- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bakery

Results for

Bakery - Import export

TALLERES ZELAIETA, SL.

Spain

Machine designed to produce high hydrated bread (70-90% water). Due to its special process: tough flour, important resting time, less damage when cutting, etc., permits to produce high quality bread and several shapes. The TXA-ROLL-TOP-800 has a “multiroller” which laminates and extends the dough, which has been already unloaded to the belt and gives 40-50% extra length to the dough. After cutting pieces are separated in different variable ways and automatically panned in tray or board, manually handling the trays. Control through automat, which allows 16 different programs. The machines tells when the dough is finished to joint the following one. Tray or board dimensions: 500-800 mm max. Types of bread: the classic Ciabatta in all its shapes: basto, baguette, rustic, rustic with pointed ends, minis, etc.

Request for a quote

TALLERES ZELAIETA, SL.

Spain

Unique, different, accurate. The absorption of the dough varies depending on the WT, avoiding damage and degassing of the dough. Manufacture with oil system, with the possibility of non oil system, for small productions. Piece counter with automatic stop. Optional: Twin piston Divider PTZ-2P (35-300 g ) 3.600 p/h. Spiral dough feeder (for tough or dry dough). Longer rounding belt. Electric wt control. Electronic variator PTZ-VE (900 to 2100 p/h).

Request for a quote

TALLERES ZELAIETA, SL.

Spain

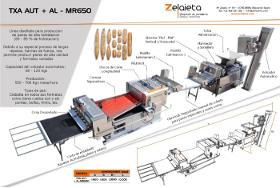

Line designed for production of high hydration breads (65-85% hydration). Automatic tipper capacity: 80-125 Kgs. Production: 550-700 Kgs dough/hour. Due to its special process of long rest, strength flours, we allows to produce high quality breads and varied formats. Types of bread: the classic Ciabatta in all its shapes: basto, baguette, rustic, rustic with pointed ends, minis, etc.

Request for a quote

TALLERES ZELAIETA, SL.

Spain

Machine designed to produce high hydrated bread (70-90% water). Due to its special process: tough flour, important resting time, less damage when cutting, etc., permits to produce high quality bread and several shapes. The TXA-AUT-ROLL has a “multiroller” which laminates and extends the dough, which has been already unloaded to the belt and gives 40-60% extra length to the dough. The longitudinal cut process, separation of the pieces through bands, guillotine section…, (transversal cut) and loading of the product into board or tray (flat or corrugated), is carried out automatically. Types of bread: the classic Ciabatta in all its shapes: basto, baguette, rustic, rustic with pointed ends, minis, etc.

Request for a quote

TALLERES ZELAIETA, SL.

Spain

Designed to produce high hydrated bread (70-90% water). Due to its special process: tough flour, important resting time, less damage when cutting, etc., permits to produce high quality bread and several shapes. The TXA-MAN-ROLL has a “multiroller”, to laminate and spread the piece of dough, giving the dough an extra 40-50% strength. The collection of the product already cut-mould is manual. Types of bread: the classic “ciabatta” in all its shapes: baston, baguette, rustic with pointed ends, minis, etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TALLERES ZELAIETA, SL.

Spain

Machine designed to produce high hydrated bread (70-90% water). Due to its special process: tough flour, important resting time, less damage when cutting, etc., permits to produce high quality bread and several shapes. The TXA-ROLL 800 Plus has a “multiroller” which laminates and extends the dough, which has been already unloaded to the belt and gives 40-50% extra length to the dough. Includes a prelamination roller. After cutting, the pieces are separated trough different variable bays and unloaded automatically obtaining a perfect depositation: Tray by tray. Control through automat, which allows 16 different programs. The machines tells when the dough is finished to joint the following one. Tray or board dimensions: 500-800 mm max. Types of bread: the classic Ciabatta in all its shapes: basto, baguette, rustic, rustic with pointed ends, minis, etc.

Request for a quote

FORMEX MAQUINARIA

Spain

Units to apply topping such as chocolate pieces, sugar, peanuts, hazelnuts, grated coconut, almonds and granules on the already dosed product. -Very flexible machine, adapts to all types of topping. It works multi-product. -The topping is deposited in an outlet hopper and moves along a belt until it falls through funnels and remains on top of the product. A screed would maintain a homogeneous measure of the product on the belt. This system favours the regular depositing of the fragments throughout the product. Adjustable output speed and product flow. -There are 3 ways to adjust the dosage: -By the flusher to the deposit (mechanical). -By the speed of the belt with sugar (electronic). -By time of movement of the belt. -Modifications can be made by touch screen with different programmes depending on the product. -Machine that works as an independent unit. A conveyor is added and it works autonomously.

