- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pellet press

Results for

Pellet press - Import export

PARSMEGA MAKINA

Turkey

DISC DIAMETER is 660/520/420 mm. CHEWING WIDTH .228 mm TOTAL WIDTH .290 mm PALLETLING AREA .4727cm2 DISC WITH CONICAL RINK AND BOLT INTERNAL SPEED .6,9 m/secROLL DIAMETER .320 mm.ROLL WIDTH .232 mm DOUBLE ROLLER .BELT PULLEY TRANSMISSION and TWIN MOTOR 15* 15 TOTAL 30 PIECES V BELT DRIVEN MAIN MOTOR 2 PIECES 110 KV 1000 rpm .PELLET CELL 304 QUALITY STAINLESS STEEL PELLETIZING CELL SAFETY SWITCH .FIXED MAGNET .1 PIECE CHROME STEEL XT 86,day WITH DRILLING METHOD DRILLED VACUUM HARDENED AND TURNED-ISO 9002 QUALITY CERTIFIED PELLET PRESS DISC 1 SET COMPLETE ROLL.

Request for a quote

EQUILAB

Spain

The EQP-30 Manual Pellet Press can exert a pressure of up to 30 tons. It is a robust and durable unit, very easy to use. An hydraulic system multiplies the strenght applied by the user with the lever, and an analogical gauge shows the pressure tons reached. This press includes a safety system that automatically releases pressure above 30 tons. By using varied pressing tools, we can obtain pellets of different diameters.

Request for a quote

EQUILAB

Spain

The EQP-100 pellet press can exert a pressure of up to 40 tons, enjoying a robust and durable design. User-friendly, efficient, offering up to five working programs of single or double pressing cycle. Makes 40 mm pellets/tablets only. Very easy to manage, a comfortable display allows the user to digitally adjust the time and pressure. The double cycle pressing allows the release of occluded gases in the sample during the first cycle, ensuring thus the production of high quality pellets.

Request for a quote

EQUILAB

Spain

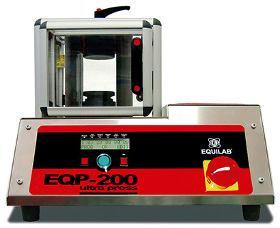

The EQP-200 Pellet Press has been especially designed to obtain high quality pellets/tablets for XRF. This press can exert a pressure of up to 40 tons. Of durable and robust design, it is very easy to manage, efficient, and offers 5 working programs with single and double pressing cycles. An exceptional instrument. Keeping all the features of its predecessor (EQP-100), the EQP-200 also offers the possibility of making pellets of different diameters, just by changing the pressing tool. This device facilitates also the cleaning and maintenance tasks. Its versatility enables the unit to work also with different shapes of press tools, such as square, rectangular, etc.

Request for a quote

EQUILAB

Spain

The EQP-1 Pellet Press can exert a pressure of up to 15 tons, it is very easy to use, and takes very little space. An hydraulic systems increases the strenght applied by the user with the lever and a and an analogical gauge shows the pressure tons reached. • High quality pellets in no time • User-friendly • Does not need electrical power • Analogical gauge • Compact and autonomous unit

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EMMALI HOLZ BV

Netherlands

A special developed, mechanical method modifies the surface structure of the straw and makes it especially absorbent. For this it is shredded, sieved an de-dusted before it gets pressed into pellets. During pelleting the straw is sterilised thermally. During this process the naturally occuring bacteria, yeast and mold are strongly reduced.

Request for a quote

EQUILAB

Spain

This small stirrer is your great ally to prepare a great variety of samples. Mixing liquids is usually required as the prior step to an analysis by ICP or AA. The homogenization of the solid samples with a binding agent is especially recommended for preparing pressed pellets, as well as the correct mixing up of the sample with borates that will later be melted using heat to obtain dissolutions or glass beads.

Request for a quote

EQUILAB

Spain

The great versatility of the new MultiEQP-100 makes of this unit an essencial instrument to treat and make metallic samples. Effective to cut, crush and punch metallic samples, it can also prepare press pellets to be analyzed by XRF. The objective of punching the samples is to obtain pins for their ulterior analysis in Elemental Analizers. The objective of the crushing is to achieve flat surfaces wide enough to undertake spark analysis. The touch-screen and the intuitive software enable the user to control easily the ample variety of operations the MultiEQP-100 features. The two magnetic sensors included in the left hand side of the working units allow the automation of all the working cycles.

Request for a quoteResults for

Pellet press - Import exportNumber of results

9 ProductsCountries

Company type