- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermoplastic moulding

Results for

Thermoplastic moulding - Import export

SPIROL

Germany

Heat / Ultrasonic Inserts are designed for post-mould installation in thermoplastics. Heat and ultrasonic installation yield outstanding performance results. SPIROL offers several different series of Heat/Ultrasonic Inserts available in a long and short version of each thread size. Long lengths maximize torque and pull-out resistance, while short lengths are good for less stringent requirements at lower cost and shorter installation times. Some styles are available with or without a head. The head provides bearing surface for the mating component that also prevents jack-out (or when used in reverse, can prevent pull through). However, adding a head results in additional cost raw material of a larger diameter is required to create the head. Some non-headed Inserts are symmetrical – thus eliminating the need to orient the Insert prior to installation.

Request for a quote

BLICKLE RÄDER+ROLLEN GMBH U. CO. KG

Germany

Thermoplastic injection-moulded polyurethane (TPU) based on polyesterpolyol, diisocyanate and glycol. This is vibration-absorbing, non-marking, non-staining and highly abrasion-resistant, while also providing good floor preservation. The tread is also resistant to a wide range of aggressive substances, although it has only limited resistance to hot water or steam.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Occasionally also these terms are used for cartridge heates: heating cartridge, insertion heaters, spiral cartridge heaters. As a rule cartridge heaters consist of a cylindrical stainless steel tube and thus provide a high corrosion prevention. There is a heating wire inside which is wound onto a ceramic core. The number of coils varies depending on the power. In order to avoid a short-circuit, the cartridge heater is filled with magnesium oxide and compressed afterwards. Highly compacted they reach a surface watt density of up to 50 W/cm² and withstand highest stress. In the plastics industry cartridge heaters are used in hot runners in order to temper thermoplasts during injection moulding processes. Other areas of applications for process heat are e. g. packaging, diecasting or continuous casting in which zinc or aluminium are processed. Further applications are to be found in mechanical as well as medical and laboratory engineering.

Request for a quote

HODA, UAB

Lithuania

Gas assist molding is used to hollow out thick sections of a part where coring is not an option and sink is not acceptable. Gas assist molding can be applied to almost any thermoplastic, and most conventional molding machines can be adapted for gas assist molding. One of HODA, UAB activity is the plastic and rubber injection molding, using compressed nitrogen gas. We also provide assembly and packaging services.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

A TECH SUPPLY APS

Denmark

We produce different thermoplastic elastomer and rubber moulded products

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient, practical and functional two working stations injection moulding machine for producing compact, extensive, strong, pliable or unpliable, quality shoe soles in two colours from materials such as TR, TPU, TPE and PVC. The main characteristic of the machine is possessing the PLC control. In the machine are used Siemens products. The operator panel of the PLC appliance is touchscreen what makes the usage of the machine quite comfortable. Heating controls are connected to the PLC device. Injection settings are set from the PLC. A pushing system is available in order to take off the soles from the mold. In the mold rotaion system a fully tumble and half tumble system is available. For each machine's administration, has been placed either hydraulic central or electrical central and the maintenance is done by the easily accessible centrals. Due to the technical characteristics the usage of other machines' molds is possible.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

A press for all processes Beside the pressing systems for industrial production, Siempelkamp manufactures laboratory press systems – both “try-out” presses for laboratoryscale tests with a starting pressing force of 150 t as well as presses for “fullscale testing”. The laboratory press systems are designed for maximum exibility. With it, all processes of composite production can be investigated. For example, it can be investigated whether press technology is an economic alternative for “autoclave” processes. All processes SMC with glass ber or carbon ber RTM PCM Organo-sheet consolidation Thermoplast forming Hybrid forming Integrated molding and joining of hybrid materials All control methods Force control with position monitoring Position control with force monitoring Each process step can be individually dened and programmed: All relevant process data are recorded and displayed.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

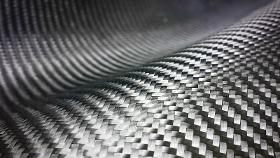

Fiber-reinforced composites are in demand in all high-end industries in which light weight and at the same time high durability under dynamic load ensure competitive advantages Efficient and reliable press technology for fibre composite plants Whether glass fibre reinforced plastic (GRP) or carbon fibre reinforced plastic (CFRP): The valuable material is mainly used in application fields where weight reduction, fuel consumption,anti-corrosion characteristics and other stress resistency feauters are in focus. The name Siempelkamp also stands for solid and precise technologies in these presses and handling systems as well as for high flexibility due to its suitability for all composite applications such as sheet molding compounds with glass or carbon fibers (SMC), prepreg compression molding with short, long or continuous fibers (PCM), resin transfer molding (RTM), and thermoplastic forming.

Request for a quote

DONGGUAN V1 MOLD TECHNOLOGY CO., LTD

China

V1 Mold Technology as a plastic injection molding manufacturer and supplier, specializes in thermoplastic injection molding technology. We've been supplying excellent plastic parts and molds to many of the biggest OEM's 、Tier 1's and Tier 2's automotive manufacturers in the world since 2002. As a reliable partner for automotive molds and parts,we want to deliver the best to our clients and we do this by providing our clients with affordable interior injection molded car components and exterior injection molded car components. Our dedicated automotive teams through design, engineering and manufacturing excellence strive to improve your performance, whatever the part, module, component, sub component or packaging solution you need. Accredited to ISO IATF 16949 our manufacturing plants flexibly adapt their capacities to our automotive customers' needs and requirements.

Request for a quote

HEUTE + COMP. GMBH + CO

Germany

Coatings made of PFA and PVDF fluorine-based thermoplastics provide safe protection against corrosion even on exposure to aggressive media. Because its molecular structure resembles that of PTFE, PFA is almost universally resistant to chemicals. Other special features of PFA linings are their wide range of operating temperatures and easy cleaning due to the material’s non-adhesive nature. In many applications, this makes it possible to replace stainless steel with a raw material which is not only much more economical but also easier to process. Because coatings are applied in a thermoplastic transfer-moulding process, it is necessary to account for certain design aspects which our team will gladly discuss with you in advance.

Request for a quoteResults for

Thermoplastic moulding - Import exportNumber of results

12 ProductsCategory

- Metal industrial presses (2)

- Chemical industry - machinery and equipment (1)

- Electroheat - machines and equipment (1)

- Injection, plastics - machinery (1)

- Plastic products for the vehicle manufacturing industry (1)

- Polyethylene (1)

- Rubber - technical items for industry (1)

- Screw cutting - steels and metals (1)

- Shoes - industrial machinery (1)

- Wheels, castors and rollers (1)