Request for a quote

FORMEX MAQUINARIA

Spain

•Automatic and modular workstations for the production of muffins, cupcakes and other bakery products. •Modular lines consist of a series of machines prepared to flexibly meet your requirements. Mono-production or multi-production, mid-range or industrial, depending on your needs. •By studying your product and desired output we can create a workstation to suit your needs. The configurations are very versatile, allowing to extend the working line to increase production or diversify the product. •MODULES: Tray Loader + Capsuling Machine + Muffin Dispenser / Cupcake Dispenser / Pastry Dispenser + Topping Dispenser + Injector of already baked product. •The technical specifications vary depending on the modules and the final configuration of the line, please ask for a personalised quotation for the details of your desired line.

Request for a quote

FORMEX MAQUINARIA

Spain

MACHINE CHARACTERISTICS: -Production line consisting of three stations: oInjector with three rows of nozzles to inject 27 croissants simultaneously, and with three needles per nozzle so that the product is well distributed. oGelatine station that impregnates the croissants with gelatine. oTopping unit with ribbon for the chocolate chips to fall onto the product and get stuck in the gelatine layer. -Injection quantity and injection speed are set on the screen, allowing a more precise adjustment. -Between the injection belt and the gelatine belt, which is made up of cords, there is a transfer belt so that the croissants fall correctly in position and without turning, and are stacked for the gelatine shower. ADVANTAGES -Automated production for high volume production. -Three processes are completed in a reduced space.

Request for a quote

FORMEX MAQUINARIA

Spain

PRODUCT: -Diversity and complexity of products: -Living element: variable volume and shape. -Delicate and fragile: easy to damage during handling. Coated with gelatine, chocolate, etc. -Unsteady: Lightweight, easily dislodged. CHARACTERISTICS OF THE MACHINES: -Versatile production line that can operate with different types of trays and papers. -An Omron technology robot arm allows us to increase the versatility and efficiency of the whole line, as the same robot can work with different tray formats. -A dispenser for muffin and fiancée capsules that places the capsules on the tray. -A muffin dispenser with seven nozzles, with volumetric dose regulation. -Two interchangeable seed dispensers. ADVANTAGES -Uniformity of the product. -The automation of the whole allows us to obtain a production of approximately 8,400 macarons/hour or more than 8,000 units/hour in muffins, madeleines or financée.

Request for a quote

FORMEX MAQUINARIA

Spain

•Dosing machine for making muffins, muffins and other food products with two-coloured dough. •Machine made for the dosing of two different doughs in the same capsule or mould. •The tank is divided into two parts to place each mixture in one of them. •The dosing outlet has off-centre nozzles to be able to adjust the depositing point of the mass. •The dosing parameters for each product can be changed independently via the touch screen. •Approximate production of 170-230 trays/hour approx.

Request for a quote

TALLERES ZELAIETA, SL.

Spain

Machine designed to produce high hydrated bread (70-90% water). Due to its special process: tough flour, important resting time, less damage when cutting, etc., permits to produce high quality bread and several shapes. Within the TXA-MINI the piece of dough has to be spead manually. After the division-mould automatically, the collecting of the product is manual. Types of bread: the classic Ciabatta in all its shapes: baston, baguette, sandwich, small, pointed ends, etc.

Request for a quote

TALLERES ZELAIETA, SL.

Spain

Vertical type with: feeding Belt, prelamination Roller, tefloned lamination rollers, removable collecting belt, etc. Porgressive stretching special for baguette and hydrated bread. East and quick change of the belts. Max. production per hour 1500 pieces. Weight range 60-1000 g.

Request for a quote

TALLERES ZELAIETA, SL.

Spain

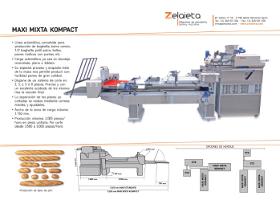

Automatic line, designed to produce baguette, standard bread, 1/2 baguette, small bread, rustic bread with pointed ends, etc. Automatic panning, into a tray, corrugated tray, flat tray or board. Its special process and good treat to the dough, allows to produce high quality bread. It has a cutting system into: 2, 3, 4, 5, or 6 pieces. Accurate and high quality bread after baking. The already cut pieces are separate by some adjustable mobile bands. Width of the loading area: 1150 mm max. Maximum production: 2000 pph individual piece. Cutted pieces: 3500 to 9000 pph.

Request for a quoteResults for

Bakery - Import exportNumber of results

15 ProductsCompany type