- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machines

Results for

Machines - Import export

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom L shape support part is made by material aluminum, turning lathe, milling and colorful anodizing in Taiwan which base on customer’s requirement and meet the ISO certification. Product type:machining parts Product size:30*20*17 mm, as customer’s required Material:aluminum Material available:alloy steel, aluminum, as customer’s required, brass, carbon steel, copper, stainless steel Tolerance:as customer’s required, normally UNI-ISO 2768 Processing:turning lathe, anodizing, milling Surface treatment:anodizing Packing:as customer’s required Measurement:2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application:as customer’s required

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom mounting cape part is made by material aluminum, machining, turning lathe and milling in Taiwan which base on customer’s requirement and meet the ISO certification. Product type: machining parts Product size: dia.40*50 mm, as customer’s required Material: aluminum Material available: alloy steel, aluminum, brass, carbon steel, copper, stainless steel, as customer’s required Tolerance: normally UNI-ISO 2768, as customer’s required Processing: turning lathe, milling Surface treatment: anodizing Other surface treatment Cr-plating, Ni-plating, Tin-plating, Zn-plating, copper-plating, powder coating, as customer’s required Packing: as per customers’ requirement Measurement: 2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application: as customer’s required

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom part is made by material aluminum, turning lathe and colorful anodizing in Taiwan which base on customer’s requirement and meet the ISO certification. Product type: machining parts Product size: dia10*22 mm, dia5*25 mm, dia10*23 mm, as customer’s required Material: aluminum Material available: alloy steel, aluminum, brass, carbon steel, copper, stainless steel, as customer’s required Tolerance: normally UNI-ISO 2768, as customer’s required Processing: turning lathe, colorful anodizing Surface treatment: Cr-plating, Ni-plating, Tin-plating, Zn-plating, copper-plating, powder coating, as customer’s required Packing: as per customers’ requirement Measurement: 2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application: as customer’s required

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom part is made by material aluminum, machining, milling in Taiwan which base on customer’s requirement and meet the ISO certification. Product type: machining parts Product size: dia.30*30 mm, as customer’s required Material: aluminum Material available: alloy steel, aluminum, brass, carbon steel, copper, stainless steel, as customer’s required Tolerance: normally UNI-ISO 2768, as customer’s required Processing: milling Surface treatment: Cr-plating, Ni-plating, Tin-plating, Zn-plating, copper-plating, powder coating, as customer’s required Packing: as per customers’ requirement Measurement: 2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application: as customer’s required

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom shaft part is made by material 304 stainless steel, machining, turning lathe and milling in Taiwan which base on customer’s requirement and meet the ISO certification. Product type: machining parts Product size: dia.40*225 mm, as customer’s required Material: 304 stainless steel Material available: alloy steel, aluminum, brass, carbon steel, copper, stainless steel, as customer’s required Tolerance: normally UNI-ISO 2768, as customer’s required Processing: turning lathe, milling Surface treatment: Cr-plating, Ni-plating, Tin-plating, Zn-plating, copper-plating, powder coating, as customer’s required Packing: as per customers’ requirement Measurement: 2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application: as customer’s required

Do you sell or make similar products?

Sign up to europages and have your products listed

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom mounting cape part is made by material aluminum, machining, turning lathe and milling in Taiwan which base on customer’s requirement and meet the ISO certification. Product type: turning lathe and milling Product size: dia.85*17 mm, as customer’s required Material: aluminum Material available: alloy steel, aluminum, brass, carbon steel, copper, stainless steel, as customer’s required Tolerance: normally UNI-ISO 2768, as customer’s required Processing: turning lathe and milling Surface treatment: anodizing Packing: as per customers’ requirement Measurement: 2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application: as customer’s required

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom housing part is made by material aluminum, machining, turning lathe and milling in Taiwan which base on customer’s requirement and meet the ISO certification. Product type: turning lathe and milling Product size: 115*25*17 mm, as customer’s required Material: aluminum Material available: alloy steel, aluminum, brass, carbon steel, copper, stainless steel, as customer’s required Tolerance: normally UNI-ISO 2768, as customer’s required Processing: turning lathe and milling Surface treatment: Cr-plating, Ni-plating, Tin-plating, Zn-plating, copper-plating, powder coating, as customer’s required Packing: as per customers’ requirement Measurement: 2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application: as customer’s required

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom connection rod part is made by material aluminum, turning lathe, milling and colorful anodizing in Taiwan which base on customer’s requirement and meet the ISO certification. Product type: machining parts Product size: 90*50*20 mm, as customer’s required Material: aluminum Material available: alloy steel, aluminum, brass, carbon steel, copper, stainless steel, as customer’s required Tolerance: normally UNI-ISO 2768, as customer’s required Processing: turning lathe, milling, colorful anodizing Surface treatment: Cr-plating, Ni-plating, Tin-plating, Zn-plating, copper-plating, powder coating, as customer’s required Packing: as per customers’ requirement Measurement: 2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application: as customer’s required

UNITED PROARC CORPORATION

Taiwan R.O.C.

