- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drying machinery and equipment

Results for

Drying machinery and equipment - Import export

FRIGORTEC GMBH

Germany

The POWDRYER™ PD08 metal powder dryer is used to dry inorganic metal powder for the complex additive manufacturing (3D printing) process. It corrects the manufacturer’s fluctuating metal powder qualities, thus optimizing the metal powder’s flowability. It also reduces the number of air inclusions in finished workpieces. Significantly higher material densities are the result. Fields of application > Particularly for metal printing products where maximum strength is required > For the printing of alloys of aluminium, titanium, tool steel, etc. > Special tools for the metal-processing industry, machine and system engineering, prototype development, and more > Aviation, aerospace, and automotive industries, plus medical and dental technology

Request for a quote

DC PRODUCTS

United Kingdom

Finish: Light grey Seven auto programmes; four timed programmes Sensor-controlled auto programmes stop drying when clothes are dry Dryer can be mounted on washing machine LCD display and interface on local language (13 languages) Reversible door (right/left) Manual or automatic drainage of condensation water – drain hose included Stacking brackets for column installation included Connection: 230V / 1ph / 13A / 50Hz / Max effect: 2.8kW Can be reconfigured to: 230V / 1ph / 10A / 50Hz / Max effect: 2.25kW Condenser dryer

Request for a quote

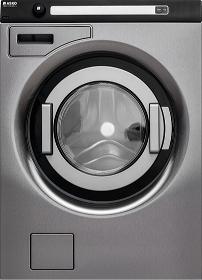

DC PRODUCTS

United Kingdom

Maximum spin speed: 1400rpm Finish: Touch Proof™ Stainless steel 28 programmes including three custom programmes Relay card for auto dosing with three signals Anti-leakage system and child lock ECO cold and hot water connection – saves up to 70% of electrical consumption and 20% of the programme time Connection: 230V / 1ph / 16A / 50Hz / Max effect: 3.2kW Can be reconfigured to: 230V / 1ph / 10A / 50Hz / Max effect: 2.2kW or 400V / 3ph / 10A / 50Hz / Max effect: 3.2kW Available with pump or valve drain system

Request for a quote

DC PRODUCTS

United Kingdom

Maximum spin speed: 1400rpm Finish: Light grey 28 programmes including three custom programmes Anti-leakage system and child lock ECO cold and hot water connection – saves up to 70% of electrical consumption and 20% of the programme time Connection: 400V / 3ph / 16A / 50Hz / Max effect: 4.6kW Can be reconfigured to: 230V / 1ph / 13A / 50Hz / Max effect: 2.4kW Available with pump or valve drain system

Request for a quote

TURKEYRAF

Turkey

Maximizes heat transfer with D Form aluminum pipe winding, provides extraordinary performance with 71mm insulation thickness. Dust-proof condenser does not require maintenance, it is long-lasting thanks to its aluminum frame and electrostatic powder painted and galvanized coated inner and outer body. Apple Series with its negative (Static), positive (dynamic) or dual regime options and large volume, provides minimum energy consumption. Apple is suitable for installation types such as singular, block and land, and allows you to create different layouts in the Market.

Request for a quote

KORENSA IMPORT & EXPORT

Turkey

Our product is made of Virgin Polyethylene. This product has a straight cut perforated and shoulder cut perforated these can be easily broken and also has a 9 cm ventilation hole. It is produced as printed or unprinted 20 kg rolls. The thickness, width and length of our product vary according to the customer’s demand. It can be produced suitable for all kinds of textile products.

Request for a quote

SUPREMA DRY CLEANING 100% MADE IN ITALY

Italy

Most advanced ecological & environmental friendly machine fully automatic & pneumatic operation, Loading door 500 mm for easy loading Ecological friendly – no external contamination solvent containment, filling, discharge and venting are completely sealed Adjustable Solvent Level with Computer closed circuit with heat pump compressor Freon R407a LOW NOISE – Scroll technology - Advanced super fast & efficient drying circuit Fridge gauges and pressostat group (High & low pressure) , with safety valve, soundproof compressor Advanced super fast & efficient drying circuit with automatic electronic temperature adjustment self cleaning fully automatic tank with frontal windows + S.S. insert Distillation Unit in stainless steel with internal inspection light & service hatch Ergonomic shape for faster distillation and avoid overflow – fully hermetic pressurized distillator Continuous OR fractional distillation

Request for a quote

MIRAI INTEX

Czech Rep.

MIRAI Cold 80 T operates in a closed cycle as an indirect refrigeration system with Air as a refrigerant. The machine comes with a factory-equipped heat exchanger which is optimized to work with silicone oil (also compatible with other working fluids). The system is a standalone unit that requires minimum servicing and maintenance.

