- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- oxygen cutting - machines

Results for

Oxygen cutting - machines - Import export

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc Magicut is a cost effective cutting solution in its class. 1. Rigid structure, strong and precision grinding T-rail 2. Gas control system for Oxyfuel cutting up to 4 oxygen torches. 3. Durable sealed cable chain for X & Y Axes with better protection 4. Operator platform - Flip down chair design suitable for production and maximize operation space *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

High precision CNC cutting machine 1. Advanced CNC controller - high performance control system 2. High accuracy - ±0.1mm 3. Precision linear way with copper cover for durable lifetime 4. Rigid structure, strong and precision grinding I-rail. 5. Gas control system for Oxyfuel cutting 6. Cutting thickness max. 300mm 7. Durable sealed cable chain for X&Y axes with better protection 8. Applied industries - offshore wind power, steel structure industry, metal processing industry, etc. OPTION : 1. IHT automatic flame cutting torch 2. Plasma / oxyfuel bevel cutting 3. Tube cutting 4. Total cutting solution, includes: -Track foundation (H beam) -Fume extraction table -Dust collector 5. Nesting Software 6. Center drill device 7. LED lamp 8. Anti-spatter spray device *CE Conformity

Request for a quote

HTMACH - HT GRUP MAKINA A.S.

Turkey

Windows based CNC Unit Simple parts programmable feature Automatic torch height control Manual or Automatic cut selection Automatic air-conditioning and smoke extraction system Strong and high mechanical accuracy 0,1mm Torch protection system for any crash Axis positioning accuracy 0,02mm Axis positioning speed 30m./min. (max.) We produce; Plasma Cutting Machine Bevel Plasma Cutting Machine Plasma Pipe and Profile Cutting Machine Plasma Drilling and Cutting Machine Plasma-Oxy Cutting Machine with different dimensions of work tables. And we use also HYPERTHERM Technology and True Hole Technology. All of the components on the machine are world wide known brand names.

UNITED PROARC CORPORATION

Taiwan R.O.C.

Compact CNC cutting machine built for 100% duty cycle cutting operation. 1. Rugged and sturdy 2. Cutting effective 1200x1200mm / 1200x2400mm / 1500 x 3000mm 3. Available for both plasma and oxygen torch 4. Cutting table is suitable for both water and fume (two way use table) 5. Suitable for job shop looking to add their first piece of automated machinery 6. Easy for installation. *CE Conformity

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Oxygen Cutting is the most widely used industrial thermal cutting process. After the metal material is heated to the ignition temperature with high heat obtained by burning in oxygen, the heated part is cut with pure oxygen gas jet. As Ramazan Aycan Inc., we can perform oxygen cutting from 35 mm to 150 mm with our new generation CNC oxygen cutting machines.

Request for a quote

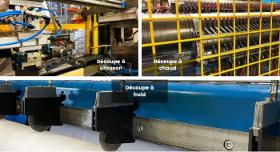

LOUISON INDUSTRIES

France

Industrial fabric cutting process Louison Industries offers custom cutting and cutting of textile fabrics produced by us. We offer made-to-measure industrial textile cutting for a wide variety of textiles. Whether for composite materials, reinforced technical fabrics or special textiles, our tailor-made approach guarantees professional-quality results that perfectly meet the specific needs of each project. Our industrial textile cutting skills encompass three main techniques: - Hot cutting - Cold cutting - Ultrasonic cutting We can produce a professional quality cut, adapted to the composition of the chosen textile, for all materials, small and large widths, from 10 to 1600 mm. The idea is to provide you with a finished product that can be used straight away.

Request for a quote

BIZERBA SE & CO. KG

Germany

Fully automatic slicer with integrated weighing technology for portioning and weighing of individual slices. With fully automatic product fixation. Easy to service and very robust – perfect for industrial use. Area of Use Robust slicer for industrial production

Request for a quote

EUROLASER GMBH

Germany

The cutting machine M-1600 offers laser cutting and engraving applications for the highest demands. With the optional eurolaser shuttle table system the productivity can be increased – offering a processing area of 1,330 mm x 1,630 mm (52.3" x 64.2"). This combination is ideal for applications like foils, acrylics, wood and textiles. The modular design enables eurolaser systems to be specially configured to suit every requirement. We analyze your requirements and configure the laser system individually for you. The usage of eurolaser laser machines enables you to process a wide range of materials, such as cutting of plastics, foams, textiles, adhesive foils, wood, acrylic, composite materials and much more. We are pleased to run a cutting test in our Application Center by using your individual material. Subsequently, you will receive a detailed test report in order to identify how your material was cut and engraved with our laser machines.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Guillotine for industrial hoses •up to 2” (max. OD: 75 mm) •Pneumatic Drive •L x W x H (mm) : 1810 x 325 x 800

