- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel and metal cutting

Results for

Steel and metal cutting - Import export

1ST MACHINE TOOL ACCESSORIES

United Kingdom

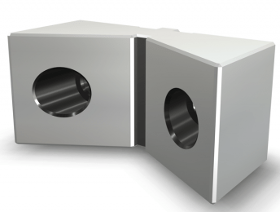

High Accuracy Taper and External Diameter Wide range of Sizes Available These reduction bushes allow for the fitting of boring bars and drills with a tapered shaft. All sizes are manufactured in a range of capacities. The sleeves are hardened and ground for a good fit for both the holder and the shaft.

Request for a quote

ERSEM MECHATRONIC LTD.

United Kingdom

Up to 16mm Carbon Steel, and 4 mm Brass, Copper.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

High Accuracy Taper and External Diameter Wide range of Sizes Available These reduction bushes allow for the fitting of boring bars and drills with a tapered shaft. All sizes are manufactured in a range of capacities. The sleeves are hardened and ground for a good fit for both the holder and the shaft.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

High Accuracy Taper and External Diameter Wide range of Sizes Available These reduction bushes allow for the fitting of boring bars and drills with a tapered shaft. All sizes are manufactured in a range of capacities. The sleeves are hardened and ground for a good fit for both the holder and the shaft.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

High Accuracy Taper and External Diameter Wide range of Sizes Available These reduction bushes allow for the fitting of boring bars and drills with a tapered shaft. All sizes are manufactured in a range of capacities. The sleeves are hardened and ground for a good fit for both the holder and the shaft.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

Our state-of-the-art fibre laser provides you an unprecedented level of freedom in design. Capable of processing tube and box material in varying aluminium, stainless steel and titanium grades and thicknesses. Our laser service provides you with a wealth of new options to consider. As an All-In-One Solution, our laser can do more than just cut material. The laser can implement multiple functions in a single operation, including: cutting, drilling, notching and etching. What once would have taken hours and multiple operations and personnel, now only takes seconds with the help of our friendly Laser Operators, Adrian and Martin. Opposed to traditional cutting methods, laser machines do not require contact upon cutting, -minimising contamination and unwanted marking to the material. When paired with the internal suction probe (more commonly known as “the spoon”), we can produce a final product to a higher standard of finish both in terms of cleanliness and aesthetically.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

Our specialist-built cutting shop is fully equipped to suit your needs. In addition to our laser cutting facilities, we have a bank of fully automatic and semi-automatic cutting machines ready to process materials up to 3,000mm in length. With the capability to hold tight tolerances (+/- 0.20mm) on diameters ranging from 6mm - 153mm, our cutting services are the cost-effective option for high volume repetitive cut orders. Whether you choose the built-in deburring and washing options or the stand alone alternatives available alongside the cutting service, your components will be completed to a high standard of finish.

Request for a quote

PROSAW LIMITED

United Kingdom

This Geka Hydracrop 110S is a versatile and economic universal steelworker with 2 independent hydraulic cylinders, 2 areas and 5 workstations. It is suitable for punching profiles and for mounting special equipment. It benefits from a greater speed backed by a powerful hydraulic unit. Geka Hydracrop 110S Standard Details Machines driven by two cylinders 5 work stations, fitted with tools for L, shearing, round and square bars, rectangular notching and punching Quick change punch Flat bar shearing table with adjustable guides 2 simultaneous work stations Greater speed backed by a powerful hydraulic unit Special equipment for approaching at reduced pressure and slow speed Precision punching table with X & Y measuring stops Precision notching table with X & Y measuring stops Ready for production pack comprising: One meter "touch & cut" length stop with fine adjusting Lamp for enhanced vision of cutting zones 10 sets of round punches and dies

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Adjustable to suit 3 and 4 Segment Collets Used to insert and remove threaded collets. The number of segments the wrench suits can be easily adjusted

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick change jaws for fast setups Hardened and precision ground for wear resistance and accuracy Ideal for demanding clamping conditions and high clamping forces Adapts the OneLok to accept older bolt-on soft jaws Jaw spacers for OneLok that fit 5OL1540 and 5OL1550 and well as the previous generation of OneLok. These jaws are hardened and precision ground for strength and accuracy. The BoltFast mechanism means they can be changed in seconds. The holes in these jaws allow the re-use of standard bolt-on jaws.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Switch between jaws and faceplates in seconds Clamp more complex workpieces Clamp more components at a time Load faceplates outside the machine for better efficiency Faceplates form the base for a fixture to mount directly to the QwikLOK. They are ideal for complex workpieces that cannot be mounted in soft jaws and also allow smaller workpieces to be clamped in larger quantities. Combine a faceplate with simple workstops and clamps to buld a multi component fixture that can be loaded outside the machine. Add another identical faceplate and you have a manual pallet changing system to virtuallly eliminate loading time.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Change jaws in seconds and complete a full setup in a few minutes Precise loction of jaws means your datum is preserved every time you remove the jaws. Once a job is setup, it stays setup. Machinable workholding means complex shaped workpieces are easy to grip Single station jaws can grip larger workpieces with just a quick jaw change Single Station Machinable Jaw Sets increase the flexibility of your system by eliminating the need to completely switch fixtures for jobs requiring greater holding capacity. Simply QwikChange the jaws and the set-up is ready in minutes. These jaws are compatible with 1030 Qwik-loks and 1030 Multi-Loks and are available in a range of sizes. All jaws are available as sets or individually.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

