- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- shaped joint

Results for

Shaped joint - Import export

ESTIMET SP Z O.O.

Poland

Our specialized team enables us to carry out virtually any task related to the rolling of metal sheets up to 3000 mm in length and up to 25 mm in thickness. For complex shapes, we use micro-joints at key locations, and they will be removed after the process is complete. By bending the ends of parts, we eliminate the need for runouts, which translates into significant material savings. We roll rolls, ovals and cones, but we are also ready to meet the special requests of our customers. We have modern machinery, which guarantees precise execution of each order. We always meet the agreed deadlines, working efficiently and effectively. We offer customers a comprehensive service, which also includes sheet metal cutting service.

Request for a quote

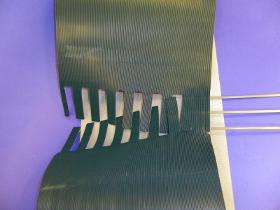

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The mechanical joint system ERO Joint® keeps the minimal diameter of the belt and is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® splice shape may be adapted in order to increase the mechanical resistance. Mechanical splicing system ERO Joint® are also possible in conveyor belts with sealed tension members (like Gates PosiClean® and FlatClean FC12™) ->More about PosiClean® ERO Joint® belt The ERO Joint® conveyor belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quote

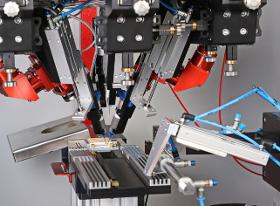

NANOSYSTEC GMBH

Germany

VersaSolder uses selective laser soldering for applications where other methods fail. A laser beam heats an area without impacting the surrounding the key advantage of this non-contact joining technique.A lens assembly focuses the laser power which melts the solder onto the working area. It is tailored exactly to the specific shape of the solder joint and the beam may be circular, elliptic or a straight line. An optional pyrometer measures the temperature in the melt pot and the electronic actively regulates the power profile. Multiple solder heads heat various areas at the same time and a symmetrical arrangement reduces shift. In order to achieve higher productivity, nanosystec developed the Multi Beam Optic (MBO). It generates a number of sub beams processing more than one connection in the same time – up to 40 individual spots have been demonstrated.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

In interaction with the sonotrode, the anvil produces and shapes the joint and thus is one of the core components of the ultrasonic sealing process. Sealing of films requires focusing of the energy by means of the tooling profile, which is mostly mounted to the anvil. Highest rigidity and plane parallelism ensure best joint quality. Anvil profiles are essential for the quality of the weld result and are produced to customer requirements and adapted to respective applications.

Request for a quote

KLN ULTRASCHALL AG

Germany

The riveting process creates irresolvable interlocking bonds. This is achieved by forming or reforming of thermoplastics. In most cases in this procedure only point-shaped or segmented joints are realized. In contrast to welding of two components there cannot be achieved hermetic joints. A particular version of this procedure is the bonding of plastics with metals, textiles and cardboard. The method is frequently used for wooden decoration parts, into which a chrome decoration strip has to be embedded. As a rule the hot form riveting is carried out in a one-cycle process. A heated riveting stamp forms the riveting head under pressure. After forming the stamp is shortly cooled down in order to avoid adhesion of the plastic material on the thermal riveting stamp. After this short cooling phase the riveting stamp is again moved above.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FIP ARTICOLI TECNICI S.R.L.

Italy

GP-type steel finger joints suitable to absorb deck displacements of up to 250 mm (+ I 25) consisting of: • anchoring/support system made of patented anchor rods of suitable section and length; • suitably dimensioned and shaped stainless steel gutter. • active upper part consisting of an overhung metal finger system obtained by the processing of COR-TEN steel plates equipped with bolts, nuts, washers etc.; • under-pavement waters drainage consisting of stainless steel "L"-shaped profile. JOINT TYPE TOTAL MOV. (mm) HEIGHT H (mm) WIDTH*X (mm) GAP *Y (mm) ANCHORS Z (mm) ANCHORS T (mm) ANCHORS ø (mm) GP 50 50 30 400 60 80 45 M16 GP 100 100 30 470 80 105 45 M16 GP 150 150 35 545 105 130 45 M20 GP 200 200 40 620 130 155 45 M24 GP 250 250 45 820 155 180 45 M24 Length of finger element = 480 mm * average gap POS. DESCRIPTION MATERIAL A Finger element S355J2WP EN 10025 B Sealant EPOBLOCK ME Legante C Transition strip EPOBLOCK ME 3C D Bedding EPOBLOCK ME 3C / Beton FIP E Anch

Request for a quoteResults for

Shaped joint - Import exportNumber of results

7 ProductsCountries

Company type