Request for a quote

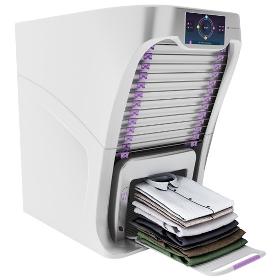

FOLDIMATE

United States

INPUT - FoldiMate will fold and treat most of your laundry (e.g. shirts, pants, towels). Except for large items like linen or small items like underwear or socks. Clip Capacity: ~15-20 items depending on size and feeding speed OUTPUT - Tray Capacity: 10-30 items depending on fabric thickness Output Size: 9”x11” (~23cm x 28cm); automatically adjustable Folding Method*: We start with a neat, professionally looking fold (* More methods will be available via FoldiMate’s “internet store”) SPEED - Clipping: Under 5 seconds Folding: ~10 seconds per item De-Wrinkling: ~20-30 seconds per item TREATMENT (Optional) Steam: Reduce wrinkles Capsules: Perfume, softening, sanitization DIMENSIONS - Size (WxHxD)*: 28”x32”x31” - 71cm x 81cm x 79cm (* Average dryer/washer) Weight: ~66 pound (30kg) Power: Standard 110v / 220v Wifi: Internet enabled Price: ~$700-$850 Steam: ~$200-$300 Capsules: ~$15-$40 Pre-Orders*: ~12-18 months (* Starting with paid reservations)

Request for a quote

SAMARIT CZ S.R.O.

Czech Rep.

-Spring-mounted base drops as the trolley is loaded and lifts as unloaded. -Side walls and bottom are ftted with plastic. -Polyurethane protectors shield the construction itself and other items from -damaging if bumped. -Work load – max 40kg. -Weight of the product – 41 kg. -External dimensions (W*D*H): 885*635*902mm -Finishing external – Galvanic zinc. Тhe trolley is equipped with: -polyurethane crash protectors (4pcs) -castors Ø100mm (4 pcs – swivel) Contact us to check possible dimensions and other options.

Request for a quote

SAMARIT CZ S.R.O.

Czech Rep.

-Mobile and compacted trolley. -Suitable for light weighted loads of linen. -Trolley can be folded that allows to save space while storing and transporting. -All castors are swivel (ø 75mm). -Work load – max 40kg. -Weight of the product: 6kg. -External dimensions (W*D*H): 590*420*680mm. -Finishing external: Galvanic zinc. -Product code: 11.1350.5 Contact us to check possible dimensions and get more information.

Request for a quote

SAMARIT CZ S.R.O.

Czech Rep.

-Walls are made of round tube. -Doors: upper one is hinged, lower one – is turning, opens aside together with upper door. Height of each door is 632 mm. -Horizontal bars on the sidewalls, back wall and doors are made of the flat bar. It adds more hardness to the container. -Container is entirely meshed that allows automated wash. -Work load: 270kg. -Weight of the product – 35 kg. -External dimensions (W*D*H): 710*800*1620mm -Mesh size:150*450mm. -Finishing external: Galvanic zinc. Тhe container is equipped with: -metal pocket/plate -plastic panel for meshed bottom -castors Ø125mm (2 pcs – swivel, 2 pcs – fixed) Additional options: -foot kip -swivel castors with break -magnet plate -branded sticker Contact us to check possible dimensions and other options.

Request for a quote

SAMARIT CZ S.R.O.

Czech Rep.

-Container is made of square tube. -Roll container is completed with folding door and front sidewall. -Height of the folding door – 648 mm, height of the bottom door – 648 mm. -Opened folding door doesn’t affect the dimensions of container, which allows exploitation of roll container in small areas. -When doors are closed, container becomes four-sided. -Small dimensions of a bottom door contribute to convenient and quick front loading of linen to roll container. -Work load – max 250kg. -Weight of the product – 37 kg. -External dimensions (W*D*H): 710*800*1620mm -Mesh size:150*450mm. -Finishing external – Galvanic zinc. Тhe container is equipped with: -metal pocket / plate -plastic panel for meshed bottom -rubber wheels of a good quality with roller bearing Ø125mm (2 pcs – swivel, 2 pcs – fixed) Additional options: -foot kip -swivel castors with break -magnet plate -branded sticker

Request for a quote

SAMARIT CZ S.R.O.

Czech Rep.

-Roll container with two doors that open aside. Widely-spaced grid makes weight the roll container lighter. -This roll cage is fitted with two shelves. Shelves can be easily folded vertically onto the side wall, creating integrated loading space inside roll container. -Shelves can be demounted when required. -Work load – max 250 kg. -Weight of the product – 37 kg. -External dimensions (W*D*H): 810*590*1700mm. -Mesh size:113*370mm. -Finishing external – Galvanic zinc. Тhe container is equipped with: -metal pocket/plate -plastic panel for meshed bottom -castors Ø125mm (2 pcs – swivel, 2 pcs – fixed) Additional options: -removable shelves -foot kip -swivel castors with break -magnet plate -branded sticker Contact us to check possible dimensions and other options.

