- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tunnel ovens

Results for

Tunnel ovens - Import export

ERATEC

France

Choose our metal fibre burners, choose our infra-red emitter technology for a more efficient, flexible and compact installation. DRYING TUNNELS AND COMBI OVENS For baking, browning, toasting and branding : Biscuits, Bread, Brioche, Toast, Pizza, Pancake, Chips, Chips, Cereals, Meringues... BURNER INTEGRATION EQUIPMENT Deep fryers Kettle Coffee roasting Baking trays Decontamination of cheese crusts

Request for a quote

ERATEC

France

Improve existing equipment by integrating our infra-red emitters, with a positive impact on productivity, quality and energy savings. DRYING TUNNELS AND COMBI OVENS For baking, browning, toasting and marking : Biscuits, Bread, Brioche, Toast, Pizza, Pancake, Chips, Chips, Cereals, Meringues... BURNER INTEGRATION EQUIPMENT Deep fryers Kettle Coffee roasting Baking trays Decontamination of cheese crusts

Request for a quote

ACEMAL NV

Belgium

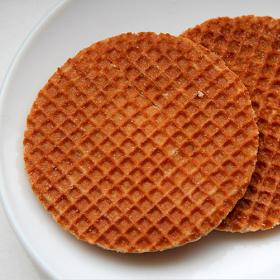

These products are baked through an entirely automated tunnel type oven. Production machines: From 3500 waffles per hour.

Request for a quote

ACEMAL NV

Belgium

These products are baked through an entirely automated tunnel type oven. Production machines: From 3500 waffles per hour.

Request for a quote

ACEMAL NV

Belgium

These products are baked through an entirely automated tunnel type oven. Production machines: From 3500 waffles per hour.

Request for a quote

ACEMAL NV

Belgium

Production machines: Semi-automated or automated production line: Placing of a divider on a TH type oven. On-demand capacity. This type of installation can be automated using a collection robot and a cooling spiral. Automated production line through tunnel oven: From 3500 waffles per hour.

Request for a quote

ACEMAL NV

Belgium

The filling is made after the baking Production machines: These products are baked through an entirely automated tunnel type oven. From 5000 waffles per hour.

Request for a quote

ACEMAL NV

Belgium

The filling is made after the baking Production machines: These products are baked through an entirely automated tunnel type oven. From 5000 waffles per hour.

Request for a quote

ACEMAL NV

Belgium

Tunnel Oven The tunnel ovens allow the cooking of any kind of pastry and are suitable for products like waffles, galettes, pancakes, hotcakes, crackers, etc… They are destined to the production of big capacities. This kind of oven is available in a large range of width and length of cooking allowing a productivity going to 150 000 pieces per hour according the cooking time and the size of the product. TV Oven They are mainly destined to the cooking of soft waffles. This kind of oven is provided with a very precise proportioning system of pastry with a removing system to take out the waffles after their cooking. TH Oven The TH Oven offers the possibility to make several different productions thanks to the interchangeable character of the waffle irons. This oven produces at least 1000 waffles per hour. It can also be equipped with an automatic injection device and with an extraction system. This oven exists in a standard version of 20, 24, 30 or 36 waffle irons. Oven TV-8 New ! Watch t

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

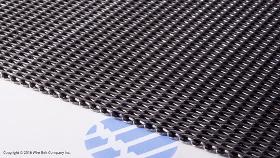

Wire Belt Company’s Rolled Baking Band is designed primarily for ovens common to the baking industry, where an extremely flat carrying surface is required for the direct baking of biscuits and cookies. These belts are often installed in biscuit baking tunnel ovens in lengths in excess of 100 metres with baking zone temperatures up to approximately 310°C.

Request for a quote

EUROLINIA

Belarus

EUROLINIA infrared industrial tunnel ovens are designed to rapidly and uniformly heat the surface of cables, wires, polymer pipes and tubes, dry fiber optics and etc. in batch or continuous conveyor production using targeted high-intensity infrared radiation. High efficiency is achieved by concentrating high-intensity infrared radiation and by using a circular reflector that efficiently distributes radiant energy inside the heating chamber. Additional efficiency is gained by installing three-level thermal protection. EUROLINIA tunnels have modular structure: one heating section is 2 meters long, you can connect up to 8 sections in one production line. Maxumum temperarature in the tunnel can reach up to 700C. Tunnels can have multiple separate heating zones and can be equiped with a conveyor. To ensure high-quality, high-precision surface heating, industrial tunnel ovens are also equipped with an automatic heating control system (APCS).

Request for a quote

PKO-SURA COMPANY

Russia

Bakery tunnel oven is modern equipment designed for baking various confectionery and bakery products on a movable belt (baking plate). We manufacture ovens with various types of conveyors: •wire-mesh conveyor belt (carbon or stainless); •chain conveyor with trays; •slatted conveyor belt with molds; •full metal conveyor belt. •The baking chamber is covered with stainless steel. Increased thermal insulation installed around the baking chamber reduces energy costs.

Request for a quote

PKO-SURA COMPANY

Russia

The СУРА-СП forming machine is designed for molding sugar cookies onto a belt with a further transportation to a wire-mesh plate of tunnel oven. The forming drum is one of the main units of the forming machine. It is a part of this machine and used for forming one type of cookies that have defined shape and pattern. At the request of the Customer, we can manufacture any number of drums with any pattern and shape of cookies. The patterns and shapes are chosen according to the catalogue.

