- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pur foam

Results for

Pur foam - Import export

ALUXFOIL - BAZIS GMBH

Hungary

18my aluminium / glass fibre fabric / PE composite foilThe polyethylene coating allows welding to the insulating material. For laminating on hard foam (PUR and PS) or on glass and rock wool, e.g. felt plates, pipe shells. steam-tight Sd-value > 1500 m heat-reflecting

Request for a quote

KURARAY (EVAL EUROPE N.V.)

Belgium

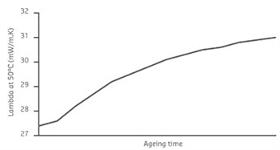

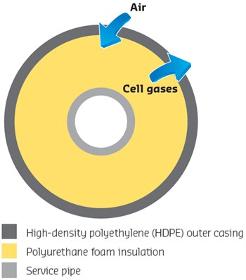

Decreasing insulation efficiency The insulation efficiency of PUR foam decreases over time as air permeates in and cell gasses permeate out of the pipe structure, increasing thermal conductivity. Oxygen permeation can also lead to oxidative degradation of the PUR-foam insulation itself. This reduces the adhesion between the PUR-foam and inner pipe, weakening the structure and compromising the mechanical integrity of the entire pipe system. Maintained efficency and improved performance with EVAL™ With EVAL™ the insulation efficiency of the PUR foam is maintained, avoiding an increase in thermal conductivity . Oxygen ingress that can degrade the PUR-foam insulation is also sharply reduced. EVAL™ provides good adhesion to the PUR-foam without additional surface treatement. For more information, please contact Cynthia Teniers

KURARAY (EVAL EUROPE N.V.)

Belgium

Many pre-insulated pipes use rigid polyurethane foam and a HDPE casing. Over time, the insulation efficiency of the pipe structure decreases, caused by the permeation of air (oxygen, nitrogen) into the foam cells and the diffusion of cell gases (blowing agent, carbondioxide) out of the foam cells. The insulation efficiency of PUR foam decreases as air permeates in and cell gasses permeate out of the pipe structure, increasing thermal conductivity. Oxygen permeation can also lead to oxidative degradation of the PUR-foam insulation itself. This reduces the adhesion between the PUR-foam and inner pipe, weakening the structure and compromising the mechanical integrity of the entire pipe system.

KURARAY (EVAL EUROPE N.V.)

Belgium

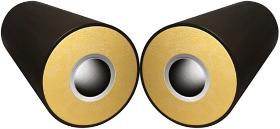

Pre-insulated pipes are incresingly popular for centralised and energy efficient district heating and cooling systems. Â A central service pipe is surrounded by PUR foam insulation and a durable HDPE outer cladding. Adding an EVALâ„¢ layer to the pipe structure helps extend system service life, by maintaining insulation efficiency and structural integrity. Â EVALâ„¢ helps make sure pre-insulated pipe systems performs not only longer, but more efficiently as well.

PANEL SELL GMBH

Germany

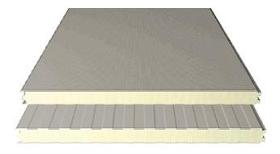

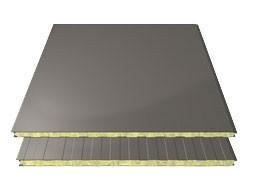

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

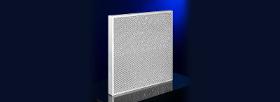

plane, compact design 4layer filter media coarse dust protective layer, 2 layers of activated carbon and abrasion protection layer at clean air side activated carbon layer of carbonimpregnated, reticulated PUR foam solid galvanised metal frame, with metal grids on both sides best combination of low pressure drop and adsorption capacities

Request for a quote

SSA PANA FOAMTEC

Serbia

PVC (polyvinyl chloride) foams with closed cells have proven to be excellent in reducing condensation and for sound insulation. Basotect® is a flexible foam with an open cell structure made of thermosetting melamine resin. This material can be used at temperatures up to 240°C. PORON ® High-performance urethane foam material with unique cellular structure and high level of density. It offers exceptional shock absorption, provides high sealing performance, it's flame retardant, heat and water resistant and antistatic material. Antistatic PE and PUR foams are used to protect electronic devices during transport. We use them to make foam inserts and packing pads for boxes, transport containers, etc.

Request for a quote

ROYAL DOORS

United Kingdom

Insulated sectional garage door leaf made from double- skinned, hot galvanized steel sections with CFC-Free PUR rigid foam core, which provides top sound-proofing and excellent heat insulation, keeping the cold out and the warm in.

Request for a quote

ROYAL DOORS

United Kingdom

Sound and heat insulation Insulated door leaf made from double- skinned, hot galvanized steel sections with CFC-Free PUR rigid foam core, which provides top sound-proofing and excellent heat insulation, keeping the cold out and the warm in.

Request for a quote

SC DIA DOXA FOLEX SRL

Romania

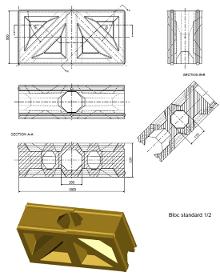

Description PUR-ICF (Polyurethane-Insulated Concrete Forms) modular elements are polyurethane foam blocks with an average density of 45 kg / m3 . A building built of PUR-ICF offers a very high level of thermal insulation as well as good sound insulation, which makes it suitable for use in the construction of any civil buildings (houses, blocks), industrial buildings (warehouses, factories), swimming pools and thermal accumulators, isothermal vegetable and fruit warehouses, etc. By cladding the walls built of PUR-ICF modular elements with various boards (magnesium oxide, gypsum board, etc.), the construction is adapted according to the field of use. PUR-ICF modular polyurethane foam elements come in several construction forms depending on their role in the overall construction. They generally have an area of 1 square meter (200cm x 50cm x 32cm, 11 kg / element)

Request for a quoteResults for

Pur foam - Import exportNumber of results

13 ProductsCompany type