- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machines with rotary tables

Results for

Machines with rotary tables - Import export

HIRSCH KOVIFLEX D.O.O.

Slovenia

Milling on a 5-axis machine with product dimensions: X=7100mm Y=2400mm Z=1500mm within tolerance of +/-0.02mm. Products are measured using a 3D measuring probe. Machining simulations are done in MasterCam program. We process various materials such as aluminum, steel, and plastic. Milling on 3-axis machines with product dimensions: X=2000mm Y=1000mm Z=550mm within tolerance of +/-0.01mm. Product control is done via Ranishaw measuring system. The system allows for quick control, precise adjustment, and, above all, high quality. Milling on a horizontal milling-boring machine with product dimensions: X=2810mm Y=1920mm Z=2000mm within tolerance of +/-0.02mm. Processing combines milling and drilling on a machine with a rotary table measuring 1800x2000mm and a load capacity of 10 tons.

Request for a quote

ERLO GROUP

Turkey

Transfer machines allow to perform different machining processes of parts or components within the same solution. Our solutions can be designed according to customer demands enabling processes such as drilling, turning, milling, tapping, countersinking, internal and external grooving and reaming among many for more than one product on a single CNC machine.

Request for a quote

FERPLAST SNC

Italy

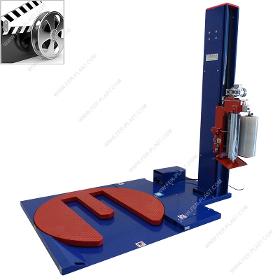

Wrapping Machine Mod. FP 15 SE/T with table cut for loading and unloading with pallet, and safety photocell, photocell height sensing pallet, digital panel with 3 programs winding, inverter for soft start, manual lock/cut of the film and automatic wrapping cycle (machine CE). NOTE: the machine is loaded from the side. When ordering, with a surcharge, it is possible to obtain the modification for the front load. UPON REQUEST WE CAN MAKE WITH WRAPPING MACHINES: Rotary table diameter mm. 1800 (pallets up to 1300x1300 mm)Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button. The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine with rotary indexing table and tool magazine. Automatic tool changer with HSK spindle tools. Mosts common tools used are tampico and sisal fibre brushes for bottom, bottom radius and side wall polishing.

Request for a quote

FERPLAST SNC

Italy

Place the pallet on the platform, attach the film to the base, select the wrapping program and press the start button.The machine automatically winding and stops. Cut the film manually. On requrest we can produce wrapping machines with: Rotary table diameter mm. 1800 - 2000 Electronic balance with load cells Load/ Unload rollers STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

High-precision absolute angle encoder with flat design with integral bearing Magnetic operating principle therefore extremely insensitive Perfectly suited for applications in CNC machine tools such as rotary tables Serial interfaces for Siemens and Fanuc. Siemens version with Functional Safety certification.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Highly accurate absolute angle measuring system with flat design and integrated bearing. Magnetic operating principle therefore extremely insensitive Perfectly suited for applications in CNC machine tools such as rotary tables. With serial interfaces for Fanuc, Mitsubishi and Yaskawa CNC available.

Request for a quote

FERPLAST SNC

Italy

Place the pallet on the platform and hook the stretch film to the base then press the start button. The platform begins to rotate, after 2-3 turns operate the button for coil ascent. After reaching the desired height, stop the lifting of the reel and after 2-3 turns stop the machine or operate the descent of the reel and carry out the winding up to the base of the pallet. At the end of wrapping, press the stop button and cut the film. On request we can produce wrapping machines with: Rotary table diameter mm. 1800 - 2000 Electronic scale integrated STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Do you have individual requirements for your laser processing center that our standard laser system of the LS series cannot meet? We develop together with our customers from stand-alone systems to integration into existing lines. In doing so, system know-how meets automation and laser technology: - robot solutions - portal variants - rotary table machines - sliding table systems - scanner solutions - integrated solutions based on VARIOMODUL® or, - at your request, on standard laser machines of the LS series For further information please take a look at our homepage.

