- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless steel anchorage

Results for

Stainless steel anchorage - Import export

ABS SAFETY GMBH

Germany

Upgrade your ABS-Lock X anchorage point for usage as a corner or end support in a lifeline system. This additional stainless steel reinforcement (Ø 42 mm) includes an energy absorber and is capable of withstanding the pre-tensioning load exerted on your stainless steel cable. Supporting tube for Ø 16 mm posts Designed for usage as a corner or end support in a lifeline system Includes an energy absorber

Request for a quote

ABS SAFETY GMBH

Germany

To prevent an ABS-Lock III anchorage point from being accidentally bent during the pre-tensioning process, it can be reinforced using one of our specially designed stainless steel ABS-Lock III Supporting Tubes (Ø 42 mm). Simply contact us to check whether your anchorage point can be upgraded prior to installation. Supporting tube for Ø 16 mm posts Designed for usage as a corner or end post in a lifeline system Includes an energy absorber

Request for a quote

ABS SAFETY GMBH

Germany

This high-quality stainless steel cap can be used to hide an ABS-Lock I+II system sleeve that is permanently installed in the subsurface. Not only does it look great - it also protects the sleeve from dust and other contamination. The cap closes automatically, if it is installed on a wall. Protective cap for our ABS-Lock II model High-quality stainless steel material Ø 40mm Closes automatically, if installed on a wall

Request for a quote

ABS SAFETY GMBH

Germany

Install this kind-to-you-roof, stainless steel anchorage point on trapezoidal sheeting using just one single toggle bolt (included). After installation, the supporting rod (Ø 42 mm) fits the opening made in the insulation layer perfectly. EN 795:2012, A + CEN/TS 16415:2017 Trapezoidal sheeting ≤ 0.75 mm Ideal for retrospective installation Installation materials included

Request for a quote

ABS SAFETY GMBH

Germany

The thread (M12) of this particularly robust stainless steel anchorage point is permanently installed in concrete using special adhesive. Once installed, it is suitable for all directions of load. You can install it on the ground, in a wall or overhead, depending on your individual needs. EN 795:2012, A Concrete ≥ C20/25 Recommended accessories: Special Adhesive WIT-VM-250

Request for a quote

ABS SAFETY GMBH

Germany

This easy-to-install stainless steel anchorage point is simply embedded in a concrete surface using a special drive-in dowel (M10). Thanks to its discreet anchorage eyelet, this device, which can be used to secure 1 individual, is virtually indiscernable to the eye following installation. EN 795:2012, A Small and unobtrusive Concrete ≥ C20/25 Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16 mm) for steel surfaces is reinforced through a special supporting tube (Ø 42 mm). You can either use it as a single anchorage point or integrate it into a lifeline system. It is installed laterally using the angular plate supplied and then countered using 2 threaded bolts and corresponding nuts. EN 795:2012, A + CEN/TS 16415:2013 Angular plate for lateral installation Installation materials included

Request for a quote

ABS SAFETY GMBH

Germany

The angular plate supplied with this stainless steel anchorage point (Ø 16 mm) makes light work of installing it on a steel structure. It can be attached to the structure permanently using the 2 threaded bolts included in the package. These are simply inserted through two pre-drilled bores and countered using the nuts supplied. EN 795:2012, A + CEN/TS 16415:2013 Angular plate for lateral installation 2-hole system for flexible installation Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

For a high load-bearing capacity in any direction, simply insert this stainless steel anchorage point (Ø 16 mm) through a pre-drilled hole in a wooden beam and counter it on the other side. This anchor is available with and without a protrusion and can be installed on the ground, laterally or overhead. EN 795:2012, A + EN CEN/TS 16415:2013 Protruding and non-protruding models available Designed for load-bearing wooden structures Minimum rafter dimensions: 100 mm x 120 mm Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

The thread of this no-nonsense stainless steel anchorage point (Ø 16 mm) is screwed straight through the wooden panelling into the beam. Simply drill a hole through the panelling (at least 18 mm) and into a load-bearing wooden beam (min. 80 mm x 120 mm). EN 795:2012, A + CEN/TS 16415:2013 Designed for load-bearing wooden structures Minimum beam dimensions: 80 mm x 120 mm Depth of wooden panelling: ≥ 18mm

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point - which rotates a full 360° - is simply screwed into a pre-drilled threaded bore. It can be installed on steel subsurfaces that are at least 8 mm thick. This anchor, which is suitable for wind turbines (EN 50308), is supplied in yellow. Other colours are available upon request. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2013 EN 50308:2004 (max. 2 individuals) GL-certified 360° rotating eyelet Not suitable for recurrent abseiling usage when installed overhead!

