- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machines

Results for

Machines - Import export

METMANN

Spain

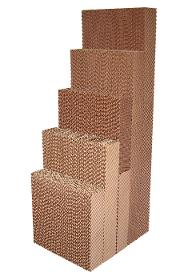

Evaporative cooling panels type 5090 and 7090 PAD MANN evaporative cooling panels are a totally natural air cooling system with water supply and minimum energy consumption. Its operation is based on circulating an air flow through its interior and depending on the speed, type of panel and thickness, the cooling and humidity increase of the air that passes through it is achieved. We have two different types of panels, the type 5090 which is the one that offers the best cooling performance and is used for evaporative coolers for air conditioning in general and the type 7090 with lower cooling performance but with less pressure drop, its Use is specifically for farms and greenhouses where they have evaporative air conditioning systems with fans that cause a depression inside the premises.

Request for a quote

METMANN

Spain

Industrial evaporative air conditioners with axial fan from 10,080 to 19,080 m3/h ECO COOLER evaporative coolers are a natural cooling system that provide cool, humid air in the room to be heated. To cool the air, evaporative cooling technology is used, which consists of passing the outside air through panels moistened with water. As the air passes through this area, it cools and increases its humidity. The treated air is driven by a fan inside the room and by renewing the indoor air comfort temperatures are reached. The necessary electrical power is 80% less than traditional air conditioning systems and by using water as a cooling element it avoids the emission of harmful gases into the environment. ECO COOLER evaporative air conditioners have a 16-speed axial fan to adjust the necessary air flow at all times, they also have an electronic control in charge of performing all the equipment′s functions.

Request for a quote

FORMEX MAQUINARIA

Spain

CHARACTERISTICS OF THE MACHINE -The characteristic of the product, a doughnut with a hole in the centre, requires a distributed dosage in the mould. Each nozzle has a shower-shaped adapter, so that the dose is distributed in the mould. -The dosing nozzles are adapted to the mould dimensions. -Six doughnuts are dosed into each tray. -Smooth conveyor belt on which the silicone trays are manually placed. Guides place the trays in the correct position. -The belt must be kept clean during production, so a scraper is included at the end of the belt to clean any remaining dough. ADVANTAGES -Speed and increase in production, up to six times more. -Uniformity in dosing. -Removable head for complete cleaning and disinfection. We also avoid the staining of the trays and their subsequent cleaning. -The operator places the trays at the beginning of the conveyor and collects them full at the end.

Request for a quote

INDUPLAST PLÁSTICOS DE INGENIERÍA

Spain

Machined parts or 3D additive manufacturing. Adaptable to production lines in the perfumery and cosmetics sector, packaging lines, dispensers and filling. We have a variety of materials and colors, we work with antistatic materials suitable for the sector, we have extensive experience in packaging, as well as special parts for your bottling machinery, maintenance solutions, stands for trade shows, spare parts, etc.

Request for a quote

TRAKTECH

Spain

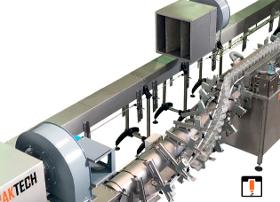

ROTRAK’s monoblock unscrambler and rinser is one of many solutions offered by Trakteck to production companies, integrating two essential elements for the start of bottling lines: A monoblock rotary unscrambler and a rinser, with the aim of supplying empty bottles to the filler. The production company can choose between different positions in the rotating unscrambler and different variants of rinsers developed by Traktech, adapting them to production needs. Integration of Traktech’s bottle unscrambler and the rinser in a single machine allows essential elements to be shared, such as perimeter protection, the electrical panel or the control system. This machine is a useful solution for companies that need to guarantee bottles are well cleaned at the start of the bottling line, before reaching the filler.

