- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- screw conveyors and conveyor systems

Results for

Screw conveyors and conveyor systems - Import export

ROBINSON CO.

Turkey

The Conveyor used in grain, creals and food processing plants in the transport unit. Tube Conveyor is used for the horizontal transporttation of products in flour plants. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

The Tube Screw Conveyor, which is used in grain, grain and food processing plants transportation equipment, is used for horizontal and vertical transportation of powdered or very thin products. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Compact filters are characterised by the fact that they essentially unite fan, filter element and discharge or dust collection facility in one. The capacity range of the compact filters extends up to 20,000 m³/h. Different systems and modes of operation are available for the individual assemblies, resulting in a large number of possible variants. This allows us to offer a large range of solutions for dedusting tasks. Based on our many years of experience, we select the filter media from those available on the market that are best suited for the most diverse types of dust and tasks. Filter hoses, filter bags, filter tubes and filter cartridges are used as filter elements. Cleaning takes place using compressed air impulse, low-pressure purge-air or shaking. Fans from own development and production enable us to design a highly efficient and precise layout. Discharge usually takes place directly into collecting containers, such as dustbins with snap fasteners, or into containers, big bags, or via discharge mechanisms into automatic disposal systems. Screw conveyors, drag conveyors, rotary systems, cellular wheel sluices, double-gate sluices and slidegate valves are available as discharge mechanisms. Intelligent control systems, piping elements, silencers and pre-coating devices for auxiliary dusts are standard items in the range. Naturally we also use our know-how to create needs-based custom solutions.

Request for a quote

TEKNO MILLING MACHINES CO. LTD

Turkey

As Tekno Milling Machines Co. Ltd that founded in Mersin Turkey, we offer turnkey completed seed,pulses,cereals,nuts,spices processing screening crushing and cleaning plants also following agricultural machines and spare parts. Seed Cleaning and Processing Machines : Pre-Cleaning Machines,Classical Screening Machines,Excel Cleaners,Destoners,Gravity Separators,Indent Cylinders,Brushing Machine,Liquid Treatment Machines,Color Sorting Machines,Bagging Machines,Dehullers,Millers Packaging machines: Vertical packaging machines,Rotary Type Packaging Machines,Filling Machines,Seed Counting Machines,Bailing Machine Post Packaging Systems: Carton Packing Machines, Streching Machines ,Shrinking Machines,Vacuum Machines,Metal Dedectors,Printers,Carton Coding Machines,Sticking Machines Silo Systems : Elevators,Conveyor Belts,Screw Conveyors,Silo Systems Please visit our website for all.

Request for a quote

FEMIA INDUSTRIE

France

Installed at the line infeed of granular products such as peas/flageolet beans, it extracts small size waste and sticky waste as well as large waste. Machine primarily comprised of a drum of which the perforations of the final section are adapted to the product processed. Continuous cleaning of the machine thanks to its system of brushes and scrapers. Products to be processed exit from the 3rd section of the drum. Collection and discharge of waste thanks to a conveyor inside the drum (except for small size waste at the beginning of the machine).

Request for a quote

FEMIA INDUSTRIE

France

Provides the product transfer from a piece of equipment located upstream to a piece of equipment located downstream. Can be adapted according to your needs and capacities.

Request for a quote

FEMIA INDUSTRIE

France

Provides receiving, storage and feeding of the product downstream. The dimensions can be adapted according to the capacity of the line and the means of unloading raw materials used. A conveyor belt with high sides which provides the storage and transport of products.

Request for a quote

NOVELTY STEEL

Turkey

Apron feeders come in varying widths, ranging from 0.6 to 3.0 meters, and lengths spanning from 2.4 to 30.5 meters. Lengths exceeding 4.6 meters are primarily used for material conveyance rather than being an integral part of the feeder. Apron feeders exhibit capacities ranging from 91 to 2,270 tons per hour. The power requirements for apron feeders are approximately twice as high as those for comparable belt feeders. Apron feeders are typically employed in situations involving truck dumps or other scenarios where very coarse materials are handled, such as in the feeding of primary or secondary crushers. When an apron feeder is intended for use under a truck dump hopper with an elongated hopper opening, it’s essential to design the hopper with a taper that widens in the direction of horizontal flow for belt feeders. Novelty Structures supplies various types of feeders such as; * Apron Feeders * Belt Feeders * Rotary Table Feeders * Screw Feeders

Request for a quote

GSW SCHWABE AG

Germany

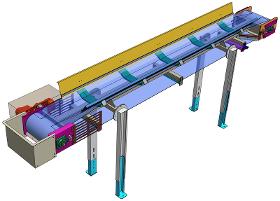

with its compact design using a structural aluminum profile, conveyor system is ideally suited for continuous duty applications in multiple shift environments. using the benefits of modular construction, this conveyor can be readily integrated into new or existing equipment or be used as a freestanding conveyor for bulk handling and loading aplpications. inclination smoothly adjustable steplessly fourwheel drive, 2 steering wheels with parking brake 13 collector rollers, height 20 mm transport cover PUeven, 2 layers, to be used at temperatures from 30 120°C, oiland grease resistant, antistatic funnel (attachment), aluminium anodized drop area pivotable clip/aluminiumclosed bar system suitable for materials to be conveyed from a thickness of 2 mm on for lower thicknesses of materials to be conveyed, allaround corrugated material edges made from celloflex. This reduces the usable width of the material by approx. 70 mm