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16 mm), which comes with a base plate (200 x 200 mm), is specially designed to avoid unintentional heat flux. Install this anchorage device in the concrete ceiling of a passive or energy-plus house using the 4 drive-in dowels provided. EN 795:2012, A + CEN/TS 16415:2017 Concrete ≥ C20/25 For roof structures ranging from 150 to 710 mm in depth Thermally insulated thanks to a special spacer Installed using 4x V4A expansion dowels (included)

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point, which comes with a base plate (150 x 150 mm), has been approved by the German Institute for Construction Technology ("DIBt"). It is installed on a steel structure and countered on the other side. The welded-on supporting tube (Ø 42 mm) easily withstands the pre-tensioning stress to which it is subjected when used in a lifeline system. Our standard package includes a set of installation materials. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2017 Base plate + welded-on supporting tube Incl.stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

Particularly robust stainless steel anchorage point with a screw-on supporting tube (Ø 42 mm), base plate (200 x 200 mm) and counter plate (100 x 100 mm). This anchor can be installed in a ceiling, on a facade, on a hollow profile or in lightweight concrete to secure 3 individuals. It can also be implemented as a trouble-free end support in a lifeline system. EN 795:2012, A + CEN/TS 16415:2013 Suitable for installation in a ceiling, on a hollow profile or in lightweight concrete Incl. stainless steel installation set Optional: Installation aid ABS-Lock X-DURCH Sleeve

Request for a quote

ABS SAFETY GMBH

Germany

This reinforced, stainless steel anchorage point - designed for concrete applications - does not create any tension in the substructure and is suitable for unprotected surfaces. It includes a base plate (150 x 150 mm) and a welded-on supporting tube (Ø 42 mm) for extra stability and is installed using the 4 anchor rods supplied. All you need is an installation depth of a mere 60 mm. EN 795:2012, A + CEN/TS 16415:2017 Base plate + welded-on supporting tube Concrete ≥ C20/25 For installation depths ≥ 60mm Recommended accessories: Special Adhesive WIT-VM-250 Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16 mm) - specially designed for flat roofs with a concrete surface - is simply hammered into a clean bore hole. The special, integrated dowel ensures a firm and reliable hold in all directions of load. This anchor has been awarded national technical approval by the German Institute for Construction Technology (DIBt). National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2013 Concrete ≥ C20/25 Installed in just a few minutes Accessories: Stainless steel installation aid to protect the thread

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16 mm) was specially developed with a larger base plate (370 x 370 mm) for installation in lightweight or porous concrete. The 8 anchor rods supplied in the package are cemented permanently into the concrete substructure using special adhesive. EN 795:2012, A + CEN/TS 16415:2013 Porous concrete ≥ P3.3 Add a supporting tube for usage as an end or corner post in a lifeline system Recommended accessories: Special Adhesive WIT-VM-250 Incl. stainless steel installation set

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16mm) and base plate (290 x 200 mm) were developed for usage on a warm roof. The anchor is easily installed from above using the 4 specially prepared toggle bolts included in the package. EN 795:2012, A + CEN/TS 16415:2013 Trapezoidal sheeting (positive/negative), steel ≥ 0.63 mm Warm roofs, distance between the bores: 180 to 250 mm incl. specially prepared toggle bolts Add a supporting tube for usage as an end or corner post in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16 mm) was specially designed for work on solar panels and PV modules. Simply attach the anchor to one of the load-bearing struts of the photovoltaic system using its base and counter plates (100 x 100 mm). EN 795:2012, A + CEN/TS 16415:2017 Suitable for PV and solar panel struts Max. profile dimensions: 50 mm x 50 mm The load-bearing capacity of the supporting substructure must be checked prior to installation! Installation materials included Upgrade with a supporting tube for usage as an end or corner post in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

Install the base plate (200 x 200 mm) of this stainless steel anchorage point (Ø 16 mm) on a load-bearing steel structure and then counter it using 4 stainless steel bolts. This anchor has been awarded national technical approval by the German Institute for Construction Technology ("DIBt"). The bolts and counter nuts required are included in the package. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2013 Incl. stainless steel installation set Upgrade with a supporting tube for usage as an end or corner support in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point, which can be used by one individual for abseiling purposes, comes with an extra-thick base plate (150 x 150 mm) and a welded-on supporting tube (Ø 42 mm). It is simply embedded in concrete using the 4 drive-in dowels supplied. EN 795:2012, A + CEN/TS 16415:2017 Base plate + welded-on supporting tube Designed for C20/25 concrete ≥ 120 mm For installation depths ≥ 70 mm Secures up to 3 individuals Suitable for usage by 1 individual for recurrent abseiling work Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