Request for a quote

TRAKTECH

Spain

The Rotary Bottle Rinser by TRAKTECH is a compact solution that enables the inside of empty glass, metal or plastic containers to be cleaned, using ionised air, effective for filling lines in companies producing 3,000 – 4,000 bottles per hour (bph). The ingenious input system for containers in the Rotary rinser, that places the empty containers in a vertical carrousel, allows the surface dedicated to cleaning the containers be as small as possible. Production companies maximise productivity of their filling lines per square metre and improve the utility of the production area.

Request for a quote

TRAKTECH

Spain

The Twist Rinser, developed and patented by Traktech, is a system for cleaning the inside of PET (Polyethylene terephthalate) bottles, for companies with lines of high production. It is the only rinser on the market installed on the air conveyor, located between the blower and the filler, significantly reducing production costs and possible incidents in the filling line.

Request for a quote

TRAKTECH

Spain

The Side-Grip Bottle Rinser Machine by Traktech have been developed to guarantee production companies perfect internal cleaning of empty glass, plastic or metal containers, through a dual simultaneous blowing and suction system with ionized air, which with its ion charge, enables air circulation inside the empty containers, expelling all the particles of dirt. The series of Side-Grip rinser can be configured by input and output of empty containers, guaranteeing maximum cleaning.

Request for a quote

REISOPACK S.L.

Spain

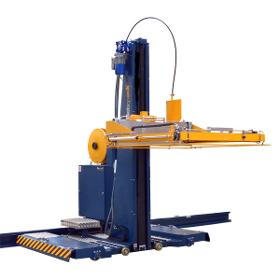

Automatic horizontal strapping machine with lateral displacement. Ideal option to take a leap in productivity in your business. - Own manufacturing and technology using highest quality components. - Compression system in the arch compacts load and guides the strap to the correct position. - Mechanical tension adjustable through a holding strap system to get the highest tension. - Aluminium head Reisopack 1900 long lasting. - Approximate production higher than 50 pallet per hour. - Security system under the arch with reverse engine. - Visual signaling errors. - Touchscreen control 5'6 inch TFT LCD. - Able to store up to 10 different strapping programs.

Request for a quote

REISOPACK S.L.

Spain

Easy to use. The machine can be placed beside the stacked pallet, avoiding the need to move the load. Swappable batteries. - Own manufacturing and technology using highest quality components. - Aluminium head set and tension roller treated ensures long life of the machine. - Tension electronically adjustable through a magnetic clutch to get the strongest tension without any physical effort. - Dual power supply system: To network and with batteries. Removable and interchangeable batteries. - Strapping height manually adjustable without effort. Allows strap from 17 cm. from the floor up to 2 m. - It helps putting edge protectors while first strapping and easy transportation to the place of operation. - Brake lever to prevent unwanted movements. - Bobbin holder located on the base to facilitate bobbin change operation. - Market leader in semiautomatic strapping in fruit and vegetable sector since 1994.

Request for a quote

REISOPACK S.L.

Spain

High performance automatic strapping machine. Very fast. Maximum reliability. - Designed and manufactured using highest quality components. - Aluminium head set and tension roller treated ensures long life of the machine. - Tension electronically adjustable through a magnetic clutch to get the strongest tension without any physical effort. - Electronic control of the tension, heating, cutting and length of the strap. - Adjustment of the cooling after sealing to get better sealing quality, especially for hard packages (wood, iron, etc).

Request for a quote

REISOPACK S.L.

Spain

Automatic machine for the vertical strapping of pallets irrespective of their size. - Our own in-house manufacture and technology using top quality European components. - Aluminium head, tempered tension rollers for longer machine life. - High tension levels achieved through adjustable clip system. - Electronic control of the entire strap tensioning, sealing, cutting and feed process. - Incorporated selector for polypropylene and polyester strapping. - Equipped with seal cooling timer to improve seal quality. - Prepared for integration into fully automatic lines. - Safety standards. CE marking.

Request for a quote

REISOPACK S.L.

