- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum thermoforming

Results for

Vacuum thermoforming - Import export

WESTLAKE PLASTICS EUROPE

France

An innovative techno-material combination for aero / defense / rail parts: With a resin manufacturing partner, Arkema, we have succeeded in extruding sheets in an amorphous state (PEKK material already qualified for aerospace) which crystallizes during thermoforming. The fact that the plates are amorphous allows thermoforming deformation and then crystallization offers all the thermal / mechanical / chemical properties of an ultra high performance polymer. Value proposition: advance in the replacement of metal parts / reduce process costs for machined PEEK parts / open the door to the manufacture of large parts (aircraft interior, drones, defense systems, railways, electrical boxes, ducting systems, etc. )

Request for a quote

BETA PLASTIK VE VAKUM

Turkey

Our company can manufacture various thermoformed ABS plastic parts which our customers require. We can manufacture aluminium mould and after we manufacture ABS sheet by our extrusion line we can thermoformed the plastic sheets. Finally we use our 3-axes and 5- axes CNC machine that trim the products to finalize. Our company working with various company from different sectors. Automative ABS plastic parts,Medical ABS plastic parts etc.

Request for a quote

ARYUSS

Netherlands

PET materials with different thickness are processed with thermoforming methods in automatic machines for different sectors. We are providing 3D designs for new products to our customers. All operations including mould and metallising process are being produced in our company.

Request for a quote

ENOL FOLIEN GMBH

Germany

Top films, bottom films, thermoforming films and vacuum films for meat packaging, sliced meat packaging, cheese packaging etc. High-transparent multi-layer film laminations according to your specifications and requirements as top films, bottom films, thermoforming films as well as vacuum films. We deliver excellent solutions to protect and present your food products. available e.g. in lamination PA – PE – EVOH – PET – PP available as flexible film foil and rigid film Extruded or laminated films for thermoforming process available also as high barrier film with EVOH-coating available also with additional antifog-coating to prevent that the foil gets fogged from inside available also as film with additional UV barrier available also as peelable film (easy to open) available also as numerously resealable film unprinted or printed by flexo printing up to 8 colours or gravure printing up to 10 colours. films available also in dyed execution (different colours possible)

Request for a quote

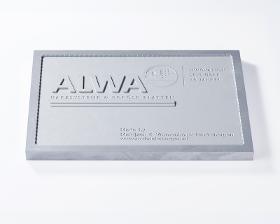

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA POR is porous and has a smooth surface structure. The product is characterized by a high stability, pressure-resistance and a long-term heat resistance of over 190°C. It is especially suitable for moulds with fine and complex structures. The good air permeability leads to a uniform stretching of the foil in the process of thermoforming. With this innovative product the annoying drilling of vacuum holes becomes obsolete and thus no visible markings are left on the thermoformed foil. Larger dimensions can be achieved by screw connections. Longer and wider dimensions by gluing. ALWA POR is easily machinable: Sawing, drilling, grinding, polishing. It also remains porous after polishing. ALWA POR is especially suitable for vacuum thermoforming and vacuum forming and is additionally suitable for - aeration of aquaria, fishponds and sewage treatment plants, - venting of injection moulds and blow moulds, - any proceedings of hot steam or water steam processing, - vacuum clamping

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

MOVE cutlery inserts feature simple no-frills linework and square shapes. The combination of fixed elements and movable dividers within the multi-purpose compartments complements the design and introduces greater flexibility to the organization of kitchen drawers. Modern vacuum thermoforming and tool technology make it possible to control the flow of material in the production process to such an extent that a good material distribution is achieved even when handling highly stretched surfaces. The new styling devoid of radii and graduations harmoniously adapts itself to the design of the drawer guidance systems. As one has come to expect from AGOFORM, every carcase size has its own divisions and variants from 300mm to 1200mm width in two different depths. A sturdy construction coupled with hygienic polystyrene makes for a durable, easy-clean product of the highest quality.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

