- europages

- >

- Plain bearings

- >

- IGUS® GMBH

- >

- products

IGUS® GMBH - motion plastics® - tech up, cost down!

Germany

Manufacturer/ Producer

IGUS® GMBH

Germany

Solutions for plates Application examples - Automotive The new solution for all applications in stamped sheet metal retainers: iglidur® Clip On's are frequently used in seat and convertible top systems and multi-joint hinges. iglidur® clip-on bearings facilitate captive assembly even in punched sheetmetal / steering arms with limited fine blanking content. Compensation of axial clearance Loss secure pre-assembly possible Electrically conductive materials are optionally available Pressure-resistant materials until 80 MPa The Clip On bearings can also be produced from electrically conducting iglidur® RN89, thus permitting e-coating.

Request for a quote

IGUS® GMBH

Germany

MDM Double flange bearing b1 [mm]: When to use it? When the axial safety of the iglidur® clip bearing is not sufficient When there is a housing with very rough tolerance When high axial forces must be absorbed When not to use it? When an automated assembly is required iglidur® MKM When the iglidur® clip bearings offer adequate tightness iglidur® clip bearing When a large guide length is necessary iglidur® MKM MDM Double flange bearing b1 [mm]: Special features Large flange surfaces Symmetrical flange Easy installation Easy to clip on Undetachable after cataphoretic painting process Special option possible

Request for a quote

IGUS® GMBH

Germany

Special features press fit Both sides axially mounted Tolerance compensation of the sheet thickness Easy installation Axially prestressed Special option possible MKM Double flange bearing d1 [mm]: Special features press fit Both sides axially mounted Tolerance compensation of the sheet thickness Easy installation Axially prestressed Special option possible Press in, flange, finished: loss secure, axially mounted When to use it? When a flanged bearing is needed When the housing bore is more than 4 mm long When the axial safety is not ensured by press fit When a two-side flange is required as a thrust surface When not to use it? When maximum compressive strengths are required iglidur® G When a simple press-in bearing is needed iglidur® M250 When a clip-on sheet metal feedthrough is sought iglidur® G MKM Double flange bearing d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

iglidur® clip bearing, metric d1 [mm]: iglidur® clip bearing, inch d1 [inch]: iglidur® clip bearings are especially intended for the shaft bushing through plates. For this reason the bearing has a flange on each of the two front sides. After the clip-on the bearings are secured on both sides in the plate. The clip bearings have chamfered slot on the side that enables the mounting of the bearing on one side. After the mounting the bearing straddles and lines the bore in the plate. The shaft prevents the clip bearing from slipping out of the bore. The bearing cannot slip out of the bore even in axial movements. Extremely simple mounting through lateral slot Maintenance-free and self-lubricating Good flexibility in punch hole Good abrasion resistance Quiet operation Suitable for rotary and linear movements Extendibility through the slot Undetachable through double flange Special dimensions possible Plate thicknesses from 3 mm to 4 mm available from stock Material: iglidur® M250 Special properties of the iglidur® clip bearings iglidur® clip bearings are made from the most abrasion-resistant material, iglidur® M250. iglidur® M250 is a bearing material for rugged, wear-resistant bearing systems for medium loads. The bearings are self-lubricating and can be used dry. If required the bearings can also be lubricated. The material iglidur® M250 is resistant to all common lubricants. The iglidur® clip bearings are the ideal solution for bearing functions with low loads. The easy mounting makes it ideal for applications with difficult bearing locations. Compressive strength The permitted static surface pressure of iglidur® M250 amounts to 20 MPa at room temperature. Due to the good adaptability to uneven surfaces of the bearing housing, a high pressure load capacity of the clip bearings persists even in punched holes. For the most small bearing surfaces, the good vibration dampening properties and the insensitivity to misalignment are of primary importance. Surface speeds Clip bearings are particularly wear resistant in slow rotating, oscillating and axial motions. You can find the maximum gliding speeds for the various motions for the iglidur® M250 material under the materials data link shown below. A lubrication at installation or continuous lubrication raises the permitted surface speeds. Clip bearings are available from stock in dimensions of 3 to 25 mm. Fixation Triflex RS For mounting, the bearings are laterally pressed together with the large flange. The chamfered slot makes the bearing spiral-shaped, whereby it can be easily inserted in the plate. The remaining slot in the attached clip bearing can compensate for linear expansions of the circumference. Thus narrow bearing clearances are possible with clip bearings. The bearing clearance is dimensioned in such a way that in a housing bore with a nominal diameter, a shaft made with the same nominal diameter turns easily. The clip bearing can be used in H-tolerance housings up to H13. The turning of the clip bearing in the bore is also permitted. Operating temperatures The wear resistance of the iglidur® clip bearings are excellent with operating temperatures till 80°C. Even at low temperature the bearings remain elastic and abrasion resistant. When to use it? When a sheet metal feedthrough is required When the bearing should be captively clipped on in a drill hole with rough tolerance For rotating, linear and pivoting movements When a quick-mounting bearing solution is sought Clip bearings application examples When not to use it? When constant temperatures of more than +80°C occur iglidur® G When a high-precision bearing is needed iglidur® J When the housing bore is more than 4 mm long iglidur® Clips 2 iglidur® MKM When very high surface pressures occur iglidur® G iglidur® clip bearing, metric d1 [mm]: iglidur® clip bearing, inch d1 [inch]:

