- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tig welding

Results for

Tig welding - Import export

COPIER MACHINERY

Netherlands

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

COPIER MACHINERY

Netherlands

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

ESTIMET SP Z O.O.

Poland

Our company specializes in a wide range of welding services, with an emphasis on high quality welding welds. We use modern technologies that guarantee excellent results. We carry out welding of a variety of materials, including carbon/structural steel, stainless steel and aluminum. Our production facility meets stringent quality standards, such as PN-EN ISO 3834-2:2007 and PN-EN 1090-2:2018-09. We have implemented modern welding technology for group 1.1 and 1.2 carbon steels in accordance with PN-EN ISO 15614-1:2017-08. Our skills include working with steels such as S355J2 and steels with lower yield strengths, especially for material thicknesses above 3 mm for fillet welds (3-23 for butt welds), welded using the MAG-135 method. We provide professional execution of any steel welding service.

Request for a quote

ESTIMET SP Z O.O.

Poland

In our production plant, we have implemented the technology of welding carbon steels from material groups 1.1 and 1.2. These are S355 J2 steels and steels with lower yield strengths. Range of thickness of welded materials: Butt welds are implemented for steel with a thickness of 3 - 24 mm Fillet welds are implemented for steel> 3 mm thick The welding method is MAG - 135, i.e. solid wire welding.We also weld stainless steel using the TIG method. We have ISO 3834-2 and ISO EN 1090 certificate. We weld steel elements and light steel structures, also in serial quantities.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

Tungsten inert gas (TIG) welding offers many advantages over other fusion welding methods, such as the complete absence of spatter and low welding-fume emissions. Since TIG welding uses a non-consumable electrode, the process is ideal for welding so-called root passes or in forced positions due to the decoupling of current and welding consumables.

Request for a quote

ARPIAL - METALURGICA LIGEIRA LDA

Portugal

Mig/Mag Welding of produced parts

Request for a quote

ARPIAL - METALURGICA LIGEIRA LDA

Portugal

Tig Welding of produced parts produced

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We specialize in the production of stainless steel sheet metal components, meticulously crafted according to the specific requirements and drawings provided by our customers. Utilizing advanced techniques including laser cutting, CNC bending, robotic welding, and robotic grinding, we ensure the highest standards of quality and precision at a competitive price. Additionally, we offer surface treatment services such as pickling and phosphating through our trusted partners, guaranteeing a comprehensive solution for our clients' needs

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

Tig welding Mig welding Spot welding Robot/Robotic welding

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

Option for Manual lifting control / Digital control box 1. High frequency protected. 2. Machined "T" slots table with pilot and through hole. 3. High quality worm gear reducers for smooth operation and minimal backlash. 4. Free maintenance grounding system. 5. AD type adjustable table height option available. 6. Standard forward/reverse rotation and variable speed control. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. Capacities range from 1,000 to 6,000 kilograms. 2. For pipes or vessels rotation. 3. Metallic rollers bounded with polyurethane. 4. Quick, accurate roll centering adjustment. 5. High frequency protected. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

Option for black glass No. 9, 10 or 11

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

Intelligent manufacturing Full automation Custom design For TIG, MIG, Plasma or other welding process

Request for a quote

MAHERAS LTD.

Bulgaria

We have 10 TIG, MIG and ARC welding machines. Our welders are among the best in Bulgaria. We can weld everyone steel.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

PT-103 welding positioner with standard control box PT-104 welding positioner with digital control box Rotation speed A type: 0.3-4 rpm B type: 0.6-8 rpm C type: 0.8-12 rpm D type: 1-16 rpm 1. High frequency protected. 2. Machined "T" slots table with pilot and through hole. 3. High quality worm gear reducers for smooth operation and minimal backlash. 4. Free maintenance grounding system. *CE Conformity

Request for a quote

WORCESTER ENGINEERING

United Kingdom

We offer ZURICH certified Coded Welding Services as follows BS EN ISO 9606-1 : 2017 BS EN ISO 15614-1 : 2017 LEVEL 2 Our approval codings cover a wide range of applications within our target industries. We encourage enquiries for 'assembly & weld' opportunities. Our hygienic workshops offer a clean and efficient environment for multiple batch / jig work. We're happy to quote full job or just labour, free issue material. We have storage facilities and happy to discuss call off. We are happy to certify our workforce to any coding required to undertake customer requirements. Our coded welding staff are also placeable, providing cover for holidays, illness and staff shortages at your premises.

Do you sell or make similar products?