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Tunnel type ovens are convection ovens which allows to electrostatic powder coated work pieces to be cured usually around at 180-200°C in 10 minutes, are used in the powder coating systems. Curing oven length is calculated according to the conveyor speed in order to achieve polymerization and curing of the work piece quantities per shift. The powder coating ovens are designed by us according to the shape, quantity and weight of the product to be cured. These ovens are conveyorised, product inlet and outlets are opened designed accordint to the biggest work piece sizes. Oven can be designed as a tunnel, U, S or W-shaped according to the biggestt work piece and the work shop sizes. Electricity, liquid or gas fuel is used for heating up the ovens.

Request for a quote

SHANGHAI MARYA PHARMACEUTICAL ENGINEERING AND PROJECT CO., LTD.

United States

The oral liquid filling production line is composed of three equipments: bottle washing machine, tunnel sterilization oven, and oral liquid filling capping machine. It is divided into three working areas: cleaning, drying and sterilizing, filing and capping. Each machine can be used separately or in linkage line. During linked production, it can automatically complete cleaning, preheating, drying and sterilization, cooling, filling, screw (rolling) capping and is suitable for the production of packaging lines for oral liquid bottles and other small-dose solutions in the pharmaceutical, health care, food and other industries

Request for a quote

SHANGHAI MARYA PHARMACEUTICAL ENGINEERING AND PROJECT CO., LTD.

United States

The oral syrup liquid filling capping machine production line is composed of four types of equipment: bottle unscrambler, bottle washing machine, tunnel sterilization oven, and liquid filling and capping machine. Each equipment can also be working independently; It can automatically complete bottle unscrambling, cleaning, pre-heating, sterilization, drying, cooling, filling, screw (rolling) capping, and other processes and is suitable for syrups, tinctures, wines, health products, beverages, sauces and other liquids with different viscosity in the pharmaceutical and food industries packaging line production;

Request for a quote

EKOROAST

Turkey

1.aROASTING LINE COMPONENTS ModelExplanationPiece EKO-‐900Z Elevator (H:2650 mm )1 EKO-‐1202Automatıc Salting Machine1 EKO-‐901Pvc Elevator ( L : 3400 mm )1 EKO-‐500Roasting Machine1 EKO-‐700Salt Sieve1 Our ovens are tunnel types of oven These sorts of ovens are able to roast every kinds of peanut and seed, (groundnut, almond, hazelnut, sunflower seed, pumpkin seed and etc.) -In gas ovens, the gas never contacts with the product and ensures that the product is long-lived. These furnaces have a distinctive feature that can adjust the temperature ratings of each roasting room differently, without losing the flavor and aroma of the products The tape that the product stands on is entirely made of stainless steel. – (AISI 304 CrNi). It is possible to adjust the speed of movement of this band to make the roasted products compatible with the taste of harmony.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FIS MODULAR SYSTEMS LTD.

Russia

The modern plunger (piston) dosing system for liquid confectionery masses (marmalade, jelly, creams, soufflé, hot chocolate, etc.) supports dot depositing and dotted line depositing. It is designed for depositing or pouring into molds and special hollows in products of liquid food masses. IntelleDrop can be used both as a stand-alone module for filling molds with marmalade, decorating cookies, or injecting profiteroles, and as part of the CreaSweet complex with installation on the IntelleBase module. It comes with a binary gelling section. You can use the machine with rotary ovens (and you still can upgrade it to work with a tunnel oven).

Request for a quote

UTF

Ukraine

Capacity: 150-500 kg/h Thickness of product: 1,1-1,8 mm Raw material: flour, semolina, corn flour, bean flour and ect. Energy source for oven: electricity Energy source for fryer: electricity, thermos oil, Key features of the production line: - automatic batching system of raw materials is foreseen - different recipe and color of product - homogeneity of batch - different tastes with different spices - design of lines can be developed according to customer’s production premises Equipment set of the line: - extruder of dough ribbon with distributor - dough rolling machine - stretching device - conveyor with knife mechanism - tunnel oven - cooling conveyor - slicing machine - feeding conveyor - drum for removing crumb and small fraction - fryer - conveyor for oil removal - drum with spices batcher - cooling conveyor - elevator - packing machine

Request for a quote

UTF

Ukraine

Capacity: 100-500 kg/h Quantity of dough layers: up to 288 Raw materials: flour Energy source: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - automatic batching system of raw materials is foreseen - wide varaity of products provided by replacable units of forming machine: feeding liquid filling sprinkling by sugar, sesame, poppy rolling in a roll one- and multiple rolling notching on surface - design of lines can be developed according to customer’s production premises Equipment set of the line: - lamination line with fat extruder - forming line - tunnel oven - conveyors system for cooling and packing

Request for a quote

UTF

Ukraine

Capacity: 300-1200 kg/h Quantity of dough layers: 8-16 Raw materials: flour Energy source: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - proofing of product at proofing chamber for improving quality of products - replaceable drums of forming machine for different kinds and sizes of product - options for additional equipment: automatic dough feeding system into extruder salt sprinkler at the oven entry oil sprinkling on the exit form the oven stackers for staking products in stacks - design of lines can be developed according to customer production premises Equipment set of the line: - dough kneading device - proofing chamber - feeding conveyor - extruder - laminator - three-modular rolling machine - forming machine - tunnel oven - rotary conveyor - cooling conveyor - stacker

Request for a quoteResults for

Tunnel ovens - Import exportNumber of results

22 ProductsCountries

Company type

Category

- Confectionery - machinery and equipment (3)

- Bakery - machinery and equipment (2)

- Bakery ovens (2)

- Food Processing (2)

- Pharmaceutical industry - machinery and equipment (2)

- Bread (1)

- Coating machinery (1)

- Conveyor belts (1)

- Food Industry - Machines & Equipment (1)

- Infrared tubes (1)

- Paint drying ovens (1)

- Roasters, industrial (1)