- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- micro welding

Results for

Micro welding - Import export

ALPHA LASER GMBH

Germany

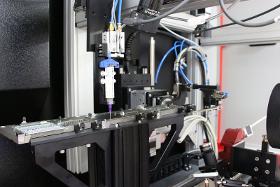

AL-SWS - the multifunctional laser workstation with variable table inserts for sensor production With this flexible laser machine you can effortlessly weld and cut even the smallest workpieces up to 12 mm in diameter, either automatically or manually. This laser system is mainly used in sensor production and in medical technology, for example for the production of jacket-insulated cables, sensors, resistance thermometers and thermocouples. Depending on the desired application, five different, interchangeable table inserts are available. These can be changed in a matter of seconds so that you can easily switch between the following welding or cutting tasks: Contact welding Circular welding Micro welding To cut Mantle welding under mechanical pressure

Request for a quote

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

Laser Micro-Welded Sub-Assemblies

Request for a quote

ALPHA LASER GMBH

Germany

The laser welding systems of the AL series can be used universally. They might be integrated into existing machine structures or used with an application device for manual welding. In combination with our NC-controlled laser machining table AL-T you get a real professional solution. We offer the required performance class for every application. You can choose between 75 and 900 W. There is a wide range of processing lenses and equipment options for these laser systems. Regardless of whether you use a simple 90 ° deflection lens, the tilt-swivel lens or our circular welding lens - the laser beam always reaches the desired point on the workpiece with pinpoint accuracy. Additional equipment options are optionally available for the AL, such as: • Micro welding device for a welding spot diameter <100 µm • Rotary axis module for cylindrical welds • automatic wire feeder • Workpiece holder • camera system •…and much more

Request for a quote

FORTIS M. BOROWY SP. J.

Poland

This version of welded mats consists of three layers: 0.3 mm PVC foil, printed paper and grey micro-rubber bottom, welded along the edges.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ORBITEC GMBH

Germany

Gas-cooled weld head for applications with extreme narrow space requirements as e.g. in the semiconductor industry. Specially designed to weld micro-fittings. Unique construction, including specifically directed gas routing to improve gas coverage and material selection resulting in a high duty cycle even without water cooling. — Extreme narrow / compact design — Simple design allows easy to maintain — Weld Head compatible with control element (start/stop kit with status display) — Arc Machines Model 9-500 cassettes will fit too

Request for a quote

MECHASYS GMBH

Germany

Laser welding is a very gentle welding technique, as the heat input takes place in a locally very limited area. In this way, it is possible to reliably connect critical components with one another in a materially bonded manner, without the parts annealing. With laser welding, the two welding partners are joined together with as few gaps as possible in order to then weld them together (e.g. press-fit zones such as EloPin® puzzled at any feed or distance). The background to this is that no additional material is generally used in laser welding. Exception for build-up welding or repair welding of e.g. broken tool parts such as punches or cutting plates or injection molding tools for abrasive plastics with glass fiber filling. Materials - almost all metals: e.g. • non-ferrous metals (Cu, CuSn0.15, CuSn6, CuNiSi, ...), • titanium, • steel, stainless steel (1.4301, 1.4404, ...), • spring steel (1.4310), • electrical steel (M235, M270, NO20, NO30, ...), …

Request for a quote

NANOSYSTEC GMBH

Germany

VersaHybrid is a semi or fully automated production system for complex assemblies which require a precision in the low micrometer regime. Assembly techniques include micro welding, selective laser soldering and gluing plus laser fine cutting. Various processing methods are combined in one station. Feeders, belts and robots allow for full automation.

Request for a quote

FOXLASER

Bulgaria

FoxLaser offers all types of welding of ferrous and non-ferrous metals: 7-axis robot cell for MIG/MAG welding. Positioner up to 5 tons. MIG/MAG – electric arc welding in a protective gas environment with a melting electrode. TIG – electric arc welding in a protective gas environment with a non-melting electrode and with automatic supply of additional material. TIG MICRO-WELDING with PUK-U3. MAW – manual metal (electric) arc welding. SPOT electric resistance welding. We have 3D welding tables for assembling complex sheet and tubular structures. Their dimensions are 3000/1500/200 mm and 2400/1200/200 mm. The use of special attachments and fixtures or the assembly of several tables together makes it possible to increase the size of the assembled structures.

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Highlights: The new B 20K high-performance welding control system combines all process, measurement and monitoring systems into one comprehensive system. Stepless welding frequency adjustment between 1,000 and 20,000 Hz guarantees a highly dynamic and even finer control compared to low-frequency technologies for even better resistance welding results. From micro to macro welding processes, from resistance soldering processes to heating processes such as annealing, the B 20K covers an immense range of applications. Furthermore, up to 18 servo axes for e.g. controlling contact welding equipment can also be used to integrate press applications and other options in the B 20K.

Request for a quoteResults for

Micro welding - Import exportNumber of results

11 ProductsCountries

Company type