- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- induction

Results for

Induction - Import export

ENERCON INDUSTRIES LTD

United Kingdom

The Super Seal™ Auto Junior semi-automatic induction cap sealer offers the benefits of high-quality induction sealing to start-up operations, product validation and short production runs. The Enercon hand-held cap sealers deliver reliable, repeatable induction sealing and feature quality aids such as batch counters and no-foil indicators, which are often only found on inline production machines. The quality, reliability, and safety and support of Super Seal™ Auto Junior is the same as our high-volume inline production machines. Our hand-held machines are virtually maintenance free and seal continuously time after time for many years without fault. • Fully adjustable table-top stand • Diameter 20-63 mm • Digital timer • Missing foil indicator • 500W output • Dimensions 17.8mm W x 30.0mm D x 38.0 cm H

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

The Super Seal™ Junior manual induction cap sealer offers the benefits of high-quality induction sealing to start-up operations, product validation and short production runs. The Enercon hand-held cap sealers deliver reliable, repeatable induction sealing and feature quality aids such as batch counters and no-foil indicators, which are often only found on inline production machines. Our unique coil design facilitates the sealing of a wide range of caps including flat, sauce dispensing and conical caps, at diameters from 15 – 150mm. Other hand-held devices will only seal flat caps. The quality, reliability, and safety and support of the Super Seal™ Junior is the same as our high-volume inline production machines. Our hand-held machines are virtually maintenance free and seal continuously time after time for many years without fault. • Handheld and portable • Cap size 15-150 mm • Batch and foil counter • Digital timer • Missing foil indicator • 1KW output

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

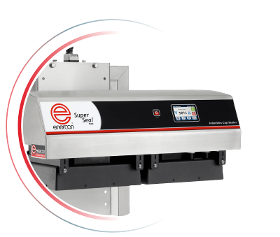

The Super Seal™ Max is the fastest inline sealer on the market, with a dual coil it’s designed for high-speed packaging lines running at up to 100 metres per minute. This dual coil air-cooled induction cap sealer offers increased power and a multi-language touch screen for a simpler operation. It delivers reliable sealing with a diverse operating window that compensates for cap, liner and container tolerance variations. • Multiple language selection • Easy to use touch screen • Supervisory password protection with operator lockout • Recipe management • Internal monitoring of all critical operating data • Container, cap and foil counters available • Local and remote start/stop and power control • Stainless steel IP55 enclosure • Remote network control and monitoring via RS485 or Ethernet • Robust stainless steel fully adjustable stand for different container heights • Seals a variety of caps ranging from 20mm – 150mm • Fully compliant with all CE regulations

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

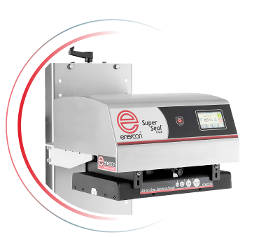

This single coil induction cap sealer offers users increased productivity, an easier set-up and more control. The easy-to-use touch screen is available in multiple languages. The Super Seal™ Touch is our most powerful compact single-coil machine and is designed for production lines running at up to 40 metres per minute. The air-cooled power pack is separate from the induction sealing coil. • Pre-programmed and fully integrated touch screen control for inspection and rejection • Remote start/stop and remote power control (auto start function available) • Password protection with operator lockout • High and low level set power alarm • Recipe management • Internal monitoring of all critical operating data • Diagnostic system information • Internal USB data port – Network connectivity available • Stainless steel IP55 enclosure • Robust stainless steel fully adjustable stand for different container heights • Seals a variety of caps ranging from 20mm – 150mm

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

Many of the issues causing poor seals happen upstream, in the filling or capping area: a seal cannot be achieved with a missing cap or a cap with a missing foil. The capper can also cause stalled bottles under the induction coil where caps are loose or partially fitted or the cap is incorrectly fitted or too high. Issues downstream from the sealer can cause containers to back- up under the sealing head. Enercon produces a range of sensors to help ensure that the sealing process is running faultlessly, producing consistent, reliable seals on every container. • Stalled Bottle and Backlog Detector • Missing Foil Sensor • High Cap Detector • Stack light assembly • Variable Speed Conveyor Systems • Spare Parts Kit • IQ/OQ Kit

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ENERCON INDUSTRIES LTD

United Kingdom

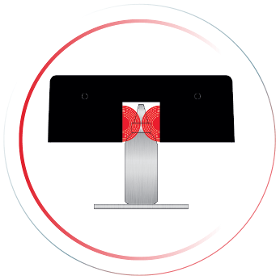

Enercon has two coil design types, each with several variations, to ensure the perfect coil is available for the size and type of your container and cap for your application to deliver perfect, consistent seals. Tunnel coils facilitate higher throughputs than the more traditional flat coils. The Deep Tunnel Coil is used for conical, spouted and other shaped caps. The All-in-One Coil is a variation of the Flat Coil. It is available with the Super Seal™ range and Super Seal™ Touch. This flat sealing head can be pivoted to accommodate various applications. Capable of sealing containers with cap diameters ranging from 20mm to 140mm, it is ideal for packagers who seal a variety of containers and offer the highest degree of sealing versatility. Packagers often don’t realise that the efficiency of the sealing operation depends on the design of the sealing head.

