- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sensor technology

Results for

Sensor technology - Import export

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

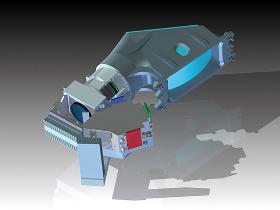

Iron and steel represent a fundamental pillar in industrial production. Precision in the production process of metal plates, sheets and coils is crucial to the efficient use of scarce resources and economic success. As a manufacturer of measuring systems for the steel industry based on optical sensors, Micro-Epsilon offers a comprehensive portfolio without radioactivity that ensures More Precision in all applications regardless of complexity and material properties. With optimized sensor technology tailored to the respective application, innovative mechanical design, as well as cooling and protective devices, the systems meet the challenges of the processes. The high-performance signal processing and analysis software makes the systems the leading optical measuring systems on the market which detect the following parameters

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The optoNCDT 1220 is the entry-level model for precise measurements in industrial automation. This compact laser triangulation sensor measures displacement, distance and position with high precision. Based on an excellent price/performance ratio, this sensor is ideally suited to measurement tasks involving a large number of pieces. Therefore, the sensor can be used in all fields of automation technology, e.g., in machine building, 3D printers or robotics.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

Sensors are the sensory organs of technical equipment and important components in all areas of automation. Temperatures, pressures, movement and a variety of other analogue values are detected, converted and digitally transmitted to the higher level field system. MicroControl systems are ideally suited for these applications. Up to 10 times faster and a significantly higher data throughput, 16…24 bit resolution for higher accuracy, a wide temperature range and high IP rating provide higher operating reliability, e.g. in food technology or chemical industry.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

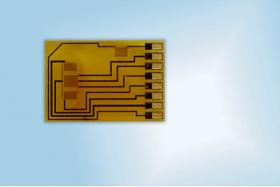

The IST AG MicroFlowSens (MFS) technology was developed for fast flow measurements. Due to the membrane system, the thermal mass is reduced to the minimum resulting in a very fast response time and low power consumption. In addition to measuring flow rates, the MicroFlowSens offers an outstanding sensitivity and is able to detect flow direction. The MFS flow sensor is optimal for limited space system integration and is available as integrated sensor on a PCB. Further advantages of the MFS thermal mass flow sensor include: — Excellent solution for applications with high flow rates and fast response time in CTA mode — Very high measuring dynamic with CTA mode (10'000'000 : 1) without bypass — Excellent for the measurement of very low flow rates and leakage detection with bridge mode — High chemical resistance against aggressive gases and vapors — Different sensitivities, circuit topologies available — Detection of flow direction — Customer-specific sensor layout upon request

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

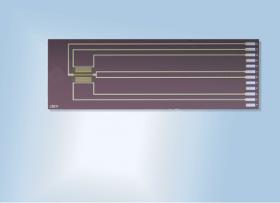

The SFS01 is particularly suitable for low flow velocities up to 3.5 m/s (in gases). It shows very fast measurement results of the flow rate as well as the flow direction. The Silicon Flow Sensor SFS01 offers three main characteristics: — Very fast response time <5 ms — Very low energy consumption — Easy system integration including temperature compensation Well-adapted channel geometries allow the performance of the sensor to be optimally aligned to the desired application. The SFS01 flow sensor is ideally suited for space-limited applications, but can also be easily upgraded to complete ready-to-use systems. Suitable application areas for the SFS01 flow sensor are flow measurements in battery-operated / portable devices, air conditioning technology (HVAC), automation technology as well as process and control engineering.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

Stable and robust humidity sensors with ultra-fast response time are often required in applications involving meteorology – not only in normal conditions, but also under elevated environmental constraints such as extremely low temperatures, high radiation levels and under extreme condensation. Such applications need fully tailored solutions, such as those provided by the Innovative Sensor Technology IST AG P14 Rapid. The P14 Rapid humidity sensor combines speed and full range operation in an ideal way. The sensor is capable of measuring 0 % RH to 100 % RH (maximal dew point +85 °C) with a capacitance of 140 pF ±40 pF (wired) / 180 pF ±50 pF (SMD) (at 30 % RH and +23 °C) and operates within a temperature range of -80 °C to +150 °C.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

Stable and robust humidity sensors with ultra-fast response time are often required in applications involving meteorology – not only in normal conditions, but also under elevated environmental constraints such as extremely low temperatures, high radiation levels and under extreme condensation. Such applications need fully tailored solutions, such as those provided by the Innovative Sensor Technology IST AG P14 Rapid. The P14 Rapid humidity sensor combines speed and full range operation in an ideal way. The sensor is capable of measuring 0 % RH to 100 % RH (maximal dew point +85 °C) with a capacitance of 140 pF ±40 pF (wired) / 180 pF ±50 pF (SMD) (at 30 % RH and +23 °C) and operates within a temperature range of -80 °C to +150 °C.