Request for a quote

NOVELTY STEEL

Turkey

Belt conveyors used for handling bulk solids utilize rubber-covered belts, where the inner carcass of the belt provides the necessary strength to pull and support the conveyed load. The carcass is shielded from damage by layers of rubber, which may vary in thickness depending on the specific application. Belt conveyors exhibit the capability to transport materials across a broad range of rates, spanning from just a few kilograms per minute to several thousand metric tons per hour. ndard troughing angles are commonly set at 0°, 20°, 35°, and 45°. The angle of surcharge is a material-specific property and can be compared to the dynamic angle of repose. The power requirements for belt conveyors hinge on various variables, including the conveyor’s profile, the type of drive-pulley arrangement, belt tensions, belt speed, and idler spacing.

Request for a quote

HO-MA GMBH

Germany

Its flexible design makes the flush-grid belt conveyor particularly compact and its curve radius can be adjusted.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Application Rollers are particularly well suited to the transport of light conveyed material with a smooth and stable underbody. They are used in roller strips, roller tracks, flexible roller conveyors and curved conveyors. They are used in push-through rack storage systems, as deflectors and guide tracks as well as for interlinking different conveyance systems. Load The load-bearing capabilities can be found in the table of dimensions under the “Roller” tab. The conveyance speed of Schulz rollers is up to 2 m per second.

Request for a quote

ILK IHRACAT AS.

Turkey

Our conveyor systems are designed to be the heart of Industry 4.0, the fourth industrial revolution that is transforming the manufacturing landscape. Industry 4.0 is characterized by the integration of digital technologies and automation into the manufacturing process, resulting in increased efficiency, improved productivity, and reduced costs. Our conveyor systems are at the forefront of this revolution, incorporating advanced technologies such as Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML). These technologies enable our conveyor systems to collect and analyze real-time data, optimize production processes, and make intelligent decisions. With IoT capabilities, our conveyor systems can communicate with other machines and systems in the production line, creating a seamless and interconnected network. This allows for real-time monitoring and control, ensuring that any issues or bottlenecks are quickly identified and addressed.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Wire Belt offers a range of straight conveyors designed to ensure efficient operation, improved belt life and maximum cleaning ability. Our straight conveyors feature an open construction with the belt being supported on food grade high density blue polyethylene wear strips clipped to the stainless steel framework. All of our conveyors are suitable for use in hygiene-sensitive environments common to the food and pharmaceutical industries.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

The necessity to spread/separate or converge products while they are moving on a process belt conveyor is a major requirement for a wide range of food, confectionery and industrial applications. In many cases this allows processors to run narrower conveyors saving factory floor space. Coating processes also benefit by separating product and reducing rejection rates.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Field-proven and dependable Flex-Turn® units gently convey products in process around corners while maintaining proper product alignment. They offer the tightest level transfer and smallest inside turning radius available with an open mesh belt. Smooth, non-collapsing product handling minimises potential damage to delicate products. The compact design solves tight production line space problems.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INOTEK MAKINA

Turkey

“U” trough screw conveyors commonly used for industrial prodcess. They are supplied in standard size Q100 to Q500 mm, with direct drive unit and powder proof cover. Inlet and Outlet: Conical, square, rectangular as per customer demand. Motor: Variable motor option Reducer: many drive option: As per customer request pulley drive or chain drive Intermediate Bearing: Specially designed INOTEK hanger bearing for long life.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

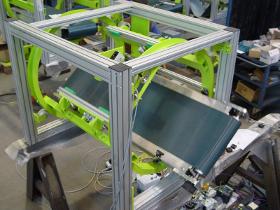

Oswald Metzen, a METZEN Industries’ brand, is specialised in conveyor technology. We provide you with everything you need under one roof: from planning to production and assembly of our innovative, custom conveyor technology which meets the highest quality requirements. Our conveyor systems portfolio: Screw conveyors Construction of silos, containers and their dispensers Belt conveyors Link conveyors Roller conveyors Rotary tables Bucket lifts Two-shaft shredders Big bag systems Transfer lines/return conveyors with inclined lifts Turning stations Transfer devices Pallet conveyors/changers Interlinking systems Chip conveyors We apply our senior engineers’ expertise in the latest technology and our certified welders’, fitters’, steelworkers’ and electricians’ years of experience to our work in our high-tech manufacturing centres and in your plant. We create in-house or externally designed components and systems. We can step in if you require short-term

