- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vibrating sieves

Results for

Vibrating sieves - Import export

RUSSELL FINEX LTD

United Kingdom

High-capacity industrial vibrating screens & sieve machines for improving product quality and purity. For more details, please send us a message or click on the website link.

Request for a quote

ROBINSON CO.

Turkey

It is used to separate heavy foreign materials such as stones, glass and metal pieces or soil pieces in the grain with the help of screening method and air. The machine consists of a fixed chassis and vibrating body. The stone separator, designed considering the difference in density of stone and grain, separates the stone by directing the grain in the direction of gravity, in the opposite direction of gravity, with the help of vibration. Wheat is separated from the stones with the help of a vibrating sieve. In addition, dust is absorbed by the air aspiration provided from the ventilation line. Apart from flour and semolina factories, it is also used in all grain factories, vegetable oil factories, cocoa and coffee processing plants.

Request for a quote

ROBINSON CO.

Turkey

It is used to separate heavy foreign materials such as stones, glass and metal pieces or soil pieces in the grain with the help of screening method and air. The machine consists of a fixed chassis and vibrating body. The stone separator, designed considering the difference in density of stone and grain, separates the stone by directing the grain in the direction of gravity, in the opposite direction of gravity, with the help of vibration. Wheat is separated from the stones with the help of a vibrating sieve. In addition, dust is absorbed by the air aspiration provided from the ventilation line. Apart from flour and semolina factories, it is also used in all grain factories, vegetable oil factories, cocoa and coffee processing plants. Application Fields ◾ At food industry ◾ Flour and semolina mills ◾ Cereal cleaning plants ◾ Corn factories ◾ Oil factories ◾ Malt factories ◾ Cacao and coffee plants

Request for a quote

ROBINSON CO.

Turkey

Thanks to the belt-pulley mechanism driven by an electric motor, the rotational motion is transferred to the sieve shaft. The sieve weights, which are placed unbalanced, connected to the sieve shaft, make the sieve vibrate. The position of the screen weights can be adjusted around the screen shaft in order to change the vibration amplitude of the screen. The screen is hung on the ceiling of the place where it is located by means of composite rods in order to create the vibration comfortably. Thanks to this vibration movement, in specially designed sieve boxes, the incoming product is classified and sifted according to its grain size. The product to be screened is sent to the screening area through one or more inlet pipes. Various types of silk-covered cases allow separation in seven channels. This part is directed to the outlet by the channel. After the product is sifted, it is sent to the outlet pipe on the bottom plate. It also has sight pipes for product control and monitoring.

Request for a quote

DRESSLER GROUP

Germany

Method for determining the grain size; air jet sieve, vibrating sieve, but also used in a production system for separating the coarse component of a powder so as to obtain the desired grain size distribution. Using acceleration to separate particles of different weights and therefore mostly different sizes.

Request for a quote

KASAG SWISS AG

Switzerland

The KASAG glove box is used for handling and controlling in sterile processing. The glove box with introducer sheath is equipped with a vibrating sieve and is used when powdery products are filled into bags. The KASAG bag sterilising gassing chamber is used to ensure sterile sealing of products in bags. For that, air is extracted (vacuum) and subsequently swapped with nitrogen. The equipment complies with the strictest hygienic regulations. The mounting can be easily adjusted to the size of the bag.

Request for a quote

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

Using negative air pressure, the Dry Destoner makes the wheat flow on an air cloud. The heavier foreign materials (stones, glass etc.) stay on the vibrating sieve. The sieve acts as an escalator and carries the product to the discharge spout. The machine is driven by two vibration motors. The vibrating body is isolated from the chassis using rubber vibration dampeners and the vibration is isolated. The inclination and air suction level are adjusted for proper cleaning.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