Request for a quote

NORELEM FRANCE

France

Housing thermoplastic. Version: Operating principle: Magnetic. Rating: IP67. Note: If the actuator is within the switching range (safety door closed), the safety contacts and, if applicable, the signal contacts of the safety switch are activated. The contact is thus closed via a magnet (magnetic field). Form A: Actuator on one level to the safety switch. Form B: Actuator offset by 90° to the safety switch.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The new strain gage amplifier with IO-Link interface enables digitalization of the measurement technology right from the sensor. Its compact design and high degree of protection allow the instrumentation amplifier to be used practically anywhere in the field. Strain gage sensors typically have an output voltage of a few millivolts. In industrial environments, e.g. in the vicinity of electric motors or frequency converters, interference can affect the measurement result when transmitting analog signals. This is reliably avoided using the new strain gage amplifier with IO-Link interface. The analog link between the sensor and instrumentation amplifier is kept as short as possible, the standardized IO-Link communication is fully digital and interference-free. The amplifier is powered directly via the IO-Link interface – a standardized 5-wire cable with M12 socket. Strain gage sensors can be connected via a 4-pin M8 connector.

Request for a quote

SIKO GMBH

Germany

With flexCoder technology, the MSAC200 can be flexibly adapted to the customer's design and provides precise absolute values with high installation tolerances at the same time. It is basically possible to adapt the encoder and the magnetic ring for precise fitting, for example in motors. An additional feature is the high reading distance ≤0.6 mm and axial tolerance of ±0.2 mm to facilitate the design of the overall system and enable use in dynamic applications. Customer-specific design. Integration into small installation space possible. Absolute resolution up to 21 bit. Repeatability 0.01°. Reading distance ≤0.6 mm. Interface BiSS C, SSI. Optional analog real-time signal output Sin/Cos 1 Vss. Industrial and medical applications e.g., motor feedback, handling automation and robotics.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental magnetic measuring heads offer maximum precision over the full range of measurements. As a result of the magnetic operating principle and the robust mechanical construction, they are insensitive to soiling and are therefore ideally suited to use in production facilities. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development etc.). Typical applications include: —Monitoring both slow and fast movements between machine parts —Measurements of position and positional changes in components and structural foundations, of servo regulators, valve and robot controllers —Measurement of growth, and so on The incremental displacement sensors are based on a magnetic principle: consisting of a magnetic scale and a multi-slot reading head that responds to changes in magnetic flux, they detect linear movements with high precision and resolution.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental magnetic measuring heads offer maximum precision over the full range of measurements. As a result of the magnetic operating principle and the robust mechanical construction, they are insensitive to soiling and are therefore ideally suited to use in production facilities. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development etc.). Typical applications include: —Monitoring both slow and fast movements between machine parts —Measurements of position and positional changes in components and structural foundations, of servo regulators, valve and robot controllers —Measurement of growth, and so on The incremental displacement sensors are based on a magnetic principle: consisting of a magnetic scale and a multi-slot reading head that responds to changes in magnetic flux, they detect linear movements with high precision and resolution.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental magnetic measuring heads offer maximum precision over the full range of measurements. As a result of the magnetic operating principle and the robust mechanical construction, they are insensitive to soiling and are therefore ideally suited to use in production facilities. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development etc.). Typical applications include: —Monitoring both slow and fast movements between machine parts —Measurements of position and positional changes in components and structural foundations, of servo regulators, valve and robot controllers —Measurement of growth, and so on The incremental displacement sensors are based on a magnetic principle: consisting of a magnetic scale and a multi-slot reading head that responds to changes in magnetic flux, they detect linear movements with high precision and resolution.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This miniature force sensor was optimised with respect to its height and is, at only 3.4 mm, the lowest known sensor with strain gage technology. Hardly higher than the diameter of its connection cable, it can also be housed in conditions where space is limited. Along with its minimal geometry, the force sensor is also particularly light. It has a high resonance frequency to follow quickly changing load alternations. Despite its extreme miniaturisation, in its application it remains completely robust and suitable for industry, not only with regard to the highly flexible cable connections or the full welding of sensors for the measurement ranges ≥ 0 … 10 N. The miniature compression force sensors are flat, cylindrical discs with covered bottoms. The central load application button for taking on compression forces is an integrated part of the top, which is the sensor‘s membrane.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The demand for aluminum is constantly increasing due to its special technical properties. It can be made thinner and thinner as the strength increases. This is accompanied by tight manufacturing tolerances, which require measurement technology with more precision. As a manufacturer of measuring systems for the aluminum industry, Micro-Epsilon offers a comprehensive portfolio based on optical sensors without radioactivity that ensures More Precision in applications regardless of complexity and material properties. Optimized sensor technology tailored to the respective application, innovative mechanical design, as well as cooling and protection devices enable the systems to meet the needs of the processes. The high-performance signal processing and analysis software makes the systems the leading optical gauges on the market which detect the following parameters

