JING HENG SING TECHNOLOGY CO., LTD. - FOOD PROCESSING & PACKAGING MACHINERY manufacturers

Taiwan R.O.C.

Manufacturer/ Producer

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

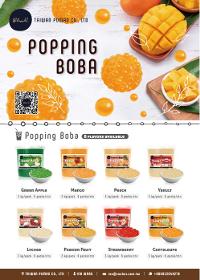

Delight your taste buds with our irresistible popping boba! These delightful bursts of flavor are made with a gel-like shell that encases a burst of fruit juice or flavored syrup. Perfect as a topping or ingredient, our popping boba adds a fun and unique texture to your favorite beverages and desserts. Get ready to experience a burst of flavor with every bite!

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

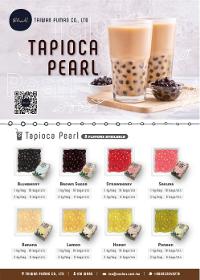

Indulge in the delightful chewiness of our tapioca pearls! Made from cassava root starch, our tapioca pearls are cooked to perfection, resulting in a satisfyingly chewy texture. These versatile pearls are ideal for creating bubble tea, desserts, or adding a unique touch to your favorite beverages. Experience the joy of tapioca pearls and elevate your culinary creations to a whole new level of deliciousness!

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

The screw conveyor conveys the material using the rotation of the screw blade and controls the discharge volume through the size and speed of the screw blade. There are two types of screw conveyor: U-shaped screw conveyor with top cover and tube screw conveyor. The advantage of the screw is that it avoids the dust problems specific to the outlet connected by a closed circuit. It is suitable for conveying various powders. The power end comes with different storage drum options.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

The dust filter is located at the front of the blower, which allows efficient filtration of the air emitted. The filter is equipped with an air purge system that automatically cleans and keeps the filter screen unclogged. The filter area can be manufactured according to customer requirements and is equipped with different types of filters, suitable for different industries and conditions. A manual butterfly valve and a dust container are located under the machine to facilitate cleaning. It is suitable for food, chemical and plastic powders.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

The feeding station (hopper) minimizes dust spillage through the blower and filter stand when manually opening and discharging the bag of material into the production line, thus keeping the working environment clean. Vibrator, filter, magnet, vibrating bridge destroyer, material suction equipment and feeding screw are all optional equipment.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

The centrifugal sieve adopts a drum-shaped sieve structure. The materials are forced through the cyclonic screen by the fan blades rotating at high speed. Materials with desired particle sizes pass through the screen and are collected at the collection conduit. Larger size particles are discharged through the discharge duct to achieve optimum screening effect. The many advantages of the centrifugal screen are the small installation space, effortless ease of maintenance, and quiet operation. The centrifugal sieve is suitable for materials that can be easily agglomerated, such as sugar, cream or high-fat cocoa powder.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

Bulk bag dischargers ensure the smooth discharge of materials. They are divided into the particle type and the powder type dischargers. The bulk bag powder discharger is equipped with a vibrating bridge destroyer and a sealed connection tube to guarantee a dust-free process. Crane or stacker feed are both optional. Bulk bag dischargers are suitable for all kinds of granular or powdery materials such as food or chemicals.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

Ribbon mixer is most suitable for uniformly mixing granular and powdery materials. The spiral twin screw design inside the mixer increases the mixing speed as well as the uniformity of the resulting mixture. The advantages of the ribbon mixer are its economical price and easy maintenance. High consistency uniformity can be achieved in approximately 7-15 minutes per mixing batch. Suitable materials, such as sugar, cream, instant coffee powder or frying powder, etc. can also be fed into the machine via nozzles or via liquid pumps for liquid mixing. Options for combined equipment are pumping systems, weighbridge or powder feeding stations.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

The hammer crusher uses the high rotation speed of rotating blades, which come in different sizes and shapes depending on the type of materials to be crushed. The size of the particles to be obtained can be controlled by changing the mesh of the sieve or by adjusting the speed of rotation of the blades. The advantage of the hammer mill is the low risk of mesh clogging due to the increased screening surface. The hammer crusher is robust, easy to maintain and transportable.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

Apron conveyor is widely used in industry because it works steadily and it is easily cleanable and portable. Covers on both sides of the conveyor ensure there is no material exposure. The overall sizes and angles of the machine are adjustable to suit the designs desired by the customers. Materials in flake or powder form, such as food or chemicals, are best suited for this type of conveyor. Wheels attached to the bottom of the frame provide convenient mobility.

Request for a quoteManufacturer/ Producer

No.346, Sec.5, Dongqi Rd., Dongshi Dist.

423 Taichung - Taiwan R.O.C.