Request for a quote

INOTEK MAKINA

Turkey

Cold Rolled screw Flight Screw conveyor

Request for a quote

INOTEK MAKINA

Turkey

15 MM TO 500 MM OUT DIA 3-10 THICKNESS Screw Flight Auger auger Flight

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Motion06 Manual Sorting Belt Conveyor is used in those places where bulky luggage is collected centrally from the various luggage lines and prepared for inspection. As a special solution, it can be adjusted to a huge range of conditions, such as conveyor height, positioning of the control system, belt lengths, conveying direction or conveying speed. The heart of the sorting belt is formed by two plastic link conveyors, which are characterised by a very smooth and wearresistant surface and have a far longer life span than roller tables that have been used in the past. The individual pieces of luggage are transported to a certain position by the electronic link conveyor and then manually pushed off in the direction of the conveyor. This procedure makes the work of airport personnel considerably easier.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

For industries in waste treatment and recycling, we offer conveyor systems that include: Roller conveyors, Sliding conveyors, Speed conveyors, Chain conveyors, Transporting conveyors, Spiral conveyors, Bucket elevators, Bunker conveyors

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With a capacity of up to 2500 pieces of baggage per hour, strength and resilience are fundamental. The Motion06 Vertical Sorting Unit Belt Conveyor is used for the distribution and merging of baggage and general cargo between two or three levels. The belt conveyor incorporated into the Vertical Sorting Unit is height adjusting using a top of the line lifting system with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. It is also possible to use it in flight baggage systems with a container system. The belt conveyor is replaced by an appropriate conveyor element for this purpose. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

An innovative new design to allow you to easily sort packages and parcels during your manual sortation process. The unit can also be supplied with an integrated weight scale unit with a digital display. Adjustable Height Telescopic leg sections to raise or lower the conveyor bed height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability. Castors with Brakes 127mm x 38mm Swivel Castors allow easy movement. Castor brakes lock both wheels and swivel simultaneously while the conveyor is in use.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestConnect system is designed to provide rapid assembly of conveyor solutions for changing workplaces. Systems can be easily configured and reconfigured as required to suit your immediate requirements. With a simple 240v power supply and latching connections, the engineering requirement is minimal. Continuous Duty Multiple Drive Motors 20 to 120 Vdc geared motors. Adjustable speed is from 2 to 36 metres per minute. Start/ Stop controls at both ends. Adjustable Height Telescopic legs to raise or lower the conveyor height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability. 50mm Roller Heavyduty precision bearing rollers on 12mm axles for greater durability.

Request for a quote

TIKIR MACHINE INDUSTRY

Turkey

200 meters metal scrap conveyor. It was designed, manufactured and assembled by Tıkır Makina by the world-famous oven manufacturer company, together with 10 pant chutes and one rotary chute. It was commissioned in 2021. The scrap conveyor, which allows the scraps coming out of the presses to flow to the line through pant chutes, fill the baskets at certain points beforehand through the rotary chute. While the scrap conveyor works effectively in this way, it provides efficiency, time savings and safety. The scrap conveyor occupies a very important place especially in the metal processing industry. However, it is possible to design suitable for all sectors. Apart from scrap conveyor, we can produce belt conveyors, pallet conveyors, chain conveyors and roller conveyors. We are waiting for you. Contact us.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The MaxxReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions. Construction MaxxReach Telescopic Boom Conveyors are built to the highest standard with a 10mm thick main case providing one of the strongest, most robust, conveyors of its type on the market. Boom End Lights Two low energy powered LED units are fitted to the front of the conveyor to provide light directly in front of the loading area. Extension Stop Bar A springloaded bar is fitted to the front of the telescopic boom conveyor and it acts as a failsafe stop when the conveyor is extending. If activated, the boom conveyor will stop all functions.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions. Construction BestReach Telescopic Boom Conveyors are built to the highest standard with a 10mm thick main case providing one of the strongest, most robust, conveyors of its type on the market. Boom End Lights Two low energy powered LED units are fitted to the front of the conveyor to provide light directly in front of the loading area. Extension Stop Bar A springloaded bar is fitted to the front of the telescopic boom conveyor and it acts as a failsafe stop when the conveyor is extending. If activated, the boom conveyor will stop all functions.

Request for a quoteResults for

Screw conveyors and conveyor systems - Import exportNumber of results

64 ProductsCountries

Company type

Category

- Conveyor systems (47)

- Conveyor belts (9)

- Agriculture - Machines & Equipment (2)

- Agricultural machines and accessories (1)

- Bottling and filling - machinery and equipment (1)

- Conveyors, overhead and floor (1)

- Crop harvesting (1)

- Erection and dismantling of industrial plants (1)

- Extraction machinery and equipment - minerals and ores (1)

- Flour milling - machinery and equipment (1)

- Flour-milling (1)

- Food Industry - Machines & Equipment (1)

- Grids, gratings and wire mesh (1)

- Machine tools, metal shaping - parts and accessories (1)

- Milling - steels and metals (1)

- Plastics - machines and material for industry (1)