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

It is a type of sandblasting machine in which the placed parts are sandblasted with the rotation of the horizontally positioned circular table. It is preferred for sandblasting medium-sized parts that are not suitable for hanging.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The C 650 uses a modification of HERMLE's tried-and-tested gantry-type design, with a mineral-cast machine bed. The integrated, rigid clamping table can cope with workpieces up to a maximum of 3000 kg (1050 x 900 x 600 mm) in the 3-axis version, making it ideal for toolmaking, mould construction and machine construction. The swivelling rotary table of the 5-axis version can accommodate workpieces up to 1500 kg (Ø 900 x 600 mm), allowing for highly precise machining. The traverse path in the stainless-steel-clad working area comprises 1050 x 900 x 600 mm with a vertical table clearance of 775 mm and a door aperture of 1050 mm. Ideal parameters for simple and safe crane charging. The C 650 has an integrated tool magazine for 42 tools. The control panel of the C 650 is also designed to swivel easily to the magazine loading location, so the operator can enter the tool data directly into the tool table in the control system.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Ultra Compact Rotary Table No table face for direct connection to trunnion setups High speed and accuracy Rotary joint as an option *R Kitagawa CK series is a Ultra compact body for small footprint machines, trunnions can be directly mounted to table spindle keeping overall setups very compact. Available with all motor types in right or left hand configurations to suit a variety of machine models. Price includes Rotary Table, Motor to suit (Fanuc, Mitsubishi or Yaskawa) and cables internal and external(subject to machine model). The CKR comes with rotary joint to suit hydraulics or pneumatics. RAV specification comes with an external controller that functions off a spare M-Code; used for machines that do not have 4th axis preperation.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Greatly expand the capability of your EDM machine Stainless steel construction Sealed and fully submersible Light weight and compact The DM series of rotary tables are completely waterproof and are designed for EDM applications. They are built from stainless steel and can be completely submerged. The DME100 table has an a Fanuc absolute encoder to improve precision and is only available as a 4th axis. The DM100 is available with a Kitagawa controller or with a suitable motor to interface with a machine that has already been prepared for an additional rotary axis. Both rotary tables are compact and high precision and will greatly expand the capability of a spark or wire erosion machine. These rotary tables are available with specially designed submersible chucks and tailstocks. RAV specification comes with an external controller that functions off a spare M-Code; used for machines that do not have 4th axis preperation.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Rotary table machines are used for applications that involve production of large counts in cycle time-optimized manner. The machine design allows for dividing the application into several process steps. The number of operating stations depends on the respective task. The individual operating steps are performed in the different stations within the work space simultaneously with loading in the loading area. Indexed tool change is optionally possible.

Request for a quote

KLN ULTRASCHALL AG

Germany

We work with you to develop the best possible solution for your project based on standard systems or modular functional modules. We have developed solutions for welding, punching, riveting, drilling, wrapping, flanging, handling and many other processes. Your task is most important for us and our technicians will try find together with you a solution meeting the requirements in quality, cycle time and cost. Examples of special systems: • final processing machines for plastic fuel tanks • rotary table machines for vibration welding, infrared welding, ultrasonic welding and hot plate welding • edge-welding machines for textile back injection molded parts • ultrasonic or mechanical punching machines • infrared welding machines in modular design for welding of several parts in one go • fully automated operating cells e. g. with feeding technology and robot handling

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The TNC 620 is compact and easy to read. The TNC 620 is a compact but versatile contouring control for up to five controlled axes. Thanks to its flexible operating concept—workshop-oriented programmability with HEIDENHAIN conversational programming or offl ine programming—and its scope of features, it is especially suited for use on universal milling, drilling and boring machines for the following: Series and single-part production Toolmaking Machine building Research and development Prototypes and pilot plants Repair departments Training and education facilities And it offers the applicable features both necessary and helpful: Universal milling machines Free contour programming Milling cycles for complex contours Fast presetting with HEIDENHAIN touch probes Drilling and boring machines Cycles for drilling, boring and spindle alignment Cycles for linear and circular point patterns Five-axis machining with swivel head and rotary table

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

This model is well suited for efficient, economical processing of circular workpieces via surface and step grinding operations. There is no lost time through deceleration, acceleration and reversal as with conventional reciprocation grinding. The grinding wheel remains in contact with the workpiece throughout the grinding process. Single workpieces can be located centrically on the table while multiple workpieces can be located concetrically to optimize table space utilization. A tilting table option allows grinding of chamfers or blade edges (i.e. circular blades), where the table can be tilted +/- 5 degrees. The high-precision rotary table is belt driven. This machine is offered with the xpressCube SPS controls package. A software option is available for step grinding operations. Benefit Overview — Compact and robust machine design — High productivity through continuous contact between wheel and workpiece — High long-term precision — Precision rotary table — Easy to operate