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The EM 115 is a highly productive hose cutting machine. The machine is best suited for high volume manufacturing of 2" hoses along with workshop capability for 3" high pressure hose and 3" industrial hose. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

For each type of workshop: This cutting machine with its 3 kW drive is also available as an ecoline or DC variant. For hydraulic hoses up to 1 ¼”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This production cutting machine is available as a manual and as a pneumatic variant. Its cutting motors ensure optimum cutting results thanks to their unique minimum vibration. 4.6 kW drive. For hydraulic hose assemblies up to 2” and industrial hose assemblies up to 4”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The safe high-quality cutting machine for the production process. All cutting blades are made of carefully tested material which ensures optimum cutting quality. 7.5 kW drive max. For hydraulic hose assemblies up to 3” and industrial hose assemblies up to 4”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Planetary cutting machine for corrugated metal and PTFE hoses. Cutting results that often eliminate an additional step. This completely unique planetary cutting machine delivers almost scrap-free production and high efficiency. With a completely variable centering clamp system, all hose OD to the maximum rating for the machine can be cut. Approximate cutting time is 25 seconds for 1 ¼“ (ø DN 32). Productive and ergonomic •No dramatic flaring of the stainless steel braid •Reduces or eliminates time-consuming manual preparatory work thereby increasing productivity and lowering costs •Centering hose clamp system •Shortest cut possible from 10 cm •Minimizes personnel costs and preparatory work •No wrapping/unwrapping with adhesive tape required •Clearly laid-out user friendly software on a panel with a 6“ color display screen •Large article memory promotes productivity •Reference run for optimal positioning of the cutting blade for cutting all hose diameters CE compliant

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The small, light-weight cutting machine for workshops. 1-phase drive, 1.2 kW. For hydraulic hoses up to 1”. Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

For each type of workshop: This cutting machine with its 3 kW drive is also available as an ecoline or DC variant. For hydraulic hoses up to 2”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The new 2" 4SH + SAE R 15 hose cutting machine for workshops (also as a 3" industrial machine available). Designed to perfection. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZNER MASCHINENBAU GMBH

Germany

The special feature of the Metzner CCM 4: the circular cutting machine handles both wet and dry cutting. Depending on the type of cut, the CCM 4 is equipped with a water-cooling lubrication system or micro-knife moistening and preparation for suction. The standard model comes with an integrated discharge conveyor (800 mm length); application range both in-line and off-line. For tubes with suitable material properties the CCM 4 Gasket offers the possibility to cut flat gaskets with the circular knife. Suitable for tubes with max. 30 or 50 mm diameter and a tube length of 1 mm to 1000 m.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The Metzner CCM 2 circular cutting machine processes steel-reinforced profiles and sponge rubber materials with dry cutting (optionally with micro-knife moistening to cool the circular knife). The standard model comes with an integrated discharge conveyor (1300 mm length); range of application both in-line and off-line.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

The Ocut series provides unmatched performance, reliability, and flexibility in thermal cutting production environment. 1.Cutting diameter from 50~900mm 2.Working length 6000mm or 12,000mm 3.Support straight or bevel plasma cutting. 4.Rotation with self centering pipe fixture. 5.Height adjustable rotator. Save/Load each job's rotator height. 6.High torque drive system. 7.Dustproof high precision linear guide ways. 8.Self-aligned plasma torch collision holder. *CE Conformity

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed the mandrel cutting machines of the SR series for cutting off sealing rings from injection-moulded or extruded tubes with different diameters. These machines are characterised by their unique processing method and high cutting quality. First, pre-extended "rubber tubes" are clamped onto mandrels. Due to the special design of the mandrels, the mandrel can be set up and removed quickly and without special previous knowledge. The mandrels are then automatically clamped in the machine between rotating spindles and production is started. A knife carriage travels along the tubes and cuts the flat sealing rings to the desired length with either push-fit or circular knives, depending on the requirements. This cutting method is particularly impressive with its high cutting quality in combination with a high output.

Request for a quote

MAHERAS LTD.

Bulgaria

We have Plasma cutting machine. We can cut details from all kinds of steel.

