- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vices

Results for

Vices - Import export

1ST MACHINE TOOL ACCESSORIES

United Kingdom

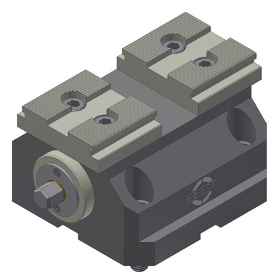

The Chick Workholding System 5 family has evolved through the pursuit of innovation. The range consists of the Qwik-Lok fast-acting vice for vertical CNC machines, and the Multi-Lok for horizontal machine, which is essentially multiple Qwik-Loks placed on the side of a tooling column. Take advantage of the dual station clamping benefits which allow you to present multiple parts to the spindle at once, cutting machine downtime which in turn saves you time and money.

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

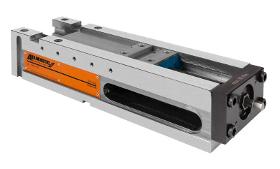

Product features: -Excellent ease of operation guarantees optimal handling for every application -Fast adjustment for clamping range presetting -Reproducible clamping forces are achieved using a torque wrench Integrated scrapers ensure functional reliability and minimise cleaning Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base Optional centre jaw allows two or more workpieces to be clamped Scope of application: -Conventional and CNC-controlled milling machines – for efficient, precision machining -Horizontal installation – great variability and flexibility

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Product features: -Excellent ease of operation guarantees optimal handling for every application -Fast adjustment for clamping range presetting -Reproducible clamping forces are achieved using a torque wrench -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped Scope of application: -Conventional and CNC-controlled milling machines – for efficient, precision machining -Horizontal installation – great variability and flexibility

Request for a quote

PROJECT DRILL

Italy

New factory vice with 270 mm passage Heavy duty vice with extremely robust carpentry Complete with unscrewing cylinder Vice combs with a height of 120 mm Hydraulic cylinders with integrated block valve Suitable to be installed on any type of drilling rig

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

Sterling’s range of bandsaws are one of the leading brands in the metal cutting world. The SRA320 GA CNC series is designed to maximize our customers’ production of heavy metal, profile and pipe cuts in high-volume units with a fully automatic hydraulic feeding system. This a fully automatic machine in a pivot-action design ideally suited for cutting solid material, as well as pipes, profiles and beams in steel cutting. The Omron Touchscreen CNC controller on this saw enables the user to set-up to 30 programmes with 50 steps each for automatic cutting, simply punch in your lengths and quantities, and let the saw do the work for you.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

Sterling’s range of bandsaws are one of the leading brands in the metal cutting world. The SRA320 GA PLC series is designed to maximize our customers’ production of heavy metal, profile and pipe cuts in high-volume units with a fully automatic hydraulic feeding system. This a fully automatic machine in a pivot-action design ideally suited for cutting solid material, as well as pipes, profiles and beams in steel cutting. The Siemens PLC controller on this saw enables the user to set-up a programme with 10 steps for automatic cutting, simply punch in your lengths and quantities, and let the saw do the work for you.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The Bianco AFE CNC Fully Automatic Right Hand Vice Bandsaws 415v are esteemed for their reliability, dependability and high accuracy which are hallmarks of Bianco Bandsaws. Bianco have been manufacturing bandsaws in Italy for over thirty years and have built a reputation for producing precise, reliable, and accurate machines. All machines have modern cast bows from special alloys to ensure one of the highest precision bandsaw ranges available.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The Bianco AF CNC Fully Automatic Right Hand Vice Bandsaws 415v are esteemed for their reliability, dependability and high accuracy which are hallmarks of Bianco Bandsaws. Bianco have been manufacturing bandsaws in Italy for over thirty years and have built a reputation for producing precise, reliable, and accurate machines. All machines have modern cast bows from special alloys to ensure one of the highest precision bandsaw ranges available.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The Bianco AFE Fully Automatic Bandsaws 415v are esteemed for their reliability, dependability and high accuracy which are hallmarks of Bianco Bandsaws. Bianco have been manufacturing bandsaws in Italy for over thirty years and have built a reputation for producing precise, reliable, and accurate machines. All machines have modern cast bows from special alloys to ensure one of the highest precision bandsaw ranges available.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The Bianco AF Fully Automatic Bandsaws 415v are esteemed for their reliability, dependability and high accuracy which are hallmarks of Bianco Bandsaws. Bianco have been manufacturing bandsaws in Italy for over thirty years and have built a reputation for producing precise, reliable, and accurate machines. All machines have modern cast bows from special alloys to ensure one of the highest precision bandsaw ranges available.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