TFBGZ-400 is the pumpkin seeds shelling machine with seed shelling, sorting and shells removing. The processing materials have high commodity are ensured by systematic shelling procedures, screw transportation, efficient de-huller and vibration separating sieve assembly. The production begins with raw materials being fed in the dehuller and then shelled materials, the kernels separate from covers through vibration sieve, and remove broken kernels. Then the shells are removed using cyclone, seeds and kernel fall into second layer of sieve and continue to be screening, kernels come to finished kernel outlet, at same time, secondary shelling for unshelled seeds from procedures. The equipment can be used with the assembly line, increasing production capacity and reducing production costs effectively.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Grain Grade Cleaner is mainly used to sizing the different sizes of seeds, kernels, nuts, beans, etc. Automatic cleaning & grading procedure adopts dual vibrating motors, rubber shock absorber, different sizes of sieves and rubble balls. Materials are vibrated along sieving deck which has multi-layers, then are graded to different levels by size, while oversized and under sized impurities get removed. Customized various screen mesh and amount of sieve layers that make the vibrating grader has wide range of applications and high grading efficiency. Carbon steel or stainless steel can be chosen for quality standard of the screen materials. The product is installed behind the colour sorting machine for a final quality control, or in front of the seeds shelling machine for pre-cleaning. An optimal design, efficient grading operation and compact structure makes it an ideal grading equipment.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Grain Impurity Screen is used for cleaning different size of the impurities in the materials, such as seeds, wheat, nuts, corn, etc. Raw materials after fed into machine by elevator, light impurities and dust were sucked out through double direction of gravity catcher; The left materials enter into vibratory sieving trunk, there are two layers of sieves and the first layer can separate coarse impurities (large pieces of wood, strings and straw) bigger than the grain, while the second layer can separate fine impurities (sand and broken grain) smaller than the grain. The sieves has vibration mechanism to ensure better cleaning process by adjustable angle of engine, and rubber balls inside for the self-cleaning. This product is widely used in agricultural product processing industry of various materials, and it has become the preferred choice for a grain cleaning machine. It can be applied to the assembly line to achieve the automatic work with cyclone dust separator or pulse

Request for a quote

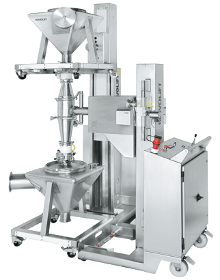

SERVOLIFT GMBH

Germany

The broad applications spectrum of SERVOLIFT milling and sieving equipment leads to flexible and user-friendly solutions in combination with handling systems. The areas of application stretch from controlled sieving in order to remove contamination from raw materials to fractionation, calibration to deagglomeration. Sieve mills, vibration sieve machines or inline sieve equipment in combination with mobile or stationary lifting systems provide a flexible, compact and easy-to-clean system. Size as needed Technical description Stainless steel or cGMP/FDA compliant designs Use as sieve mills (cone mills), hammer mills, oscillating sieve mills Various throughput depending upon the product and particle size Lifting height can be customized Broad control designs, from simple microcontrollers with digital displays to PLC controls Explosion-protected designs in adherence to Atex Zone 1/21 and 2/22.

Request for a quote

SERVOLIFT GMBH

Germany

These types of machines are used for a variety of applications when combined with process machines. The use of cone mills, hammer mills, vibration sieves, sifters, mobile for various areas or stationary. The broad applications spectrum of these devices can be seen in weighing for raw materials preparation or granulation for calibration, to name two examples. The take-up system is designed and adapted depending upon the process machines and the specified runs. Take-up of various additional devices Technical description cGMP-compliant design Mobile or stationary or combinable for high flexibility Adapted take-up system, depending upon the process machines Variable, adjustable lifting function - for mobile units with telescoping designs for low drive-through heights Function extensions through the integration of tilting and pivoting functions Various containment designs, such as low-dust connections up to high-containment solutions Extensive control designs, depending upon...