Sign up to europages and have your products listed

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Numerically-controlled hydraulic press brake, numerically-controlled hydraulic shearing machine, numerically-controlled machining centres, numerically-controlled lathes and milling machines, mortising machines, presses, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting workstation, paint booth, assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment, testing and programming workstations, etc. With our diverse range of facilities and modular covered areas, we can manufacture practically any type of installation or equipment, with unlimited space and technological expertise. Our multidisciplinary team of highly qualified specialists, combining long-standing experience with the technical skills of youth, guarantees the optimal operation of our equipment and the quality of the facilities delivered to you.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

In addition to being able to work on site in an emergency to diagnose an unexpected breakdown and repair your installation, we are equipped with: a comprehensive machine fleet (numerically-controlled machining centres, lathes and milling machines, mortising machine, press, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting station) meaning that we can manufacture products to measure and supply all your replacement and wear parts in an emergency an assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment and testing and programming stations, where mechanical and electrical assemblies and sub-assemblies can be produced urgently and with a high degree of flexibility

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Our metal work unit is equipped with all the equipment required to carry out the majority of operations related to the production and shaping of metal objects: mortising machine, press, drilling machines, rolling machines, semi-automatic welding stations and TIG/Plasma/Oxycutting workstations. Our vast range of metal work equipment and the adaptability of the workshop’s covered areas are ideal for performing almost every type of shaping.

Request for a quote

ATOM KARINCA LASER

Turkey

It can quickly weld stainless steel and mild steel materials even for high-volume orders. In addition to robotic welding, we professionally perform TIG welding for stainless steel and aluminum by our certified welding team. We provide different welding procedures, i.e. MIG, TIG and spot welding.

Request for a quote

MECALTEX MECANICA GERAL DE PRECISÃO LDA

Portugal

MIG, MAG and TIG welding for raw or pre-machined steel, aluminum and stainless steel structures

Request for a quote

MECALTEX MECANICA GERAL DE PRECISÃO LDA

Portugal

MIG, MAG and TIG welding for raw or pre-machined steel, aluminum and stainless steel structures

Request for a quote

SC PROFINOX SRL

Romania

Profinox provides stainless steel welding services of the highest quality. We perform various types of stainless steel welding TIG welding (or WIG welding), MIGMAG welding, MMA welding, orbital welding, electric welding, but also aluminium welding. The main aspect that made us nationally known and appreciated among our customers was and remains the quality of our welding. We have a team of professionals and we make sure that our stainless steel welding, aluminium welding and other welding services are, without exception, performed in accordance with safety and quality standards. Our vast experience gained in making the most demanding types of welds, such as those in the pharmaceutical industry, recommends us. If you need stainless steel welding services, feel free to request a quote or contact us for more information.

Request for a quote

TRIBUNAS & FIGUEIREDO, LDA

Portugal

Mig-Mag TIG Laser Welding of carbon steel, stainless steel and aluminum.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quote

EUROWIRE LDA

Portugal

Works with Mechanical and Laser Cutting Operations and Plate Bending, MIG and TIG Welding and Drilling)

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

Hai Tong focus on sheet metal parts and we are professional sheet metal bender in China, we develop various kinds of sheet metal boxes using blanking, bending, TIG welding, grinding, and powder coating, some sheet metal boxes can be waterproof with IP65.

Request for a quote

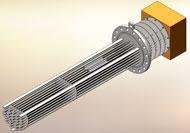

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electrical flange type immersion heaters The range of immersion heaters type FHK offers an economic heating solution for process tanks, pressure vessels and similar plant. The standard heater consists of a number of rod elements TIG welded into a process flange. A robust terminal box protects the electrical connections. The number of elements fitted depends upon the media to be heated and the kilowatt rating required. Dependent on application, the heater can be provided with temperature control by contactor or thyristor.

Request for a quoteResults for

Tig welding - Import exportNumber of results

97 ProductsCountries

Company type

Category

- Welding, electric - equipment and supplies (13)

- Welding, soldering and brazing - equipment and supplies (13)

- Welding work - steels and metal (12)

- Laser - cutting and welding machines (7)

- Steels and metals - welding and brazing (6)

- Steels and metals - forming and cutting (5)

- Autogenous welding machines (3)

- Milling - steels and metals (3)

- Motor mechanics - hand tools, non power (3)

- Industrial sheet metal work (2)

- Milling - machine tools (2)

- Sheet Metal & Tubes (2)

- Steel & Metals (2)

- Vacuum cleaners - industrial (2)

- Aluminium and aluminium alloys (1)

- Bending - steels and metals (1)

- Compactors and crushers (1)

- Dairies - machinery and equipment (1)

- Electron beam welding - equipment (1)

- Fencing - equipment and supplies (1)