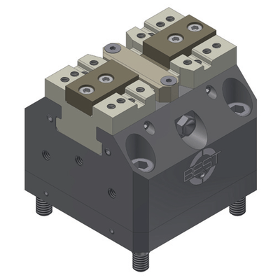

Repetition Accuracy of 5 micron Extremely High Clamp Forces Low wear due to Nitrogen Hardened Surfaces Can be Adapted to suit other manufacturers Zero Point Systems BEST mechanical centric vices are a no compromise solution to varying 4th and 5th axis work. BEST have focused on the production of high accuracy, high rigidity vices. These vices are suitable for both internal and external clamping. They offer very high clamping forces and repeatability of 0.005mm and a centring accuracy of 0.01mm. The machincal vices can be converted to RPCG type to suit the BEST Realpoint Zero Point System The BSMG range have been designed with an enclosed lead screw to reduce maintenance time.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Repetition Accuracy of 5 micron Extremely High Clamp Forces Low wear due to Nitrogen Hardened Surfaces Suitable for Internal or External Clamping BEST hydraulic centric vices are a no compromise solution to repeating and long running 4th and 5th axis workholding. BEST have focused on the production of high accuracy, high rigidity vices. These vices are suitable for both internal and external clamping. They offer very high clamping forces and repeatability of 0.005mm and a centring accuracy of 0.01mm. The Hydraulic vices also have the following options: Clamp Path Monitoring, Fixed Jaw, Central Lubrication System and Positive Air Pressure to prevent swarf ingress.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

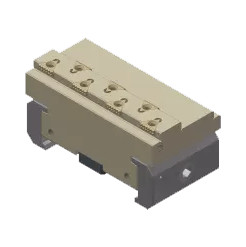

Quick Change Mechanism Hardened for Longevity Clamping Surface is Grooved to Avoid Marking Component Custom Sizes Available For clamping workpieces that must not be damaged. The clamping surface is grooved and not ribbed. This results in reducing the potential for marking components. The stepped jaw is hardened approx. 0.2 mm deep. The accuracy of the surface with respect to the serration is +/- 0.02 mm. For greater accuracy, the jaws must be ground in tension on the vice.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

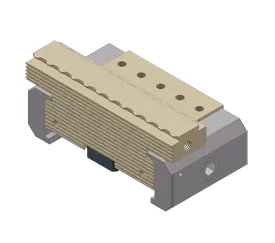

Quick Change Mechanism Hardened for Longevity Gripping Serration is 3mm deep to Reduce Waste Material Requires Low Clamping for during Machining, Reducing Deformation Gripper jaws can reduce the risk of the part being torn out under high machining forces. The penetrating tips produce a very high holding force even at low clamping force.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Easy machining of round workpieces High precision and high clamping force Wide range of accessories for flexibility Maximise your machining envelope Fixed v-jaws for the SVF range of flexible vices. There are bolt-on hard v-jaws to fit all types of fixed jaw in the SVF range including wedge type and non-wedge type. These v-jaws have a centre key for accurate positioning.

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

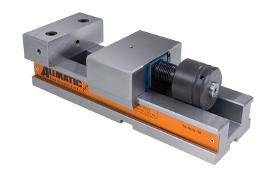

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm Important: -LC 90: drive head with finer clamping force preselection for sensitive workpieces (11 increments)

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability -Particularly suitable for single-piece production if you wish to make your vice rotatable -Can be removed at any time -Swivel base supporting edge larger than the vice‘s maximum clamping range -Swivels 360° without indexing -Alignment on the machine with T-keys in slots in the swivel base -Clamping slots arranged in the form of a ring for machines with different slot spacings

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -For horizontal & vertical usage-suitable for CNC controlled milling machines & large machining centres -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely -Gripper studs suitable for materials with a strength of up toapprox. 1000N/mm² Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models -Fully compatible with the accessories of the LC/TC 160 series, for example gripper studs, universal gripper set & pull down sets -Grounded sides so that all sides can be used High-pressure spindle with mech. force amplifier for the safe clamping of raw parts in combination with gripping & pull down spring function -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -The classical, universal clamp, for vertical 3 axis machining centres -Conventional clamping and gripp clamping possible -Clamping of raw parts, burn and saw cuts by penetrating hardened and interchangeable gripp elements into the workpiece Customer advantages: -Free of charge introduction to gripp technology in comparison to conventional clamping (LC) -First and second clamping stations without retrofitting the step jaws Clamping of raw parts such as burn & saw cuts (materials up to approx. 1000N/mm2) through screwable clamping applications (first clamping station) -Parallel clamping to machined workpieces with the step jaws (2. clamping station) Product features: -The high-pressure spindle allows you to, with a mechanical force amplifier (using the torque wrench), to work and clamp to a table -Stable GGG60 body, grounded top and bottom -Precise tracks in the grounded surface of the soles for optimum alignment on the machining table