Request for a quote

SAMARIT CZ S.R.O.

Czech Rep.

-Roll container is made of round profile tube -Front side wall is demountable. When needed, doors can be demounted, that will make weight of roll container lighter. While moving a roll cage without doors, it is recommended to use rubber belts to secure the linen -Work load – max 250kg -Weight of the product – 37 kg. -External dimensions (W*D*H): 680*800*1560mm -Mesh size: 128*246mm -Finishing external – Galvanic zinc Тhe container is equipped with: -metal plate / pocket -plastic panel for meshed bottom -castors Ø125mm (2 pcs – swivel, 2 pcs – fixed) Additional options: -shelves -top -door that open aside -foot kip -rubber belts -swivel castors with break -magnet plate -branded sticker Contact us to check possible dimensions and other options.

Request for a quote

SAMARIT CZ S.R.O.

Czech Rep.

-Walls are made of round tube -Two doors that open aside -Due to the rubberized wheels with ball bearigs container moves softly without leaving any traces on the floor. Wheels are fitted with thread protection, which prevents thread spooling on the wheel axis -Construction has mesh base -Documents can be placed into the metal pocket and/or identification magnets can be put there -Work load – max 270 kg -Weight of the product – 36 kg -External dimensions (W*D*H): 680*800*1700mm -Mesh size:110*166mm -Finishing external – Galvanic zinc Тhe container is equipped with: -metal pocket/plate -plastic panel for meshed bottom -castors Ø125mm (2 pcs – swivel, 2 pcs – fixed) Additional options: -removable shelves -foot kip -swivel castors with break -magnet plate -branded sticker -cover Contact us to check possible dimensions and other options.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ROBINSON CO.

Turkey

It is used to separate heavy foreign materials such as stones, glass and metal pieces or soil pieces in the grain with the help of screening method and air. The machine consists of a fixed chassis and vibrating body. The stone separator, designed considering the difference in density of stone and grain, separates the stone by directing the grain in the direction of gravity, in the opposite direction of gravity, with the help of vibration. Wheat is separated from the stones with the help of a vibrating sieve. In addition, dust is absorbed by the air aspiration provided from the ventilation line. Apart from flour and semolina factories, it is also used in all grain factories, vegetable oil factories, cocoa and coffee processing plants.

Request for a quote

ROBINSON CO.

Turkey

Instantly measure and display of humidity and hectoliter of wheat Calculation of water flows according to the required humidity. Automatic water dosage according to the calculated water flow value Automatic water dosage according to the wheat flow variation by the connection of wheat flow control or measure unit Alarms of failure More than one humidity – hectoliter measuring unit and water the dosage unit can be controlled by the PLC control unit.

Request for a quote

ROBINSON CO.

Turkey

It is utilized as a part of the flour plants to isolate any outside material that might be blended into conclusive item amid processing procedure or capacity. The remote materials isolated from item before pressing, item stockpiling or mass stacking storehouse. FEATURES - MFDJ It is utilized as a part of the flour plants to isolate any outside material that might be blended into conclusive item amid processing procedure or capacity. The remote materials isolated from item before pressing, item stockpiling or mass stacking storehouse. - MFNM - Best machine in practice. - Most economic spare parts. - Long life. - Seperation of fat with intensive operation. - Nindamac helps to achive high aqualit diffrent granulation of finished product with low fat content. For high technology degermination done by Nindamac by the

Request for a quote

ROBINSON CO.

Turkey

While the grain is carried upwards with the anchors made of hard material resistant to abrasion formed in appropriate dimensions on the rotor in an angled semi-cylindrical body made of stainless steel, the water is absorbed by the grain by subjecting it to intensive mixing at a measured speed. It is used in grain processing plants to ensure that the desired moisture content of the grains penetrate and feed the grain sufficiently. It brings the grain to be annealed with water and provides a homogeneous mixture. At the same time, a significant amount of peeling is ensured in the grain shell as a result of friction caused by the rotor rotating at high speed. Application Fields ◾ At food industry ◾ At the dry cleaning units of the flour and semolina mills ◾ At the grain processing plants where moistening process is required

Request for a quote

ROBINSON CO.

