- europages

- >

- Pumps

- >

- KAMAT GMBH & CO. KG

- >

- products

KAMAT GMBH & CO. KG

Germany

Manufacturer/ Producer

KAMAT GMBH & CO. KG

Germany

Extremely high flow rates with the UHD K150000-5G quintuplex plunger pump - ideal for fracking and descaling. With a maximum drive power of 1500 kW, the K150000-5G high pressure pump is an extremely powerful high pressure pump. As a five-cylinder pump (quintuplex), it offers the possibility of pumping without inlet pressure in many applications. Its special five-cylinder design allows large volume flows without cavitation in the pump. Special Features: Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 0-100% depending on rod force dynamically balanced crankshaft Gearbox with external forced lubrication and oil cooling External gear ratios on request e.g. i = 4.76; 5.72; 6.3 Also available to API 674 Horizontal operation Special fluids such as seawater, glycol, methanol, oils, etc. on request.

Request for a quote

KAMAT GMBH & CO. KG

Germany

For special applications, individual high-pressure systems are required, which KAMAT can provide from the initial project idea to the turnkey installation, with 100% of the production taking place in-house. This also applies to electric high-pressure pumping units. Depending on the application, our customers can choose between different drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation equipment. Even the electrical units supplied on the base frame are fully operational and can be used directly by the customer. Electric units have the advantage of emission-free operation at extremely low noise levels. ATEX certified high pressure electric units can also be used in ATEX hazardous areas.

Request for a quote

KAMAT GMBH & CO. KG

Germany

The KamJet is our solution for trouble-free extreme high pressure blasting on a mobile platform. The trailer mounted high pressure unit is powered by a 175kW Volvo diesel engine and produces pressures up to 3,000 bar for up to eight hours on a full tank of fuel. The KamJet mobile high-pressure unit with advanced control unit, optionally suitable for powering the Gekko system. Only high quality parts used - Our KamJet is a complete solution and comes mounted on a twin axle trailer that can travel at speeds of up to 100km/h. All parts and pipework on our units are made from stainless steel. Most importantly, it is equipped with a state of the art control system with touch screen or remote control that fully automatically controls the output pressure and speed. This makes it easy for the user to operate the machine and ensures uninterrupted operation. The KamJet can also be used with two users.

Request for a quote

KAMAT GMBH & CO. KG

Germany

Versatile, turnkey diesel high-pressure pumping units Special applications require customised high-pressure systems, which KAMAT can provide from the initial project idea through to turnkey installation, with 100% of the manufacture taking place in-house. Depending on the application, our customers can choose from a range of drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation. However, the units are ready for use on the base frame on which they are delivered. KAMAT diesel-powered units are traditionally used in industrial cleaning and pressure testing, mining and water hydraulics, but special solutions for special fluids or to meet explosion protection requirements are also part of the KAMAT range. It makes no difference whether the customer requires a mobile or stationary unit.

Request for a quote

KAMAT GMBH & CO. KG

Germany

High-pressure cleaning and surface preparation with water requires precise management of the water jet. This precise management is necessary to ensure that the required result (e.g. surface finish) is achieved within a reasonable time. The method must be safe and fatigue free. With this in mind, we offer a specially designed and manufactured range of high pressure guns with electrical or mechanical control. The exceptional ergonomics of these tools have been achieved through innovative detail solutions: For example, our high-pressure guns are equipped with a special swivel handle that transmits any torque to the wrist. In addition, the hose connection can be swivelled in all directions, allowing optimum hose routing for all working situations. Our range of high pressure guns is complemented by various versions of foot valves, rotating gun lances, rotating nozzles and other accessories for a wide variety of applications, such as pipe cleaning.

Request for a quote

KAMAT GMBH & CO. KG

Germany

Optimum surface cleaning with KAMAT high-pressure rotating nozzles In order to ensure a surface treatment with excellent results and within a reasonable time, we have developed special externally driven rotating nozzles suitable for our high pressure pumps: Depending on the customer's requirements, our nozzles can be driven pneumatically, electrically or hydraulically. With traditional, self-powered rotating nozzles, the water jet hits an angle before it exits the nozzle, causing the nozzle to rotate. Driving the rotating nozzle causes the water jet to lose energy and is therefore much less efficient. Our externally driven rotary nozzles concentrate the hydraulic energy entirely on the machining process. KAMAT rotating nozzles provide coherent jets that can be moved precisely and quickly over large areas. In the case of externally driven rotation, the hydraulic energy is used entirely on the surface being sprayed, giving excellent and efficient results on surfaces.

Request for a quote

KAMAT GMBH & CO. KG

Germany

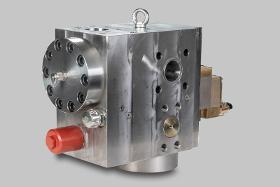

Our valves are manufactured in-house and matched to the characteristics and pressures of your application. Our valves are full lift safety valves and can be spring loaded or pilot operated. All our valves are supplied set to your required working pressure up to a maximum of 4,000 bar and flow rates up to 4,700 l/min. Two versions of spring-loaded safety valves, even ATEX compliant The simpler high pressure valves have a rotatable bypass connection to dispose of leaking fluid. Pilot operated valves require a block flange. Like all other KAMAT products, these are ATEX compliant and can be manufactured in special materials to suit the medium being pumped.

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT pressure relief valves for our high pressure pumps ensure optimum working pressure at all times. They can be configured to control pressure either by mechanical pre-adjustment or by remote pneumatic control. We are also able to manufacture many of our pressure relief valves in special materials, making them ideal for the process industry. In addition, our control rods are made from ceramic or stellite, making all our valves highly wear resistant.

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT's in-house manufactured control valves are the ideal solution when you are looking for a continuous, trouble-free solution for controlling the direction of fluid flow. The combination of our various valves, such as directional, on/off and switching valves, transforms complex tasks into easily controlled functions of your high pressure unit. All of our control solutions can be remotely controlled using either electric, hydraulic, mechanical or pneumatic access, making our solutions even more versatile and adaptable to different demanding environments. All of these solutions can be manufactured using special materials, further enhancing their versatility and making them suitable for use in combination with demanding media such as chemicals.

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT unloading valves are the ideal solution for precise pressure control at fixed or varying volumes. A fast and smooth acting high pressure valve that redirects the flow of the conveyed medium when the desired pressure is reached on the discharge side. Smooth operation makes it a reliable partner for pressure testing pipelines and vessels in all conditions. Reliability is further enhanced by the addition of a surge valve, which is further protected by its own filter. This extra filter is important when solid particles are present in the fluid, such as when drilling mud is reinjected into a well. As well as being reliable, our valves are simple and versatile to control. They can be controlled mechanically, pneumatically, electrically or hydraulically, all with the option of remote control. Special materials can also be used to provide an ideal solution for the process industry.

Request for a quote