High precision CNC cutting machine 1. Advanced CNC controller - high performance control system 2. High accuracy - ±0.1mm 3. Precision linear way with copper cover for durable lifetime 4. Rigid structure, strong and precision grinding I-rail. 5. Gas control system for Oxyfuel cutting 6. Cutting thickness max. 300mm 7. Durable sealed cable chain for X&Y axes with better protection 8. Applied industries - offshore wind power, steel structure industry, metal processing industry, etc. OPTION : 1. IHT automatic flame cutting torch 2. Plasma / oxyfuel bevel cutting 3. Tube cutting 4. Total cutting solution, includes: -Track foundation (H beam) -Fume extraction table -Dust collector 5. Nesting Software 6. Center drill device 7. LED lamp 8. Anti-spatter spray device *CE Conformity

Request for a quote

BUFFALO MACHINERY CO., LTD.

Taiwan R.O.C.

Standard accessories Spindle oil cooler C-axis Hydraulic 3-jaw chuck Ø52 Chip conveyor Upper and lower turrets Tool setter Robotic arm for parts catcher Heat exchanger Optional accessories Hydraulic 3-jaw chuck Oil skimmer Oil mist collector Air blow device for chuck Parts catcher Coolant cooling-system

Request for a quote

SATIMACO INDUSTRIES CO., LTD.

Taiwan R.O.C.

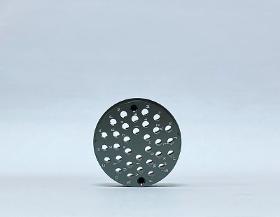

32 holes in 3 steps Optical fiber part OEM and ODM orders are welcome Image for reference of production capability only, product shown is not for sale.

Request for a quote

KOSMOS INDUSTRIES CORPORATION

Taiwan R.O.C.

CNC Milling Parts is the process used to machine both internal bores, profiles & details & also produce external profiles on any component using a variety of specialist tooling. High Quality and manufacturers Experience was Very important and We are proud of our reputation of supplying quality CNC / OEM Equipment and consistently delivering on time. KOSMOS can improve product performance, decrease time to market and lower your manufacturing cost.

Request for a quote

KOSMOS INDUSTRIES CORPORATION

Taiwan R.O.C.

CNC Turning/Lathe machine is a machining/cutting tool which fixed and rotated the raw material rod on it's driving headstock, to remove the material by means of relative movement between various cutting tools and raw material rod. A CNC Turning/Lathe Machine can be combined with specific machining operations, such as turning, threading, boring, drilling, grooving, reaming, cutting, facing, parting, knurling, etc. A CNC Turning/Lathe Machine with computer numerical control(CNC) can be a powerful machine integrated with highly precision CNC control, automatic feeders, coolant systems, translation/rotary systems, etc. KOSMOS Industries Corporation mainly operated with highly precision Japan and Taiwan CNC Turning/Lathe Machining Center, such like Nomura, Star, Moriseiki, Miyano, Takisawa, Chiah Chyun, etc, basically generalized into Fixed Head and Sliding Head Turning/Lathe Machining Centers for various purpose.

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

"Work piece diameter(mm) Ø6 ~ Ø50 Pitch(mm) 0.8P ~ 6.0P, M:0.3 ~ M:1.5 Length of thread rolling(mm) 98MAX Spindle speed 15, 20, 30, 45, 60, 70 r.p.m Thread rolling die(mm) Diameter Ø200MAX Bore Ø70 Length 35,70,100 Keyway 14 X 7 Distance of the rolling spindles(mm) 155 ~ 255 Output (pieces/min) 4 ~ 15 Main power motor 10 HP 6P (7.5 kw) Hydraulic motor 5 HP (3.7 kw) Max rolling pressure 40 TONS Net weight 4050 kgs Gross weight 4450 kgs Overall dimension 1900 x 2300 x 2300 mm Shipping measurement 1800 x 2300 x 2250 mm"

Request for a quoteResults for

Machines - Import exportNumber of results

15 ProductsCountries

Company type