Turkey

It is used for separating garbage, straw, ear, other coarse and small foreign matter from wheat and other whole grains. In the food industry; In flour and semolina factories, seed cleaning facilities, grain cleaning and calibration facilities, grain factories, feed mills, silo facilities. In other similar industrial facilities; Low power consumption, high efficiency and high capacity Easy and minimum maintenance, trouble-free operation thanks to vibro-motor drive, Possibility to reach maximum capacity and efficiency for various grains with adjustable sieve angle, Durability and longevity Quick and easy replacement of sieves, practical cleaning possibility Quiet working

Request for a quote

ROBINSON CO.

Turkey

Thanks to the belt-pulley mechanism driven by an electric motor, the rotational motion is transferred to the sieve shaft. The sieve weights, which are placed unbalanced, connected to the sieve shaft, make the sieve vibrate. The position of the screen weights can be adjusted around the screen shaft in order to change the vibration amplitude of the screen. The screen is hung on the ceiling of the place where it is located by means of composite rods in order to create the vibration comfortably. Thanks to this vibration movement, in specially designed sieve boxes, the incoming product is classified and sifted according to its grain size. The product to be screened is sent to the screening area through one or more inlet pipes. Various types of silk-covered cases allow separation in seven channels. This part is directed to the outlet by the channel. After the product is sifted, it is sent to the outlet pipe on the bottom plate. It also has sight pipes for product control and monitoring.

Request for a quote

ROBINSON CO.

Turkey

It is used for breaking and crushing wheat in flour factories. The most important machine of the flour mill, the roller mill consists of two pairs of roller balls operating in parallel. Unlike the pneumatic roller, the incoming product amount is measured with the help of a sensor or load cell. Feeding rollers change speed according to the incoming product amount and provide homogeneous flow. At the same time, the gap between the rolls is closed by pneumatic pistons and allows the product to be grinded by passing through the rolls. The bearings of the rolls are ductile iron and the arms of the rolls are conical. It is produced with gear drive and belt drive. It can also be produced with an optional touch control screen. Especially thanks to the side covers that can be opened one by one based on the opening system, it provides fast and easy access and the possibility of rapid ball removal with the cover opened on the ball.

Request for a quote

ROBINSON CO.

Turkey

By separating the flour particles adhered to and remaining in the bran, it both prevents the loss of flour and increases the efficiency. Thanks to the special pallets on the rotor that rotates horizontally, the flour is separated from the bran while being thrown towards the screen. The centrifugal directed product strikes the pore size preselected screen. Thus, it is ensured that the flour particles are directed to the outside of the sieve and the bran to the outlet channel from the inside. Applications Fields ◾ Flour Mills ◾ Semolina Mills

Request for a quote

ROBINSON CO.

Turkey

The Air Channel is used for cleaning wheat, barley, legumes and soybeans. The machine removes all kinds of light materials different from cereal grains in terms of aerodynamic properties: garbage, straw and spike fractures, various seeds, peeled shell and dust from the product by means of air flow. While the grain products are distributed homogeneously in the width of the Air Channel with the feeding table of the machine or a vibrating feeder, the light particles in it are conveyed to the upper outlet channel with the air flow coming from the bottom, and the cleaned product falls down and transferred into the system. ◾ The lighting created by the window enables the separation to be seen clearly and thus all kinds of air adjustments can be made. ◾ Manufactured in two types, this machine with vibro motor is usually used with a Peeler machine, the non-motorized one is used with a Garbage Purifier machine.

Request for a quote

ROBINSON CO.

Turkey

Bucket elevators are used to transport granular or powdered products with buckets attached to their belts from the bottom up. They are manufactured in various sizes and capacities according to the needs. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

This machine is utilised for blending of various sort of grain as asked for rates and conformity of limit before processing area or treating segment. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

Moving through the centre, the product is transported to a horizontally positioned blade rotor. During rotation, the product is pushed against the wall of the machine and the eggs, if any, are destroyed inside the machine.

Request for a quoteResults for

Drying machinery and equipment - Import exportNumber of results

159 ProductsCountries

Company type

Category

- Bakery - machinery and equipment (36)

- Bakery and confectionery industry - machinery and equipment (30)

- Pastry-making - machinery and equipment (19)

- Milking - machinery and equipment (18)

- Axles, vehicle (18)

- Flour milling - machinery and equipment (17)

- Laundry and dry cleaning machinery and equipment (15)

- Bakery - machinery and equipment (13)

- Food industry - machinery and equipment (13)

- Textile dyeing (9)

- Textile dyeing - machinery and equipment (9)

- Confectionery - machinery and equipment (8)

- Painting machinery and equipment (7)

- Mining and quarrying - machinery and equipment (5)

- Catering - machinery and equipment (5)

- Lubrication equipment and machinery (5)

- Packing and packaging - machinery and equipment (5)

- Bottling and filling - machinery and equipment (4)

- Brewing - machinery and equipment (4)

- Harvesting machinery and equipment (4)