- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steam heaters

Results for

Steam heaters - Import export

KLÖPPER-THERM GMBH & CO. KG

Germany

The compact steam superheaters of type series PVN reach high steam temperatures even at low process pressure. Due to the compact design and control concept, they are characterised by short response times, high control precision, and high availability (existing redundancies). In many cases, our steam superheaters are designed as a "stand alone" system and provided completely assembled with all necessary safety devices and controls. The customer must only provide the process connection and the electrical connection.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

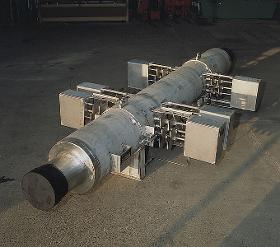

Cable Type Heaters have initially been developed and used for the safe operation in fertilizer plants. However nowadays, they cover a large range of applications due to their modular construction and minimum space requirements. They are suitable for heating up nearly all gases and liquids or superheating steam. They are mainly used in hazardous areas. Especially when processes require a combination of high power (in the MW range) high pressure and temperatures of up to 550°C cable type heaters are the means to choose.

Request for a quote

TMS INDUSTRIAL REFRIGERATION EUROPE B.V.

Netherlands

IRW Water Cooled Type Rooftop units are designed to operate in harsh environmental outdoor conditions by its versatile, efficient and robust characteristics. These units can be used in steel and metallurgy, mining, cement, oil&gas, machinery, energy, marine and defense industries.IRW Water Cooled Type Rooftop units operates with environmentally friendly refrigerants. The air distribution and return are carried out by air ducting which is the best idea for the complex areas to cool down. Various compressor and refrigerant type usages brings trouble-free operation with high cooling water temperatures. Heating can be carried out with electrical heater, steam, hot water and thermal oil resources.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The needs of the power generation industry include year in and year out reliability, optimum performance for maximum efficiency, and absolute on time delivery to meet plant outage schedules. All of the Jet Flow Boiler Feed Water Heaters are designed in accordance with HEI standards, TEMA and ASME codes. Jet Flow uses state of the art computer programs to perform the thermal hydraulic and mechanical design of each Feed Water Heater we fabricate. Jet Flow designs and manufactures both Low Pressure (LP) and High Pressure (HP) feed water heaters which may be installed either vertically or horizontally, depending on the plant design requirements. Each Jet Flow Feed Water Heater will contain from one to three separate heat transfer areas of zones including the Condensing, Desuperheating and Subcooling zones. Our heaters can be provided with multiple zones within the shell side Condensing Zone Included in all heaters,steam is condensed in this zone and non condensable gases are removed.

Request for a quote

STERLING THERMAL TECHNOLOGY LIMITED

United Kingdom

Steam air heaters heat materials, in particular air and liquids. Widely use in dairies for example.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMBIDELUXE GMBH

Germany

Descaler for fully automated coffee machines – 2 x 250ml = 500ml, coffee machines, espresso machines, steam irons, water heaters, natural cleaner with organic acids used universally for Delonghi, Saeco, Tassimo, Senseo, Jura and other brands - Made in Germany - The AmbiClean liquid descaler consists of organic acids that are a 100% naturally degradable. In addition, the descaler contains a red colour indicator that indicates whether the full descaling power is still available. - Descale your equipment regularly to save energy! Limescale deposits cause electrical applicances to use up to 30% more power! - Easy to use and universally used for fully automated coffee machines, coffee machines, espresso machines, steam irons, steam cleaners, water heaters and other equipment. - One bottle is enough for 6 decalcifications. Undiluted, use 125ml per decalcification. Pay attention to the descaling instuctions from your manufacturer. - A quality product which is manufactured in Germany.

Request for a quote

AMBIDELUXE GMBH

Germany

Descaler for fully automated coffee machines – 2 x 750ml (=1.5L), coffee machines, espresso machines, steam irons, water heaters, natural cleaner with organic acids used universally for Delonghi, Saeco, Tassimo, Senseo, Jura and other brands - Made in Germany Environmental friendly: the coffee machine cleaner is made from organic acids, the part of 100% Organic Deconstruct. What's more contains the decalcifier a red colour indicator, indicates whether the the full removing power. A high-quality product: & # X2713 - Original Ambi clean & # X2713 - Made in Germany & # X2713 for more brands such as Jura, Saeco, Melitta, Senseo, etc. & # X2713 ^ Kalk with great protection & # X2713; Easy to use & # X2713; 100% natural & # X2713; 2 bottles (1.5 L) correspond to approx. 12 cleaning processes Energy saving: A scaling also means electronic devices up to 30% more power. Clean your devices regularly to save energy. Avoid unnecessary limescale deposits and trust our organic machine descaler.

Request for a quote

AMBIDELUXE GMBH

Germany

Descaler for fully automated coffee machines – 750ml, coffee machines, espresso machines, steam irons, water heaters, natural cleaner with organic acids used universally for Delonghi, Saeco, Tassimo, Senseo, Jura and other brands - Made in Germany Environmentally Friendly: The coffee machine decalcifier is made entirely out of organic acids that are 100% biodegradable. Additionally, the descaler contains red coloring that indicates whether the liquid is still at maximum strength High Quality Product: ✓ Original AmbiClean ✓ Made in Germany ✓ Designed for many brands including Jura, Saeco, Melitta, Senseo and many more ✓ Optimal Protection against Calcification ✓ Easy to Use ✓ 100% Natural ✓ 1 bottle (750 ml) is enough for 6 cleans. Energy Saving: Calcification induces electronic devices to consume up to 30% more electricity! Clean your equipment regularly to save energy. Avoid unnecessary limescale deposits by trusting in our organic decalcifier.

Request for a quote

LOGISCRAP S.L.

Spain

Commonly called booster module Its function is to CONDITION / PREPARE the fuel before entering the engine Functions: Pressure / Flow / Temperature / Viscosity / Filtration Pumps on one side / Viscosimeter (A) on the other / Filter-s on the other / Heaters on the other. Fuel conditioning is the fuel treatment that is carried out by means of a booster system to comply with the degree of cleanliness, pressure, temperature, viscosity and flow specified by the engine manufacturers. These parameters are vital for the combustion performance of the engine, therefore, adequately protect them is an important part of both the reduction of emissions and energy efficiency. (A) Viscosity control system: Automatically monitors and controls the viscosity of the fuel oil to optimize the burning efficiency of the propulsion systems equipped with HEATPAC electric heaters, steam / thermal oil heaters or conventional capillarity viscometers.

Results for

Steam heaters - Import exportNumber of results

10 ProductsCompany type