- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- die presses

Results for

Die presses - Import export

CIC - KLAUS CZERWONKA

Germany

Forged parts made of steel, stainless steel and aluminum including mechanical processing. Pressed brass blanks including mechanical processing, also on rotary transfer machines. Sintered parts made of sintered bronze, sintered porous brass and stainless steel. Filter elements for air, liquids and fuel made of sintered ball material or mesh.

Request for a quote

ROTAS SWORN AND ORDINARY TRANSLATION OFFICE

Poland

Rotas office offers multi-phone rental . These are microphone sets consisting of a large number of gooseneck microphones, perfect for all events attended by a large number of speakers, such as discussion panels or press conferences, meetings of supervisory boards, meetings of city and municipal councils, teleconferences. The built-in loudspeakers ensure that individual meeting participants can hear each other perfectly, even over long distances. The set includes a central unit, desktops for the presenter (from 2 to 6) and desktops for other meeting participants (maximum 60).

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Large-volume pneumatic cylinder with through-piston rod for use as a die-cushion press balancing cylinder in a mechanical press.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Housing parts made of steel, stainless steel, aluminium, brass. Made of solid material, profile material, cast blanks and pressed parts. With and without surface treatment.

Request for a quote

CHRISTIE INTERNATIONAL LIMITED

United Kingdom

A range of natural premium cold pressed Rapeseed Oils, Flavoured Infusions and Sprays

Request for a quote

HEMOGUM

Serbia

In its production Hemogum uses elastomere injection presses, transfer or injection procedure presses.Each press uses the “intelinjekt" system which integrates the termotrac and mastertrac automatition systems. "Intelinject' injection controlling system and closet) loop control provides the precision and repetition in regulation of presses, ntegrates the mastBftrakt and termotrakt software. Constant control of all pioduction parameters of parts guarantees tneir compliance win me required nemi.

Request for a quote

METFIX GROUP

Kazakhstan

Folding spring dowel with hook The main purpose is to attach lightweight structures to plasterboard, particle board, and other hollow building materials..

Request for a quote

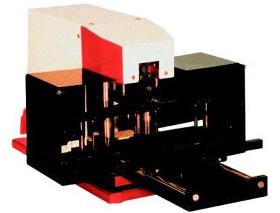

FRIMO GROUP GMBH

Germany

Hydraulic presses for a broad variety of pressing, foaming, punching and forming tasks FRIMO HyPress standard machines can be adapted to fit table size, stroke, clearance, and press force requirements. Numerous options are available including safety packages, pivoting rams and tables, tool change systems, automation solutions, and complete customizations. The standard presses are designed as bolted, welded structures. The machine feet, head and sides are manufactured with high precision and fastened with fitting keys. The ram is guided via prisms and can be easily readjusted. It can alternatively be column-guided.

Request for a quote

FRIMO GROUP GMBH

Germany

"Combi" tools allow different technologies to be combined in a single step (in one tool) for more efficient plastic component production. Typical technologies applied in combined processes (depending on the requirements) are foaming, forming, laminating, edge folding, punching and joining. These processes allow different materials and material combinations to be used. "Combi" tools enable a very fast and cost-effective production process with minimized space requirements. Based on their longtime expertise and completion of numerous serial projects, FRIMO is able to supply optimized tooling solutions that perfectly meet the product and customer requirements. These range from small tools to special tools for large components for a nearly unlimited range of plastic applications. Our tools are available in steel or cast steel, as well as in aluminum, cast aluminum or nickel shells. For special applications, FRIMO also offers tools with interchangeable inserts, allowing the most efficient

Request for a quote

FRIMO GROUP GMBH

Germany

The combination of multiple technologies/procedures in one step is called OneShot technology. Semi-finished products (e.g. renewable raw materials such as natural fibers) and decorative materials (e.g. textiles) have to be handled in one production step to finish a component, such as a door panel. FRIMO has developed a modular system that allows for simple and customized configuration of a OneShot plant with all necessary tools. The following units can be integrated into such a plant: feeding station, heating station, calibrating station, material assembly station, press with OneShot tool, part-removal station.