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

The benefits of induction technology in a capless sealing process. Successful sealing on both capless and non-screw-cap containers such as snap on caps is now possible with a pressure Sealer incorporating an Enercon Super Seal™ unit. Typically, pressure belt sealing is used to replace conduction sealing or to reduce the dwell-time needed in conduction sealing. Seals are either placed onto the capless containers or reside in the cap as inserted by the cap manufacturer. The capped container is then guided through the induction heating tunnel, where downward pressure is applied to the clip-on cap or foil by a non-metallic recirculating belt. This unique design automatically takes account of component variations and tolerances, such as bottle height variation, product overfill, line speed variation and bottle centres. Incorporates an Enercon Super Seal™ unit • Cap sizes up to 110mm diameter • Conveyor Speed up to 40 metres / minute

Request for a quote

LMK THERMOSAFE LTD

United Kingdom

For fast, efficient and safe drum heating - a great replacement for old inefficient and expensive steam ovens. Fully ATEX, IECEx and ETL (NA) certified. MELTS SOLIDS ¤ HEATS LIQUIDS ¤ TOTALLY SAFE Designed to heat 205L drums or smaller steel vessels. THERMOSAFE® is a proven alternative to multi-drum ovens and the solution to a host of process heating problems, even in Hazardous Areas SIMPLE SAFE EFFICIENT FAST CLEAN FLEXIBLE MAINTENANCE FREE T: +44 (0)1440 707141 E: sales@drumheating.com

Request for a quote

NARROW AISLE LTD

United Kingdom

Flexi VNA works in just 1.5metre (EURO/ISO 1) or 1.6metre (ISO 2) aisles to BITA GN9 (FEM) standards. 1350kg rated lift capacity and lift heights to over 8.0 metres. Designed to bring Flexi AC articulated space saving and handling efficiency to existing guided VNA warehouses. Operational performance Ultra-narrow 1000mm wide chassis and 220º articulation feature combined with true four-wheel stability for fast, safe operation in the narrowest storage aisles. AC Technology AC technology and four Continental AG MC20 rubber wheels for fast stable operation with low energy consumption and service cost.

Request for a quote

INDUCTION HEATER 4 FLUIDS

United Kingdom

DIFHEMI - EXCLUSIVE AND MULTIFACETED Manufactured by Brascoelma and brought to you by the joint-venture, DIFHEMI heaters are high-technology equipment capable of heating any fluid by electromagnetic induction. The device operates on a different principle because in addition to being versatile, and making it possible to heat any type of fluid, it is non-pollutant, it does not generate useless energy losses, and it reduces operational and implementation costs, the heating process’s performance and efficiency being raised to up to 98%. It is the leader and, worldwide, it is the most-efficient product in existence exploiting the conversion of electrical energy to heat. HOW DO THEY WORK?Employing the principle of electromagnetic induction, DIFHEMI heaters generate heat through the magnetism created in the grain-oriented steel nucleus, the heat being transferred to the stainless-steel tubes through which the fluids circulate.

Request for a quote

INDUCTION HEATER 4 FLUIDS

United Kingdom

Q: What are DIFHEMI inductive fluid heaters? A: DIFHEMI inductive fluid heaters (DIFHEMI is an acronym of ‘direct fluid heating by electromagnetic induction’) are of leading-edge innovative technology which is the sole property of Brascoelma; they belong to a new generation of fluid heaters which are unparalleled worldwide. They are currently the most-efficient equipment and heat any type of fluid, directly or indirectly, liquid or gaseous, at the desired temperature, flow rate and pressure. They utilise electromagnetic induction to generate heat and do not require electrical resistances of any kind, nor the use of fossil fuels. DIFHEMI inductive fluid heaters have permitted realising heating projects which would otherwise be non-viable, and since 1983 over 300 companies have used them. They have been found to be more advantageous than systems utilising resistance heating, fuel oil or natural gas, due principally to the inefficiency inherent in these latter systems of heat generation

Request for a quote

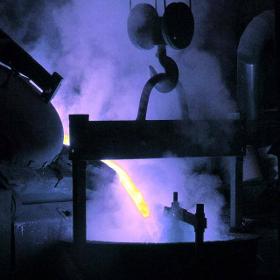

INDUCTION FURNACE SERVICES LIMITED

United Kingdom

Zajmujemy sie naprawami instalacji do wytapiania Inductotherm, usuwaniem wszelakich usterek w jesnostkach mocy VIP. Wykonujemy okresowe przeglady serwisowe. Posiadamy w ofercie szeroki zakres części zamienych. Dojazd do klienta na terenie całej Europy. Krzysztof Kicek Tel. 0044 7726 443392

Request for a quoteResults for

Induction - Import exportNumber of results

13 ProductsCountries

Company type