Request for a quote

IGUS® GMBH

Germany

Special properties: Slewing ring with high stiffening Simple installation, replaceable, maintenance-free sliding elements made of iglidur® J High wear resistance Available as aluminum or stainless steel version V4A (stainless steel only for PRT-01-60 and PRT-01-100) iglidur® PRT slewing ring plain bearing data d [mm]: Special properties: Suitable up to 180°C, high chemical resistance For all 5 standard dimensions of style 01 Body in aluminium or stainless steel, sliding parts in iglidur® H1 d [mm]: Special properties: Free of lubrication and maintenance. For use in extreme dirt. Corrossion-resistant Robust and ready to install Available in dimensions 60 and 100, oneside (-D) or boothside (-DD) seal d [mm]: Special properties: For use in the food industry with gliding elements made of FDA-compliant iglidur® A180 instead of iglidur® J standard. Can be naturally combined with the stainless steel versions of the slewing ring bearing. Lubricant- and maintenance-free For use in extreme dirt. Ready to install Rugged and wear resistant Application areas: Food processing industry d1 [mm]: Special properties: Slewing ring with high stiffening Simple installation, replaceable, maintenance-free sliding elements made of iglidur® J High wear resistance Available as aluminum or stainless steel version V4A (stainless steel only for PRT-01-60 and PRT-01-100) d [mm]: Special properties: Suitable up to 180°C, high chemical resistance For all 5 standard dimensions of style 01 Body in aluminium or stainless steel, sliding parts in iglidur® H1 d [mm]: Special properties: Free of lubrication and maintenance. For use in extreme dirt. Corrossion-resistant Robust and ready to install Available in dimensions 60 and 100, oneside (-D) or boothside (-DD) seal d [mm]: Special properties: For use in the food industry with gliding elements made of FDA-compliant iglidur® A180 instead of iglidur® J standard. Can be naturally combined with the stainless steel versions of the slewing ring bearing. Lubricant- and maintenance-free For use in extreme dirt. Ready to install Rugged and wear resistant Application areas: Food processing industry d1 [mm]: 1 Aluminum, hard anodized 2 iglidur® J sliding elements

Request for a quote

IGUS® GMBH

Germany

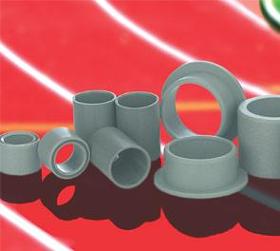

iglidur® C: Free of PTFE and silicon In iglidur® C, the use of Teflon and silicon as lubricants is deliberately avoided. However the bearings display excellent wear resistance at low loads. iglidur® C is available as cylindrical bearings and plain bearings with flange. suitable for dry operation Good abrasion resistance Maintenance-free solution

Request for a quote

IGUS® GMBH

Germany

iglidur® Q: Fit for high load iglidur® Q is the low priced solution for high holding times at high to extreme loads. Bearing made from this material suits all types of movements, but is used preferentially in oscillating motions. iglidur® Q is available as cylindrical bearings, plain bearings with flange and thrust washers. Excellent abrasion resistance, especially with high loads suitable for extreme pv-values Good coefficients of friction Insensitive to dirt

Request for a quote

IGUS® GMBH

Germany

iglidur® B: Highest vibration dampening Vibration dampening is the salient feature of the iglidur® B bearings, which are also well-suited for edge loads at low forces. iglidur® B is available as cylindrical bearings and plain bearings with flange. Sound isolation Extremely high elasticity Sealing function possible

Request for a quote

IGUS® GMBH

Germany

iglidur® J2 Environmentally friendly. The growing demand for PFOA-free iglidur® materials* is met by igus® with an ongoing review of all iglidur® materials – the list of already PFOA-free iglidur® materials is thus getting continuously longer – and a new iglidur® material: iglidur® J2. iglidur® J2 is available as cylindrical bearings and plain bearings with flange. Good mechanical properties, robust Low-priced Good resistance to media Lubricant- and mainteance-free

Request for a quote

IGUS® GMBH

Germany

iglidur® G V0 - polymer plain bearings with UL94 V0 rating V0 classification iaw. UL94, universal. The new material attains the V0 classification in accordance with UL94, making it ideally suited for applications with elevated fire protection requirements (vehicle interiors, aerospace, building technology, etc.). Other properties are similar to our allrounder iglidur® G. Lubricant- and mainteance-free V0 classification pursuant to UL94 high wear-resistance Universal applicability

Request for a quoteManufacturer/ Producer

Spicher Str. 1a

51147 Köln - Germany