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The Vertical Rotary Table Grinder Model TRIREX is a modular designed machine. The Vertical Rotary Table Grinder has a bigger vertical stroke, which allow the machine to process the required working envelope. The Vertical Rotary Table Grinder consists of well proved modules. A long-term experience in the field of grinding with special machines guarantees the actual grinding technology. Important points include : Control (Siemens or Fanuc) Up to 5 axes CNC grinding center Optional with turning and measuring option High preassure deburring Up to 4 spindles possible Grinding capacities from 7,5 - 60 kW Dressing spindle next to the rotary table Tool changer Work piece Loading Zero point clamping system

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

Multitasking machines for combined, precise milling, turning, and grinding of complex workpieces. Unique ergonomics and user-friendliness for optimum operation and work processes thanks to low machine table with integrated vertical rotary table and open access to the work area. Optimal machine concept for the production of single workpieces and series production. - Machining of complex workpieces in one clamping operation Longitudinal (X): 2,500 – 4,000 mm Vertical (Z): 1,250 – 1,800 mm Cross (Y): 1,200 – 1,500 mm NC-rotary table: Ø 1,250 – 2,000 mm

Request for a quote

EMSIL TECHTRANS SRL

Romania

displaceable rotary tables are intended for increasing the technological possibilities of the horizontal boring and milling machines with moving column

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

FERPLAST SNC

Italy

Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button.The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet. STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

High clamping torque, high accuracy and high rigidity, Kitagawa NC Rotary Tables feature proven technology. The use of rotary tables allows the benefits of one-hit machining to be exploited to the full. Through this process, most - if not all - metal cutting requirements are undertaken by a single machining centre, irrespective of component complexity. The advantages of such a technique are clear. They include: only one machine set-up; one fixturing set-up; cost and time savings associated with reduced parts handling; and the elimination of tolerance errors accumulated as workpieces are moved from machine to machine.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

This mobile table has been produced for the purposes of packaging sterilized products, examining surgical instruments, etc. The mobile desk includes a mobile essential element, a heightadjustable desk. • Mobile table with four wheels, two of which have brakes, the size and height of which the device and the front table can be easily adjusted by the user. • This table is stainless oven painted and its top is AISI 304 stainless steel. • It has hook system on the sides for attaching two 1 STU autoclave baskets when required (optional). • Its dimensions are suitable for all sealers and also for A055 Stand (except for rotary sealers with printer and Automatic Pouch Makers). • Check out our wide and drawer table suitable for Automatic Pouch MakersA090 • Check out our narrow mobile table suitable for other closing devices A080

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

This mobile table has been produced for the purposes of packaging sterilized products, examining surgical instruments, etc. The mobile desk includes a mobile essential element, a heightadjustable desk. • Mobile table with four wheels, two of which have brakes, the size and height of which the device and the front table can be easily adjusted by the user. • This table is stainless oven painted and its top is AISI 304 stainless steel. • It has hook system on the sides for attaching two 1 STU autoclave baskets when required (optional). • Its dimensions are suitable for all sealers and also for A050 Stand (except for rotary sealers with printer and Automatic Pouch Makers). • Check out our large mobile desk suitable for rotary sealers with printer A085 • Check out our wide and drawer table suitable for Automatic Pouch MakersA090

Request for a quote

IMOBERDORF AG

Switzerland

Watch movements are among the most complex, most precise and most elaborate mechanical objects that can be produced. Since the development of the first rotary transfer machine for watch components in 1953, Imoberdorf has always pursued the goal of constructing systems that set new benchmarks with regard to productivity, flexibility and precision - and that are compact in construction and design at the same time. This enables boards, crowns and other watch parts to be manufactured with high precision, flexibility and in large quantities. Your quality standard is our trademark.

Request for a quoteResults for

Machines with rotary tables - Import exportNumber of results

27 ProductsCountries

Category

- Packing and packaging - machinery and equipment (4)

- Hydraulic equipment (2)

- Machine tools - metal machining (2)

- Precision measuring instruments (2)

- Sealing and wrapping - machinery and equipment (2)

- Adjustment - machine tools (1)

- Automation - systems and equipment (1)

- Bottling and filling - machinery and equipment (1)

- Construction - Machines & Equipment (1)

- Drilling services (1)

- Gears (1)

- Mechanical engineering - custom work (1)

- Metals - Machines & Equipment (1)

- Milling - machine tools (1)

- Milling - steels and metals (1)

- Numerical control systems - minicomputers and mainframes (1)

- Polishing - machine tools (1)

- Sandblasting equipment (1)

- Shaping - steels and metals (1)

- Turbines (1)