- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressing

Results for

Pressing - Import export

NOVA WERKE AG - NOVA SWISS

Switzerland

Isostatic presses are specifically developed and manufactured by Nova Swiss Sarl in accordance to customer requirements. Cold, warm and hot presses are available for use at up to 10,000 bar and at temperatures from -20 to 2,200°C. Applications Sintering of powders for the production of complex geometries with high resilience. (Plastic, ceramic, graphite, metal, etc.) Sterilization of food Pressure / temperature simulations Hardening of mechanical parts Elimination of natural porosities in raw metallic materials Pressing of sintered parts (carbides, steels, etc.)

Request for a quote

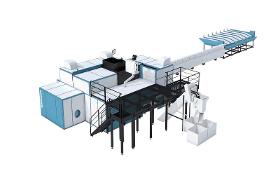

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic HM 35 is the ideal hotformer for the costefficient production of precision forgings with a diameter of up to 75 mm, with a production rate of up to 170 parts per minute. Main advantages Highest productivity in this class, High process reliability, Controlled and lowimpact part discharge, Four forming stations for wide range of applications

Request for a quote

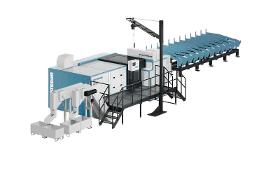

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

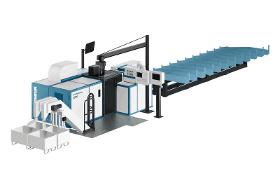

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

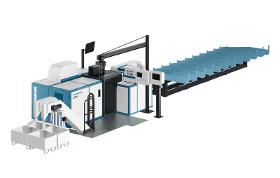

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 509 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 108 mm, with a production rate of up to 100 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 509 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 108 mm, with a production rate of up to 100 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 30 S is the ideal hotformer for mediumsized forgings with a diameter of up to 67 mm, with a production rate of up to 140 parts per minute. Main advantages Reliable and durable design, Wide range of uses, Smooth part discharge, High process reliability thanks to servoinfeed and electronic bar end elimination device (ESA 600), Power Failure Protection for high machine safety even during power failures

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 20 S is the ideal hotformer for the costefficient production of high volumes of steel and brass parts with diameters of up to 38 or 42 mm, with a production rate of up to 200 parts per minute. Main advantages Compact design, Easy to operate, High productivity

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 20 N is the ideal hotformer for the costefficient production of forged cam lobes and other challenging forgings with a diameter of up to 48 mm, with a production rate of up to 200 parts per minute. Main advantages High productivity, Lowimpact part discharge, Precise 4roller servoinfeed for challenging parts, Easy to operate

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The COLDmatic CM 45eco is the ideal coldformer for accurate and complex parts from wire, with a production rate of up to 160 parts per minute. It boasts short commissioning times and has a compact design so it takes up less space. Main advantages Easy to operate, Separate lubricant and coolant circuit for maximum tool service life, Very high cutting quality, Accurate parts transport, Versatile kinematics, Optional equipment with heating system, Short commissioning times

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The COLDmatic CM 625 is the ideal coldformer for accurate and complex parts from wire, with a production rate of up to 180 parts per minute. It boasts maximum cutoff quality and userfriendly servo technology in the infeed and transfer unit. Main advantages Short retooling times thanks to innovative servo technology, Easy to operate, Separate lubricant and coolant circuit for maximum tool service life, Very high cutoff quality, Accurate servo linear infeed without bar stop, for defectfree cutoff surfaces, Accurate servo transfer unit for safe part transport, Versatile kinematics, Optional equipment with heating system

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The COLDmatic CM 725 is the ideal coldformer for accurate and complex parts from wire, with a production rate of up to 180 parts per minute. It boasts maximum cutoff quality and userfriendly servo technology in the infeed and transfer unit. Main advantages Short retooling times thanks to innovative servo technology, Easy to operate, Separate lubricant and coolant circuit for maximum tool service life, Very high cutoff quality, Accurate servo linear infeed without bar stop, for defectfree cutoff surfaces, Accurate servo transfer unit for safe part transport, Versatile kinematics, Optional equipment with heating system

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic HM 75 boasts an outstanding concept and is the ideal hotformer for the costefficient production of complex forgings with a diameter of up to 180 mm and an initial weight of up to 7.5 kg. Main advantages Integrated HFE functionality for forwards extruded forgings, Versatile machine kinematics for complex applications, Servohydraulic end stop system for optimal cutoff quality, Lowimpact part discharge reduces the need for remachining, High process reliability thanks to accurate transfer unit with individually monitored grippers

Request for a quoteResults for

Pressing - Import exportNumber of results

15 ProductsCompany type