with up to 45 or more spindles, the imo-space has enormous production potential. The imo-space provides you with a ready-to-use machining solution, tailored to your specific requirements and with an enormous range of applications. The parts feed is carried out from bar stock, by means of load handling, robot or using Pick & Place. At the same time, the reproducibility of ± 0.003 millimetres makes the imo-space one of the most precise rotary transfer machines in the world. The imo-space meets the highest demands for functionality and productivity. With this large platform, the possible applications are pushed to the extreme. The 3-axis E-88-CNC unit meets the most common needs: drilling, milling, reaming and tapping. It can be equipped with two spindles and installed horizontally or vertically

Request for a quote

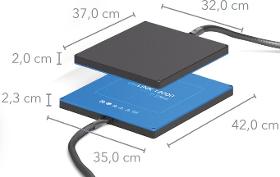

WIFERION - A PULS BRAND

Germany

As a system provider of charging and storage technology, we are presenting our inductive fast charging system etaLINK 12000 for the first time on these pages. The solution enables in-process charging of the lithium-ion batteries of driverless transport systems (AGVs / AGVs), industrial trucks (FFZ) and mobile robots. Loading processes can be flexibly integrated into the intralogistic processes. The scalable energy solution is the world’s first contactless battery charging system with an output of 12 kW and an efficiency of 93%. The result is fully automated charging processes and vehicle availability increased by up to 30%.

Request for a quote

MCT AUTOMATED SMART STORAGE SYSTEMS, VERTICAL STORAGE,LIFT,CAROUSEL,AS/RS,TDM,TQM,ERP,INDUSTRY4.0,

Turkey

ROBUS standard machine feeding system is a robotic automation system that reduces labor costs by up to 90% and increases production numbers by up to 60%. The simplicity of Robus' design is reflected in its ease of use. In minutes, you can adapt a new part and switch to unmanned work.

Request for a quote

BENG ROBOT TEKNOLOJILERI A.S.

Turkey

We increase production speed by eliminating waiting times that reduce productivity in machine loading and unloading processes that do not require a high level of expertise. In addition we eliminate HSSE risks such as press feeding.

Request for a quote

TERCIEL

Luxembourg

Packsoft for your packaging robots. With Packsoft you get the best packaging plans for your items. You can customise them in many ways. And it’s also child’s play to export the coordinates of the palletised objects to transfer all the data to your palletising robot’s PLC. The same applies to the packing operations. This makes it easy to control your robots in a reactive, precise and relevant way ! We also have the solution for multi-product loading …

Request for a quoteResults for

Loading robots - Import exportNumber of results

30 ProductsCountries

Company type

Category

- Industrial robots (7)

- Assembly robots (4)

- Unloading and loading ramps (4)

- Welding robots (4)

- Automation - systems and equipment (3)

- Metals - Machines & Equipment (3)

- Cleaning machines, industrial (2)

- Mechanical engineering - custom work (2)

- Balancing machines and systems (1)

- Battery chargers (1)

- Brakes, servo-brakes and accessories (1)

- Fastening devices - machines for production (1)

- Industrial washing facilities (1)

- Insulating panels, asbestos-free (1)

- Internal transport systems (1)

- Robotics (1)

- Screw cutting - steels and metals (1)

- Software for industry (1)