Request for a quote

SIKO GMBH

Germany

The AP05 position indicator guides the user intuitively to the correct machine setting in the case of product or format change. The optimized backlit display indicates target values and actual values straight to the point. Two LEDs show the machine operator precisely the direction whereto the adjustment is to be performed.The AP05 helps avoid wrong machine settings and enhances process safety of flexible production machines. Electronic position indicator with bus interface. Backlit two-row LCD. Display of target and actual value displays with integrated alignment. User guidance through status LEDs. Hollow shaft with Ø 20 mm and clamping ring made of stainless steel. Enhanced shock resistance owing to protective display glass. Integrated RS485 interface, CAN bus as an option. Robust sensor technology unit thanks to magnetic scanning. Mechanically compatible with the AP04 and DA04 position indicators. IP53 type of protection, IP65 as an option.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Inductive displacement sensors using the principle of the differential transformer (LVDT) can be used to measure displacement and, indirectly, magnitudes that can be converted into displacements such as force, pressure, strain, torque, vibration and so forth. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development, etc.). Applications include measuring, controlling, regulating and monitoring both slow and fast movements between machine parts, measurements of position and positional changes of components and structural foundations, servo regulators, valve and robot controllers, growth measurements and so on. Their design is robust - the internal coils and electronics are potted - as a result of which the sensors can easily withstand shock and vibration.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This force measurement chain was developed for applications where a low cost solution is more important than achieving high levels of accuracy. The sensors strain gauge technology allows the measurement of static and dynamic forces. The load cell is also designed for applications that provide only little space due to its compact design. These properties, together with the sensors dust protection, make the measuring chain suitable for a wide range of applications, such as Industrial manufacture Manufacture of customized machinery Geological investigations Motor vehicle engineering Commercial agriculture Bridge building The body of the sensor is a flat, cylindrical disk, into which a domed force application knob is integrated. It is important that the force is applied axially to the center of the sensor. The domed form, however, minimizes the effect of a force that is not exactly axial.

Request for a quote

SIKO GMBH

Germany

The bus-compatible AP10 position indicator serves for monitored format adjustment in order to reduce setup times and enhance machine efficiency.Readability has been optimized to achieve intuitive user guidance. The backlit display clearly indicates target and actual values two-row position indicator for representing target and actual values and the two LEDs clearly show the direction to be set. Electronic position indicator with bus interface. Stainless-steel hollow shaft ø20 mm, up to ø25.4 mm as an option. Backlit display. Two-line LCD for target and actual values. Reset, incremental measurement, offset via keyboard. Integrated RS485 interface, CAN bus or IO-Link as an option. Robust sensor technology unit thanks to magnetic scanning. User guidance through status LEDs. Mechanically compatible with the DA09S position indicator. IP53 type of protection, IP65 as an option.

Request for a quote

SIKO GMBH

Germany

Absolute indicator with Industrial Ethernet interface which enables process-capable and intuitive positioning for manual machine adjustments. The display and evaluation of target and actual values ensures monitored format adjustment. Integrated Industrial-Ethernet-Fieldbus.Backlit two-row LCD. Display of target and actual value displays with integrated alignment. Stainless-steel hollow shaft ø20 mm, up to ø25.4 mm as an option. Robust sensor technology unit thanks to magnetic scanning. User guidance through status LEDs. Mechanically compatible with the DA09S and AP10 position indicators. IP53 type of protection, IP65 as an option

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The force measuring chain has been developed for applications where the requirements for precision are not the primary focus, but rather where an economical purchase price and simple functionality are the key criteria. The sensor‘s strain gauge technology allows both static and dynamically changing forces to be measured. The large display means that the force acting on the sensor can be read easily. The four integrated threaded holes allow the sensor to be integrated quickly and easily into existing production and assembly equipment. Typical applications include: —Testing the strength of welded joints —Sports medicine —Monitoring the clamping force of hose connections The body of the sensor is a flat, cylindrical disk, into which a domed force application knob is integrated. It is important that the force is applied axially to the center of the sensor.