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation -Suitable for conventional clamping and for gripper clamping or a combination of both -The support jaws enable a wide range of unmachined parts from flame-cut and sawn materials through to complex castings to be clamped securely and economically. Suitable for materials Product features: -Clamping range adjustment for clamping two workpieces of different sizes -Reproducible clamping forces enable excellent repeating accuracy of the workpiece position -Mechanical power-transfer device -Fully enclosed and maintenance-free high-pressure spindle – high chip protection, minimum cleaning requirements, constant clamping forces up to 40 kN -Use with a torque wrench – max. 40 Nm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm Important: -LC 200: jaw width 200 mm, width of vice base 164 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force - Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Conventional and CNC-controlled milling machines – for efficient precision machining -Horizontal installation – great variability and flexibility Product features : -Excellent ease of operation guarantees optimal handling in every situation -Fast adjustment for clamping range preselection -The clamping force is generated and preset via the hydraulic pressure of a hydraulic unit -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped -Coarse adjustment is performed by turning the spindle. The residual stroke of up to 4.5 mm is performed via a hydraulic unit with spring reset by means of a single-acting cylinder

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Conventional and CNC-controlled milling machines – for efficient precision machining -Horizontal installation – great variability and flexibility Product features : -Excellent ease of operation guarantees optimal handling in every situation -Fast adjustment for clamping range preselection -The clamping force is generated and preset via the hydraulic pressure of a hydraulic unit -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped -Coarse adjustment is performed by turning the spindle. The residual stroke of up to 4.5 mm is performed via a hydraulic unit with spring reset by means of a single-acting cylinder

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal and vertical use - therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, grip clamping and low tension clapping possible -Titanium 2 K - ideal for use on 5-axis machining centers -Clamping of raw, thermal and saw cut parts by penetrating hardened and interchangeable grip elements into the work piece -The support jaws safely and cost effectively allow raw part, different types of materials and complex geometries to be handled Product features: -To monitor and optimize milling processes -Safety for people and machines -High flexibility - the modular clamping system combines almost all possibilities of our tried and tested models -Titanium 2 M - finely polished sides so that all sides can be used -Titanium 2 K and M can be vertically used Force translated high-pressure spindle -Increased power stroke for safe clamping of raw parts -Loss of 8 mm clamping edge in low tension, 3 mm with GRIPP

Request for a quote

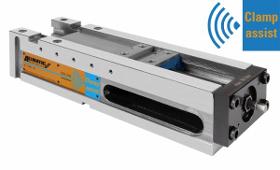

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -For automation of machining centres – particularly suitable for batch production Product features: -Extreme accuracy for your machining -The clamping force is generated via the pressure from a hydraulic unit with a hydraulic clamping stroke of up to 4.5 mm -The clamping force is steplessly adjusted by regulating the hydraulic pressure on the hydraulic unit. A hand crank is provided for coarse adjustment of the clamping range -The spindle contains a single-acting hydraulic piston and an additional Belleville spring assembly

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal & vertical use - therefore suitable for vertical & horizontal CNC milling machines -Conventional clamping, grip clamping and low tension clapping possible -Titanium 2 K - ideal for use on 5-axis machining centers -Clamping of raw, thermal & saw cut parts by penetrating hardened & interchangeable grip elements into the work piece -The support jaws safely & cost effectively allow raw part, different types of materials & complex geometries to be handled Product features: -To monitor & optimize milling processes -Safety for people & machines -High flexibility - the modular clamping system combines almost all possibilities of our tried & tested models -Titanium 2 M - finely polished sides so that all sides can be used -Titanium 2 K and M can be vertically used -Force translated high-pressure spindle. -Increased power stroke for safe clamping of raw parts -Loss of 8 mm clamping edge in low tension, 3 mm with GRIPP

Request for a quoteResults for

Vices - Import exportNumber of results

46 ProductsCountries

Company type