Request for a quote

FRIMO GROUP GMBH

Germany

Composites are engineered materials made from two or more materials with significantly different physical or chemical properties. Their mechanical and physical properties depend on the type and proportion of the base materials and the parameters of the manufacturing process. Due to composites, very light and durable plastic parts can be produced. Composites may be prepared as layers , fibers, particles or penetrating composites , but the actual composite material usually only arises during the shaping process in the tool . FRIMO has extensive technical expertise and many years of experience in developing and manufacturing plants and tools to process composite materials such as CFK, GFK, NFPP, HFPP, LFT, GMT and BMC and supplies for the production processes such as RRIM, SRIM / GMPU, Long Fiber Technologies, NFI, or RTM tailor-made manufacturing equipment.

Request for a quote

FRIMO GROUP GMBH

Germany

For sophisticated decorative materials Press laminating is mainly used to process materials that are unsuitable for vacuum processes, such as textiles, materials with and without foam backings or non-stretchable cover materials like leather or Alcantara. Processing these materials requires high quality tooling and machinery to ensure the quality of the grain, the soft touch and the color remain intact. The decorative element and the substrate are usually laminated together by being pressed between two hard instruments. Precise decor positioning and tool arrangements ensure optimal laminating conditions. Other forms of laminating include leather laminating and membrane laminating, which combines press laminating, edge folding, trimming.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The solid machine design of the h-frame press with section steel frame structure is the basis for integration of multi-head tools. Equipment with up to 16 ultrasonic generators allows for cycle time-optimized process sequences in one processing station. The weld tools are moved far up by means of a pneumatically operated H-frame so that large-volume plastic components can be comfortably loaded into the work station. Additional solutions available for quick and safe tool change.

Request for a quote

ECOPEATMIX

Russia

Pressed sphagnum peat moss slabs (9 liters) are the finished product for covering any prepared surface for arranging grass plots, beds in public gardens, parks near houses, railroad beds and highways and bedding out grasses, flowers, various herbs and decorative plants. Sphagnum pressed peat moss slabs are produced from high-moor milled peat dried to 22-28% moisture and pressed into the rectangle form. Content of nutritious elements (mg/100g of dry substance): Nitrogen (N) – not less than 200 mg Phosphorus – not less than 300 mg Potassium – not less than 300 mg Trace substances: Cu, B, Mn, Mo, Zn, Fe Dimensions of a slab: 470 x 150 x 30 mm, thickness of a slab 25 – 35 mm Weight of a slab: 1200 – 1500 g various subject to moisture

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP D 020 Automotive Press for pressing of rivet nuts, connectors, etc. Usage To reline of these connectors Automotive Press was formerly developed. Meanwhile, this device will multiply its application when it comes to press- fit components into the PCB (eg connectors). Also for joining several PCBs or PCB components, the press can be used. Operation Through the use of different tool inserts, which can be easily replaced in the nut tool, different assembly operations can be greatly facilitated, that have often been carried out laboriously on a toggle press. Due to the size of the motor press D 020 can be permanently mounted in the workplace or on a mounting bereitgestelllt car. The operation is simple: the circuit board is inserted with the part to be pressed in the operating range of the device against the stop. Then a limit switch triggers the workflow. By a nearly closed guard is no danger to the operator.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

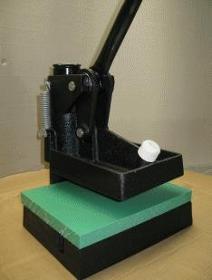

1A STAR TECHNISCHE KUNSTSTOFFE GMBH

Germany

We started using this machine for soft materials in 2013 where a lot of customers asked us for another smaller option beside a swing beam press! With the STAR MA3 we can offer you a solution! It works exactly like a bigger swing beam press. The cutting head is attached to a cylinder on the backside of the machine. The force isn't made by hydraulic systems. It is made manually through a 812mm long handle on the front of the machine. The head is inclined a few degress like a bigger swing beam press. This is balanced if the cutting head is under force. This many is used worldwide for small quanitities for cutting leather, pictures or laboratory works. But it can also be soft materials like in the following list: •Abrasives •carpets •elektronic parts •foamed plastic •Shoes •rubber •Leather articles •packaging •Paper •Textiles

Request for a quote

WIZZ CREASING MATRIX

Turkey

High Quality and competitive prices from Turkey

Request for a quoteResults for

Die presses - Import exportNumber of results

20 ProductsCountries

Company type