The round base plate (Ø 400 mm) of this stainless steel anchorage point (Ø 16 mm) guarantees that any force exerted on it is optimally distributed across a thin installation surface. Our standard package includes 24 stainless screws which are used to attach the device to an OSB / wooden surface. EN 795:2012, A + CEN/TS 16415:2013 OSB min. 12 mm Wood min. 18 mm Can also be installed on a vapour barrier or waterproofing (max. 15 mm) Optimal force distribution through the round base plate design Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

The two sides of this stainless steel anchorage point (Ø 16 mm) - specially designed for the roof apex - can be adjusted to the individual pitch of your roof using its adjustable base plate. Our standard package includes 8 stainless steel screws for attaching the device to the rafters. EN 795:2012, A + CEN/TS 16415:2017 Simply screwed onto the roof apex Suitable for usage on both sides of your roof Min. roof rafter dimensions: 80 mm x 120 mm Add a supporting tube for usage as an end or corner post in a lifeline system Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

All you need to install this stainless steel anchorage point (Ø 16 mm), which is suitable for all directions of load, is an installation depth of at least 65 mm. The anchor base plate (200 x 200 mm) is fixed permanently to the concrete subsurface using the 4 drive-in dowels supplied. EN 795:2012, A + CEN/TS 16415:2013 Concrete ≥ C20/25 Installation depth required: Only 65mm Add a supporting tube for usage as an end or corner post in a lifeline system Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

Thanks to its elongated aluminium base plate, this stainless steel anchorage device can be installed on a fibre cement roof (wave distance 177 mm), if the roof beams measure at least 60 x 120 mm. The device is attached to 2 beams. The base plate, which is 125 cm long when delivered, can be shortened onsite, if required. EN 795:2012, A + CEN/TS 16415:2013 Special wave design, e.g. for Eternit and similar roof systems Designed for load-bearing wooden structures Simply screwed onto two adjacent beams Min. beam dimensions: 60 x 120 mm

Request for a quote

ABS SAFETY GMBH

Germany

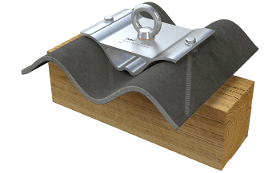

This stainless steel anchorage point is equipped with a wavy aluminium base plate which fits snugly to the waves of a fibre cement roof (wave distance 177 mm). The anchor device is simply screwed onto a wooden beam using the screws provided. EN 795:2012, A + CEN/TS 16415:2013 Special wave design, e.g. for Eternit and similar roof systems Developed for load-bearing wooden structures Simply screw it onto one single wooden beam Min. beam dimensions: 100 x 120 mm

Request for a quote

ABS SAFETY GMBH

Germany

Simply install this stainless steel anchorage point - which includes a welded-on supporting tube (Ø 42 mm) - on a pitched roof surface. The flexible crossbar, which is screwed onto a wooden beam, allows you to adjust it according to the roof pitch. It is installed using the 4 stainless steel screws supplied and then sealed up using a standard antenna tile. EN 795:2012, A + CEN/TS 16415:2013 Designed for load-bearing wooden structures Minimum beam dimensions: 60 mm x 120 mm Adjustable angle and crossbar position Installation materials included

Request for a quote

ABS SAFETY GMBH

Germany

Install this stainless steel anchorage point (Ø 16 mm) - specially-designed for flat roofs (max. 10° pitch) - on bitumen or fabric-reinforced plastic sheeting without penetrating your roof surface - and without the need for extra weights. The crossbars, which are made of high-quality, lightweight aluminium, ensure that the force is reliably distributed whilst keeping the weight down. Meets the requirements of EN 795:2012, A + CEN/TS 16415:2013 Designed for flat roofs with a pitch of up to 10° Min. 15 m² roof space required Fused to a bitumen/fabric-reinforced plastic membrane Penetration-free installation - no extra weights required

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16 mm) has been awarded national technical approval for steel structures. Whatever direction of load is concerned (roof, wall, facade or overhead), it reliably protects your workers from falling . Simply insert the anchor into a pre-drilled bore and counter it using the nut supplied. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2013 Protruding and non-protruding models available Installation materials included Add a supporting tube for usage as a corner or curve element in a lifeline system

Request for a quoteResults for

Stainless steel anchorage - Import exportNumber of results

248 ProductsCountries