Spain

Automatic horizontal strapping machine with lateral displacement. Ideal option to take a leap in productivity in your business. - Own manufacturing and technology using highest quality components. - Compression system in the arch compacts load and guides the strap to the correct position. - Mechanical tension adjustable through a holding strap system to get the highest tension. - Aluminium head Reisopack 1900 long lasting. - Approximate production higher than 50 pallet per hour. - Security system under the arch with reverse engine. - Touchscreen control 5'6 inch TFT LCD. - Able to store up to 10 different strapping programs. - Automatic corners applicator system.

Request for a quote

REISOPACK S.L.

Spain

Automatic horizontal strapping machine with corners applicator system, easy and comfortable to program. Can be integrated into fully automated lines. - Own manufacturing and technology using highest quality components. - Compression system in the arch compacts load and guides the strap to the correct position. - Mechanical tension adjustable through a holding strap system to get the highest tension. - Aluminium head Reisopack 1900 long lasting. - Approximate production higher than 50 pallet per hour. - Security system under the arch with reverse engine. - Visual signaling errors. - Touchscreen control 5'6 inch TFT LCD. - Able to store up to 10 different strapping programs. - Automatic corners applicator system.

Request for a quote

REISOPACK S.L.

Spain

Useful system, simple and easy to program. Suitable for use in fully automated lines. - Own manufacturing and technology using highest quality components. - Compression system in the arch compacts load and guides the strap to the correct position. - Mechanical tension adjustable through a holding strap system to get the highest tension. - Aluminium head Reisopack 1900 long lasting. - Approximate production higher than 60 pallet per hour. - Security system under the arch with reverse engine. - Visual signaling errors. - Touchscreen control 5'6 inch TFT LCD. - Able to store up to 10 different strapping programs. - Can be integrated into a fully automated line.

Request for a quote

FASTENERS AND SPRINGS

Spain

Our most valued asset is, the will and the goal to achieve the unthinkable, as a team that uses traditional methods as well as unconventional ways to achieve what our customer-friends need within the mechanical and humanly possible capabilities. We are able to quote assembly of our springs with your manufactured or out-sourced components, providing value added secondary operations saving you time, freeing up your floor space and in the end saving you money. Our extensive wire inventory and machine capabilities, allow us to handle rush deliveries for various applications and industries, including Defense, Aeronautical, Aerospace or Nautical industries.

Request for a quote

PACKFEEDER

Spain

Either due to the container having handles, serigraphs or simply geometries that make it asymmetrical, the Packfeeder modules provide fast and effective solution to the feeding requirements. The main benefits of the Packfeeder orientation system are: - Simple and efficient operation. - Little additional space required, keeping the feeding and unscrambling of packages unit very compact. - Great ergonomics in its use and maintenance thanks to the modularity in line concept. - Ability to feed packages on a belt or inserted into pucks. - Proven effectiveness in any asymmetric geometry that requires feeding.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STE TECPHARM

Spain

The OPTIMA TABLET COATER is a perforated coating pan designed for the film coating of tablets or pellets, suitable in aqueous and organic coatings, for the pharmaceutical industry. PATENTED COATING TECHNOLOGY THAT INCREASES THE BATCH SIZE RANGE FROM 10% TO 100% AND OPTIMIZES THE PARAMETER ADJUSTMENT FULLY AUTOMATICALLY. Its high technology allows an automatic adjustment control of the flow, avoiding the damp, saving coating and optimizing the processing time. Innovative high-quality equipment certified by accredited entities. Fully designed and built in Europe following regulatory requirements and GMP´s normative. The OPTIMA TABLET COATER controls each critical variable which is decisive for the dynamic equilibrium, such as: ■ Applied liquid flow. ■ Inlet airflow. ■ Exhaust airflow. ■ Inlet and exit air temperature. ■ Tablet temperature during the process. ■ Turning the speed of the pan drum.

Request for a quoteResults for

Machines - Import exportNumber of results

19 ProductsCountries

Company type

Category