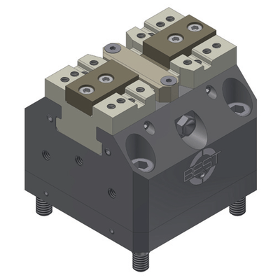

Repetition Accuracy of 5 micron Extremely High Clamp Forces Low wear due to Nitrogen Hardened Surfaces Suitable for Internal or External Clamping BEST hydraulic centric vices are a no compromise solution to repeating and long running 4th and 5th axis workholding. BEST have focused on the production of high accuracy, high rigidity vices. These vices are suitable for both internal and external clamping. They offer very high clamping forces and repeatability of 0.005mm and a centring accuracy of 0.01mm. The Hydraulic vices also have the following options: Clamp Path Monitoring, Fixed Jaw, Central Lubrication System and Positive Air Pressure to prevent swarf ingress.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick Change Mechanism Hardened for Longevity Clamping Surface is Grooved to Avoid Marking Component Custom Sizes Available For clamping workpieces that must not be damaged. The clamping surface is grooved and not ribbed. This results in reducing the potential for marking components. The stepped jaw is hardened approx. 0.2 mm deep. The accuracy of the surface with respect to the serration is +/- 0.02 mm. For greater accuracy, the jaws must be ground in tension on the vice.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick Change Mechanism Hardened for Longevity Gripping Serration is 3mm deep to Reduce Waste Material Requires Low Clamping for during Machining, Reducing Deformation Gripper jaws can reduce the risk of the part being torn out under high machining forces. The penetrating tips produce a very high holding force even at low clamping force.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Aggressive machining operations while clamping on as little as 1.5mm Ideal for difficult applications or proto-type work Jaws to suit round or complex profiles as well as regular shapes Available for 6" and 8" vices Increase the functionality of your standard 150mm and 200mm vices. This combo kit is a simple bolt on system that will allow you to perform aggressive machining operations on Square, round or complex parts while clamping on as little as 1.5mm. This set includes a set of TalonGrip jaws (Sets includes 4 TalonGrips, 1 stop and M5 screws) and a set of VersaGrip jaws (Set includes 4 VersaGrip with M5 Screws).

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Easy machining of round workpieces High precision and high clamping force Wide range of accessories for flexibility Maximise your machining envelope Fixed v-jaws for the SVF range of flexible vices. There are bolt-on hard v-jaws to fit all types of fixed jaw in the SVF range including wedge type and non-wedge type. These v-jaws have a centre key for accurate positioning.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