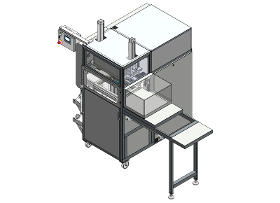

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

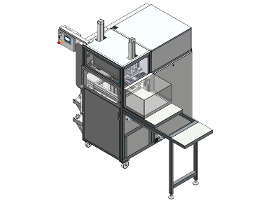

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The automatic continuous stretch vacuum packaging machine is mainly formed by heating and stretching through the lower film, then filling the packaging into the formed lower film cavity, and then entering the heat sealing vacuum chamber to vacuum or inflate the packaging, and put the upper. The film is heat-sealed with the lower film to form a packaging bag, and the packaging is divided by cross-cutting and longitudinal cutting. The finished product output of packaging can be completed automatically at one time, the operation is simple, the labor force is greatly reduced, and the difficulty of recruiting is solved, thereby improving the product quality, beautifying the production environment, improving production efficiency, saving time, labor, and efficiency, etc. Real automation equipment. Application: All kinds of meat,fresh meat, aged meat, sausages, Seafood fish,Dried fruits,Vegetables ,Ready to eat meals,Cheese, Pasta, noodles totally dried cereals, corn kernels, peanuts, etc.

RIDAT

United Kingdom

Ridat Semi Automatic (SA) Vacuum Forming Machines offer, as standard high specifications, consistent production and a wide range of standard models and readiness to respond to requests for bespoke specifications. Fully automatic moulding processing sequences with manual placement of thermoformable sheet and removal of the vacuum formed product. Key machine features include: Ceramic heaters with multi-zone heater control for balanced heat Power assisted and timer controlled heater box movement Hinged clamp frame - powered by two air cylinders Mould chamber fully sealed to maintain vacuum pressure High capacity vacuum reservoir and pump for instant vacuum supply Microprocessor Controls and HMI Display CE Mark

Request for a quote

YENIMAK MAKINA

Turkey

Maximum Mould Size : 650x435mm Maximum Forming Area : 620x405 mm Maximum Cutting Area : 630x405 mm Negative Forming Depth : 120 mm Maximum Sheet Width : 710 mm Minimum Sheet Width : 300 mm Upper Heater Heating Power : 32.5 kW Lower Heater Heating Power : 32.5 kW Continuous Power Consumption : 40 kW Total İnstalled Power : 80 kW Vacuum : 105 m³/h Dry Running Cycle : 60 cycle/min Weight (approx.) : 7000 kg Length : 7000 mm Width : 2300 mm Height : 2500 mm Required Compressor : 3 m³/min Required Cooler : 20000 kcal/hour

YENIMAK MAKINA

Turkey

Maximum Mould Size : 850x650 mm Maximum Forming Area : 820x620 mm Maximum Cutting Area : 820x620 mm Positive Forming Height : 160 mm Negative Forming Depth : 160 mm Maximum Sheet Width : 910 mm Minimum Sheet Width : 400 mm Upper Heater Heating Power : 71 kW Lower Heater Heating Power : 71 kW Continuous Power Consumption : 142 kW Total İnstalled Power : 225 kW Vacuum : 250 m³/h Dry Running Cycle : 60 cycle/dak Weight (approx.) : 14000 kg Length : 10300 mm Width : 2800 mm Height : 3000 mm Required Compressor : 8 m³/min Required Cooler : 50000 kcal

ISIM GELISIYOR CONSULTANCY

Turkey

Our Capabilities in our factory: a. Custom Design and Production: We produce your products labeled with your own LOGO. b. Quality: We always follow the international standardization rules. c. Raw Material: Our company uses high-quality material with various colors such as ABS, PS, PP, APET, PVC, PET, PETG, HIPS, etc. d. Technology: CAD design sketches, custom colors according to international codes. e. Complete Solution: We provide complete solution for your custom design, sample producing, mass production, quality inspection and delivery. f. Generally used but not limited in automotive, medical, food & agricultural machines, advertising tools, yacht & marine, heating & cooling, furniture, toys, packing industries, and all other industrial designs and stands. Industries/Products Automotive, Medical, Food & agricultural machines, Advertising tools, Yacht & marine, Heating & cooling, Furniture, Toys, Packing, Caravan Components, All other industrial designs and stands.

Request for a quoteResults for

Vacuum thermoforming - Import exportNumber of results

14 ProductsCompany type