Request for a quote

NUT TECHNOLOGY

Ukraine

The vibrating sieve is designed for sorting walnut kernels into fractions (sizes) – halves, quarters, eighths of the kernel and crumbs, and at the same time separating the kernel from the shell, partitions and debris. The installation is used in industrial production and processing shops for high-quality and quick sorting of walnuts in large volumes. Advantages of the vibrating sieve with aspiration: Saves time and sorts large volumes of cracked walnuts in a short period of time (up to 300 kg / h). Performs up to 80% of all work on sorting and separating the kernel from the shell. Ensures the smooth operation of production. Reduces the cost of hiring workers – one operator is required to operate the equipment. The platform vibrator provides a constant supply of walnuts from the hopper without manual intervention. Sorting by fractions increases the value of the kernel on the market. Warranty and post-warranty service.

Request for a quote

NUT TECHNOLOGY

Ukraine

The industrial line is a complete range of equipment for processing hazelnuts on a production scale. The line is equipped with such a volume of equipment that will automate your production as much as possible, reduce labor and reduce manual walnut bulkheading to a minimum. Drum nutcracker for hazelnuts is an equipment for high-quality processing of hazelnuts on an industrial scale. The nutcracker provides gentle cracking with maximum whole kernel yield – up to 90%. This model is ideal for use in medium and large enterprises. Nut calibrating machine is intended for sorting hazelnuts in shells into fractions by sizes from small to large for further high-quality and cost-effective processing of hazelnuts on industrial nutcrackers. Calibrator sorts hazelnuts in shell into two sizes. Vibrating sieve and aspiration is designed for screening out shells and dust from the nut kernel and sorting the kernel into fractions.

Request for a quote

NUT TECHNOLOGY

Ukraine

The industrial line is a complete range of equipment for processing almonds on a production scale. The line is equipped with such a volume of equipment that will automate your production as much as possible, reduce labor and reduce manual walnut bulkheading to a minimum. Drum nutcracker for almonds is an equipment for high-quality processing of almonds on an industrial scale. The nutcracker provides gentle cracking with maximum whole kernel yield – up to 90%. This model is ideal for use in medium and large enterprises. Nut calibrating machine is intended for sorting almonds in shells into fractions by sizes from small to large for further high-quality and cost-effective processing of almonds on industrial nutcrackers. Calibrator sorts almonds in shell into two sizes. The vibrating sieve is designed for screening and sorting almonds in the shell according to size.

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

The unique construction of spherical roller bearings make them vital for heavy applications. Their performance is consistent even in extreme conditions, as in the case of high-stress environments and / or reduced lubrication. Spherical roller bearings can give a use life equal to twice that of traditional bearings, according to some estimates. Features of spherical roller bearings: ideal for reduced and medium speeds self-aligning and very robust able to bear radial and axial loads in both directions longer use life compared to traditional bearings excellent compensation for misalignments APPLICATIONS: Earth Moving Machinery Agricultural Machinery Fitness machines Steel working machines Marble processing machines Iron and Steel Industry Oil Industry Automatic opening systems Heavy machinery (eg machines for construction and mining) Bottling / filling carousels Steel mills Industrial transmissions Vibrating equipment / machines Vibrating sieves / vibrating screens

Request for a quote

TAMA AERNOVA SRL

Italy

preventive treatment for the partial demolition of polluting elements in the air The cyclone V- Aren is used as a preventive treatment for the partial demolition of polluting elements in the air. It is suitable for the separation of potentially explosive dusts (ATEX) from coating operations. Benefits The cyclone V - Aren is able to recover over 96% of the input powder using the centrifugal force. The direction of the air outlet is adjustable thanks to a nut installed in the upper part. The V – AREN cyclone dust collector allows the recovery and reuse of the powder by means of a system of automatic sieve located on the discharge of the cone. It is convenient and fast to clean during the color change, easy to carry in a horizontal position and easy to install. Standard equipment V - AREN sieve pneumatic vibrator box commands for opening and closing of the vibrating screen.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Vibrating sieves - Import exportNumber of results

17 ProductsCompany type

Category

- Flour milling - machinery and equipment (4)

- Food canning and preserving - machinery and equipment (3)

- Sorting and sizing equipment for fruits and vegetables (2)

- Bearings - ball, needle and roller (1)

- Food Processing (1)

- Food extracts - machines and equipment (1)

- Mechanical engineering - custom work (1)

- Plastic material processing (1)