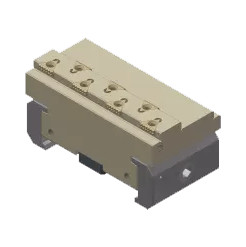

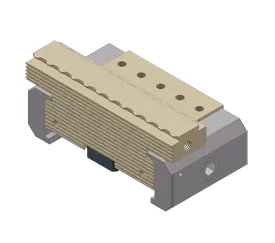

Maximise your machining envelope High precision and high clamping force Wide range of accessories for flexibility Clamp single large or multiple small workpieces Clamps to suit OK-Vise Multi-Rail. Multi-Rail can accommodate OK-Vise clamps, stops, parallels and other accessories to clamp multiple components and maximise your milling work area. All the clamping and location elements on the rail can be positioned according to the size and shape of the workpieces to swiftly adapt from clamping multiple small workpieces to clamping single large workpieces. These clamps are available in a range of styles and applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Maximise your machining envelope High precision and high clamping force Wide range of accessories for flexibility Clamp single large or multiple small workpieces Workstops to suit OK-Vise Multi-Rail. Multi-Rail can accommodate OK-Vise clamps, stops, parallels and other accessories to clamp multiple components and maximise your milling work area. All the clamping and location elements on the rail can be positioned according to the size and shape of the workpieces to swiftly adapt from clamping multiple small workpieces to clamping single large workpieces. These stops are available in a range of styles and applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Switch between jaws and faceplates in seconds Clamp more complex workpieces Clamp more components at a time Load faceplates outside the machine for better efficiency Faceplates form the base for a fixture to mount directly to the QwikLOK. They are ideal for complex workpieces that cannot be mounted in soft jaws and also allow smaller workpieces to be clamped in larger quantities. Combine a faceplate with simple workstops and clamps to buld a multi component fixture that can be loaded outside the machine. Add another identical faceplate and you have a manual pallet changing system to virtuallly eliminate loading time.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Change jaws in seconds and complete a full setup in a few minutes Precise loction of jaws means your datum is preserved every time you remove the jaws. Once a job is setup, it stays setup. Two parts in the same space as one. Maximise your working area and optimise the toolpath. Machinable workholding means complex shaped workpieces are easy to grip Fully machinable aluminium jaws for use on either 0520 Qwik-Loks or 0520 Multi-Loks. The Dual Station Machinable Jaw Sets clamp with an equal and opposing inward force, thus eliminating the potential for jaw lift. The safe low profile jaw interface maximizes the amount of machinable area, giving the ability to hold larger parts. These jaw sets are available in standard size or oversize. An additional set of jaws can be created by purchasing an additional fixed jaw and reversing the movable jaws. All jaws are available as sets or individually.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick change jaws for fast setups Hardened and precision ground for wear resistance and accuracy Ideal for demanding clamping conditions and high clamping forces Plain hard jaws for OneLok that fits 5OL1540 and 5OL1550 and well as the previous generation of OneLok. These jaws are hardened and precision ground for strength and accuracy. The BoltFast mechanism means they can be changed in seconds.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Ideal for Secondary Operations on lathe parts Clamp body made of mild steel for machinability Side screw clamping for blind holes Easily clamped in a lathe chuck The Side-Loc Xpansion Clamp is actuated from the side, making it perfect for blind hole applications. The Side-Loc Xpansion Clamp is designed in two styles, one for milling operations and one for lathe applications. The milling vesrion has a precision machined base for precise location in fixture plates and the lathe version has a 25.4mm shank for gripping in a chuck.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

No need to remove your 3 jaw or collet chuck Side actuated for thru or blind bores Use the same mandrels, sleeves and locators as the hydraulic systems A great option for low/medium-volume production. KEM Series includes a manually-operated expanding mandrel actuator incorporating a precision-ground 38mm diameter spigot for mounting in collet or jaw chucks. These models utilise the same precision mandrels, expanding sleeves and locators as our CNC Expanding Mandrels. They are side-actuated with an included square-drive key so that they can accommodate parts with blind bores as well as those with thru-holes. Precision-ground for high accuracy in squarenesss and concentricity, If higher accuracy is needed the mandrel can be clocked-in once the unit is gripped in a chuck.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems Effectively double the holding capacity of any chuck without eliminating the ability to hold small parts Light-weight 6061 T-6 or 319 for weight saving DESCRIPTION Abbott‘s master plate and segment system is a great choice for turning larger diameter work pieces. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is pre-drilled and keyed to accommodate Abbott’s standard, off-the-shelf segment rings. Plates are available in various diameters from 15 to 60 inches and can be mounted on 8-60 inch diameter chucks, effectively increasing the holding capability of smaller chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size or configuration of segments before continuing

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Universal quick change system for any chuck Repeatability < 0.001" TIR Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems DESCRIPTION When it comes to turning/holding smaller diameter parts Abbott’s precision master plate and segment system is an ideal choice for high changeover and short running jobs. Due to the system’s high repeatability, it is an excellent alternative to more expensive quick change chucks. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is bored and bushed to accommodate Abbott’s standard, off-the-shelf pinned segments. Plates are available in 8, 10 and 12 inch diameters and can be mounted on 4-12 inch diameter chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Universal quick change system for any chuck Repeatability < 0.001" TIR Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems DESCRIPTION When it comes to turning/holding smaller diameter parts Abbott’s precision master plate and segment system is an ideal choice for high changeover and short running jobs. Due to the system’s high repeatability, it is an excellent alternative to more expensive quick change chucks. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is bored and bushed to accommodate Abbott’s standard, off-the-shelf pinned segments. Plates are available in 8, 10 and 12 inch diameters and can be mounted on 4-12 inch diameter chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size or configuration of segments

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems Effectively double the holding capacity of any chuck without eliminating the ability to hold small parts Light-weight 713 Tenzaloy for weight saving DESCRIPTION Abbott‘s master plate and segment system is a great choice for turning larger diameter work pieces. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is pre-drilled and keyed to accommodate Abbott’s standard, off-the-shelf segment rings. Plates are available in various diameters from 15 to 60 inches and can be mounted on 8-60 inch diameter chucks, effectively increasing the holding capability of smaller chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size or configuration of segments

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Centre Cover protects from Swarf Entering Inside the Chuck Replacement dust cover to suit a B series power chuck. The cover plate is used to protect the internal parts of the chuck from swarf ingress.

Request for a quoteResults for

Steel and metal cutting - Import exportNumber of results

34 ProductsCompany type

Category

- Screw cutting - steels and metals (23)

- Cutting - steels and metals (7)

- Pipes and tubes, stainless steel (4)

- Steels and metals - forming and cutting (2)

- Bending - steels and metals (1)

- Perforation of steels and metals (1)

- Laser - cutting and welding machines (1)

- Pipes and tubes - non-ferrous metal (1)

- Shaping - steels and metals (1)