- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machinery

Results for

Machinery - Import export

KASAG SWISS AG

Switzerland

Glucose container with fittings for the preparation of glucose (grape sugar) The mobile KASAG glucose container is vacuum-tight and provided with a level detector and pump. Dough container with shredder for the baking industry The dough container with shredder is especially made for the sponge cake industry.

Request for a quote

KASAG SWISS AG

Switzerland

Crèmeur with floor mixing device/anchor mixer and scraper, built on the frame with weighing cells. Net volume, operational requirement can be custom-built. Using the KASAG cheese mixer, the holding capacity can be adjusted to your requirements. The cheese mass can be mixed by means of two counter-rotating spiral conveyors.

Request for a quote

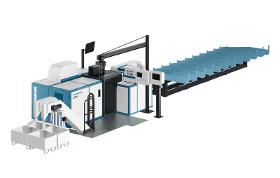

BOGRAMA AG

Switzerland

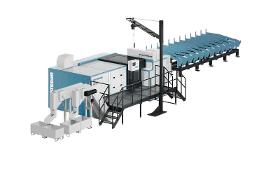

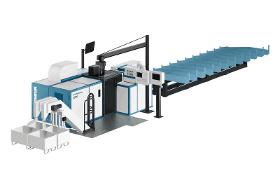

With the new Automated Card Production System for inline die-cutting, collating and stacking of playing cards you can die-cut a wide range of cards including playing cards, gaming cards, trading cards and sports cards and they can be stacked and delivered in one step. The system consists of the market leading BSR 550 Servo rotary die-cutter, feeding into the ACC 550 HS Automatic Card Collator. The cards are die-cut nick-free, stripped out inline, shingled and fed to the ACC 550 HS Card Collator via a conveyor belt. The ACC 550 HS stacks each row into a complete deck and feeds it to a downstream packaging system that may include over wrappers, banding machines, packaging machines or packing table conveyors. With production rates of up to 2,000 decks per hour, the highest quality cutting, makeready times in under 1 hour and an automated delivery that reduces labor to a single person, the BOGRAMA Automated Card Production System has the ROI needed to be the market leader.

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic HM 75 boasts an outstanding concept and is the ideal hotformer for the costefficient production of complex forgings with a diameter of up to 180 mm and an initial weight of up to 7.5 kg. Main advantages Integrated HFE functionality for forwards extruded forgings, Versatile machine kinematics for complex applications, Servohydraulic end stop system for optimal cutoff quality, Lowimpact part discharge reduces the need for remachining, High process reliability thanks to accurate transfer unit with individually monitored grippers

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic HM 35 is the ideal hotformer for the costefficient production of precision forgings with a diameter of up to 75 mm, with a production rate of up to 170 parts per minute. Main advantages Highest productivity in this class, High process reliability, Controlled and lowimpact part discharge, Four forming stations for wide range of applications

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 509 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 108 mm, with a production rate of up to 100 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 509 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 108 mm, with a production rate of up to 100 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 30 S is the ideal hotformer for mediumsized forgings with a diameter of up to 67 mm, with a production rate of up to 140 parts per minute. Main advantages Reliable and durable design, Wide range of uses, Smooth part discharge, High process reliability thanks to servoinfeed and electronic bar end elimination device (ESA 600), Power Failure Protection for high machine safety even during power failures

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 20 S is the ideal hotformer for the costefficient production of high volumes of steel and brass parts with diameters of up to 38 or 42 mm, with a production rate of up to 200 parts per minute. Main advantages Compact design, Easy to operate, High productivity

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 20 N is the ideal hotformer for the costefficient production of forged cam lobes and other challenging forgings with a diameter of up to 48 mm, with a production rate of up to 200 parts per minute. Main advantages High productivity, Lowimpact part discharge, Precise 4roller servoinfeed for challenging parts, Easy to operate

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The COLDmatic CM 45eco is the ideal coldformer for accurate and complex parts from wire, with a production rate of up to 160 parts per minute. It boasts short commissioning times and has a compact design so it takes up less space. Main advantages Easy to operate, Separate lubricant and coolant circuit for maximum tool service life, Very high cutting quality, Accurate parts transport, Versatile kinematics, Optional equipment with heating system, Short commissioning times

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The COLDmatic CM 625 is the ideal coldformer for accurate and complex parts from wire, with a production rate of up to 180 parts per minute. It boasts maximum cutoff quality and userfriendly servo technology in the infeed and transfer unit. Main advantages Short retooling times thanks to innovative servo technology, Easy to operate, Separate lubricant and coolant circuit for maximum tool service life, Very high cutoff quality, Accurate servo linear infeed without bar stop, for defectfree cutoff surfaces, Accurate servo transfer unit for safe part transport, Versatile kinematics, Optional equipment with heating system

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The COLDmatic CM 725 is the ideal coldformer for accurate and complex parts from wire, with a production rate of up to 180 parts per minute. It boasts maximum cutoff quality and userfriendly servo technology in the infeed and transfer unit. Main advantages Short retooling times thanks to innovative servo technology, Easy to operate, Separate lubricant and coolant circuit for maximum tool service life, Very high cutoff quality, Accurate servo linear infeed without bar stop, for defectfree cutoff surfaces, Accurate servo transfer unit for safe part transport, Versatile kinematics, Optional equipment with heating system

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EXXENTIS

Switzerland

Porous aluminium is a high porosity noise insulation material / metal. Silencers made of porous aluminium serve for noise reduction / absorbtion for instance in pneumatic systems. When escaping from the pneumatic device into the atmosphere, compressed air causes noise levels that are unpleasant and unhealthy. This problem is solved if the air leaves the pneumatic device via a silencer/muffler. We are happy to offer you customized silencers in different form and shape according to your needs - cylindical silencers, silencers in plate and discs form, industrial silencers and mufflers for different applications. For the manufacturing of Industrial silencers / mufflers made of porous aluminium we do not use any cost-intensive pressing moulds as sinter technology needs, but conventional casting moulds. Our products made of porous aluminium have – thanks to innovative and relative simple manufacturing technology – an excellent quality-price rati

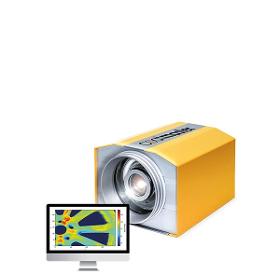

COATMASTER

Switzerland

Decrease setup time for your process. Save material. Document continuously.

Request for a quote

COATMASTER

Switzerland

Just pick it up and start measuring. This handheld is the most innovative one in terms of contactless coating thickness measurement. Would you like to measure the coating thickness early in the process in order to save material and avoid coating mistakes? Then the coatmaster Flex is the right measurement device for you. Optimize your process and get your coatmaster Flex now. If you are not completely satisfied within the first 30 days after delivery, you can return it free of charge.The coatmaster technology (ATO) allows the thickness of the coating to be measured immediately after application. The technology operates contactless and non-destructive without dangerous emissions and is suitable for coating metal, paper, rubber, ceramics, glass, plastic and wood surfaces.

Request for a quoteResults for

Machinery - Import exportNumber of results

21 ProductsCountries

Company type