Request for a quote

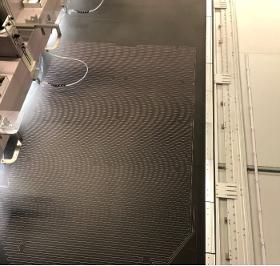

TFP TECHNOLOGY GMBH

Germany

We at TFP use our special wire and fiber laying technology to create sensors for large dimensions to measure pressure, humidity and monitor structural composite parts. Please contact us for further information.

Request for a quote

ALPHA LASER GMBH

Germany

With the new ALO manual welding laser, you can either work manually or with an axis of rotation for circular welding. The working chamber is easily accessible via leather curtains, but the welding itself still takes place in the shielded laser safety area. The spacious working chamber can be loaded quickly through various openings, without opening doors: a large opening at the front ensures easy access to the welding chamber. The slots on the side enable the operator to position longer components in the machining area and to weld them in a laser-safe manner. Another passage on the bottom of the working chamber allows loading from below. The laser safe leather curtain offers certified laser protection so that the laser device can be placed in any work environment. The armrest is extremely comfortable - ensuring relaxed work. A lot of attention was also paid to good ergonomics. A high-quality extraction system with filter is integrated as standard.

Request for a quote

BURRE HYDRAULIK GMBH

Germany

Constructed according to your application Constructions from 2 ways up to 14 ways All ports are noninteracting and every one comes with its own leakage connection. This makes external surveillance of each port possible Media: air, water, oil, fat, emulsions Sensor technology optional

Request for a quote

BEFORT WETZLAR OD GMBH

Germany

Based on the longstanding experience in the field of industry optics, Befort is your optimal partner for the new development and production of customer specific optics and mechanooptic systems. Our experts will find and realize the best solution for your optical problem. Solutions may be based on a variety of technologies, such as spherical, refractive optics, but also freeform optics, micro optics, diffractiveaspheric or plastic optics. Furthermore, we integrate electronics, sensor technology, controls and image processing jointly with external partners. OUR SOLUTIONS ARE APPLIED IN A VARIETY OF MARKETS Medical technology Automotive Mechanical engineering Industrial image processing Laser technology Defense Sensor technology

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

The key to the successful optimisation of compressed-air systems is data. The METPOINT® range of measurement equipment with sensor technology and monitoring provides the data base for the evaluation and assurance of the compressed-air quality and for the identification of hidden cost drivers. Our measurement equipment can also be employed for the extension of plants and for the early elimination of malfunctions. With our sensor technology, you can capture residual oil content, residual humidity, volume flow and pressure – constantly, faultlessly and with exemplary precision. Our Monitoring and Data Logging makes all the relevant data accessible to you and your employees at a glance, ensuring the safety of your processes and the quality of your products. In this way you can take your energy management and quality control requirements to the next level of success.

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Non-contacting multi-turn rotary sensor with revolutionary NOVOTURN technology. Very compact, accurate and durable.

Request for a quote

INFICON GMBH

Germany

A new direction in features, function and value Integral to Compass is the INFICON patented heated diode sensor technology, delivering outstanding sensitivity to all refrigerants yet resisting jobsite contaminants such as dust, dirt and oil. For maximum versatility and ease of use, Compass has features such as rechargeable batteries, the ability to operate on AC power, adjustable high/low sensitivity and a series of LED leak indicators. The ergonomic design with rubberized grip fits your hand perfectly for comfortable, secure operation.

Request for a quote

SIKO GMBH

Germany

With bus interface Profile AP04: Electronic position indicator with bus interface Compact design Hollow shaft, max. Ø 20 mm Easily readable, two-line LCD for target and actual values Reset, incremental measurement, offset via keyboard integrated RS485 interface, CAN bus as an option Robust sensor technology unit thanks to magnetic scanning User guidance via bicolor LED

Request for a quoteResults for

Sensor technology - Import exportNumber of results

158 ProductsCountries

Company type

Category

- Sensors (61)

- Automation - systems and equipment (4)

- Energy sources, alternative - equipment and systems (4)

- Measurement - Equipment & Instruments (4)

- Measurement and control instruments (4)

- Measurement and regulation equipment and instruments - pressure (4)

- Thermometers (4)

- Connectors, electronic (3)

- Flow meters (3)

- Laser - cutting and welding machines (3)

- Measurement and regulation equipment and instruments - output and flow (3)

- Electrical & Electronic Components (2)

- Electronic components (2)

- Gas detectors (2)

- Mechanical engineering - custom work (2)

- Robotics (2)

- Shearing machine tools (2)

- Tools, pneumatic (2)

- Accelerometers (1)

- Bottling and filling - machinery and equipment (1)