Request for a quote

APERTE, UAB

Lithuania

Dimensions range: Maximal - 9000 x 3210, Thickness range - 2 - 19, Notes: Dimensional tolerances - ±0,5 mm

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

High precision CNC cutting machine 1. Advanced CNC controller - high performance control system 2. High accuracy - ±0.1mm 3. Precision linear way with copper cover for durable lifetime 4. Rigid structure, strong and precision grinding I-rail. 5. Gas control system for Oxyfuel cutting 6. Cutting thickness max. 300mm 7. Durable sealed cable chain for X&Y axes with better protection 8. Applied industries - offshore wind power, steel structure industry, metal processing industry, etc. OPTION : 1. Hypertherm / Kjellberg plasma power source 2. Bevel cutting 3. Oxyfuel cutting torch 4. Tube cutting 5. Total cutting solution, includes: -Track foundation (H beam) -Fume extraction table -Dust collector 6.Nesting Software 7.Center drill device 8.LED lamp 9.Anti-spatter spray device *CE Conformity

Request for a quote

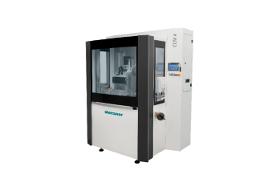

FINEPART SWEDEN AB

Sweden

High Speed Complex Precision 5 Axis Waterjet Cutting Technology, Ideal For Prototyping Ideal for prototyping or one-off parts and cutting highly complex shapes, with cutting width down to 0.2 mm. 5-axis cutting with tool center point control and corner optimization by waterjet motion strategy. Cutting width down to 0.2 mm 3 dimensional cutting 5-axis cutting with tool center point control High inclination angles and complex shapes Perfect for prototyping FINECUT MICRO ABRASIVE WATERJET TECHNOLOGY Advantages and Capabilities Increase Your Productivity, Cutting Speed, Precision, While Doing Complex Cutting. Ideal for prototyping Ideal for applications that require complex cutting 3D abrasive cutting capabilities Cutting 2X as fast, compared to 3 axis cutting Ultimate taper control and taper elimination Able to cut materials of almost any kind, both soft and hard materials

Request for a quote

FINEPART SWEDEN AB

Sweden

Finecut 3-Axis Waterjet Machine, a Premium Micro Abrasive Waterjet, Beyond Cutting Edge. Cutting width down to 0.2 mm Designed for ultimate precision cutting Highly dynamic and fully encapsulated motion system Flexible fixtures for different applications Intuitive HMI Easy set-up. Easy to operate. Easy to service. Ultra-High Precision Water Jet Cutting Machine – with Finecut™ WMC 500 II Waterjet Machining Center … BEYOND CUTTING EDGE Micro Abrasive Waterjet technology is the proprietary cutting system of Finepart. It was developed to accompany the Finecut Waterjet Machining Center and together they bring the waterjet technology to a whole new level of precision cutting. The micro abrasive waterjet process is a particle erosion based, non-thermal cutting process. This process can cut virtually all materials and produce an excellent surface finish that does not change the material properties.

Request for a quote

MVD MACHINERY

Turkey

P-Series Plasma machines are used for cutting thick metals, It is a reliable and robust plasma source. Hypertherm cutting head, CNC control unit and power source provides precise and high quality cutting. P-Series Plasma machines are designed for precision cutting, High Performance, High Speed It can be equipped with Pipe cutting, 5 axes beveling head, multi plasma heads and Oxy cutting heads.

Request for a quote

FINEPART SWEDEN AB

Sweden

Finecut 5-axis waterjet cutting machine is a premium micro abrasive waterjet, for fast cutting without taper. Ideal for volume manufacturing purposes Ideal for cutting complex shapes Cutting width down to 0.2 mm 5-axis cutting with tool center point control Corner optimization by waterjet motion strategy Compared to traditional cutting methods, the 5 axis waterjet technology has the cutting edge capabilities of combining increased cutting speed, ultra high precision, and three dimensional cutting, with taper elimination, into ONE cutting edge waterjet machine, the Finecut WMC500II Ideal for volume manufacturing purposes Cutting twice as fast, compared to 3 axis cutting Ideal for applications that requires complex cutting 3D abrasive cutting capabilities Ultimate taper control and taper elimination Able to cut materials both soft and hard materials

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

Being the smallest model of the new Q series, the Q 1500 achieves precise plasma cuts at the highest level for material thicknesses of up to 60 mm and with a maximum cutting current of 150 A. New components and especially the operator interface Q-Desk meet the complex requirements of a digitalised production in the age of Industry 4.0. The specially developed browser-based operator interface Q-Desk provides real-time process data and information of all plant components on any standard device and location-independent. The user benefits from extensive information enabling him to plan and execute a variety of maintenance tasks as guided by the system. This generation of plasma cutting systems is the result of intensive research and development work by Kjellberg and a landmark in the 60 years of Kjellberg's plasma history. The new digital plasma series Q sets pioneering standards regarding quality and connectivity.

Request for a quoteResults for

Oxygen cutting - machines - Import exportNumber of results

33 ProductsCountries

Company type