- europages

- >

- Gasification - bioenergy systems

- >

- LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN - LIPP System - UNIQUE.WORLDWIDE

Germany

Manufacturer/ Producer

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

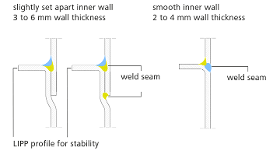

FLEXIBLE, SAFE AND PROVEN THE WORLD OVER – THE LIPP DOUBLE SEAM SYSTEM Conventional systems are often unsuitable for the optimum, safe storage of solid or liquid substances and their use can result in premature corrosion, leaks and problems with safety. Flexibility is another important factor. Tanks must be flexible in terms of size and substrate and optimally adaptable to the local conditions. THE LIPP DOUBLE SEAM SYSTEM HAS PROVEN ITSELF TIME AND TIME AGAIN ALL OVER THE WORLD FOR MORE THAN 45 YEARS MULTI AWARDED. The principle of the LIPP Double Seam System is as follows the edges of steel strips are folded over together twice, connecting them together in such a way that even aggressive liquids inside the tank cannot find any surfaces to attack. The result corrosion is prevented and maximum leak tightness is achieved.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

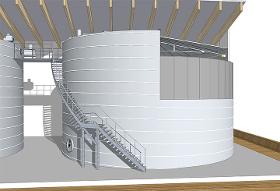

LIPP® Liquid Storage Tanks are fabricated with best material, as this is the most important quality factor. Municipal/industrial waste water and sludge or certain processing, intermediate and end products from the chemical, pharmaceutical and food processing industries set high requirements regarding the tank material, for example. LIPP offers a variety of materials, ranging from galvanised steel through the combination material Verinox to highalloy stainless steels. Variants waste water tanks sewage sludge tanks process water tanks storage tanks firefighting water tanks Mixing and compensation tanks buffer tanks stockable sludge tanks rainwater reservoirs Filtrate water tanks activation tanks Percolating filter tanks Landfill leachate tanks & Special tanks on request

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Special features of the Lipp welding technology are the automated on site construction of above the ground cylindrical tanks made of various grades of duplex steel, stainless steel and black steel. Moreover, the technology also incorporates the post treatment of the weld and a visualized welding monitoring and the technical documentation of the process. Due to the flexible and mobile concept of the equipment, the installation can either be done on greenfield construction sites but also inside buildings or in places with limited access and working space.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The core of the technology is the automated welding process, where the tank is simultaneously welded on the inside and the outside. Similar to the Lipp double fold technology the material will be pre formed by Lipp special forming machines and reinforcement ribs are applied for additional stability. By doing so, the wall thickness can be reduced which will have an economic effect on the overall material costs, without compromising structural stability. The process also enables the installation of roofs and other accessories at ground level, which reduces the risk of working at heights. The main application for the new Lipp welding technology is the drinking water sector. However, there is lots of market potential in the food and beverage industry, chemicals and pharmaceuticals as well as other industries. The black steel welding technology enables the installation of bulk silos with huge diameters and volumes, which is a significant improvement compared to today.

Request for a quoteLIPP GmbH – CONTAINERS AND SYSTEM SOLUTIONS FOR SOLID, LIQUID AND GAS FORMULATIONS. LIPP GmbH in Tannhausen is a specialist for container construction with more than 60 years of experience. We offer you high-quality containers and system solutions made of steel for industry, municipalities and agriculture. Our unique design in the LIPP® system achieves the highest quality. With the focus on durability, flexibility and individual adaptability, we implement your project – from individual containers to turnkey systems. We implement the following products for our customers worldwide: Liquid containers, fermenters, biogas plants, buffer tanks and drinking water reservoirs. Right from the start, attention is paid to the success of the overall result. Suitable materials and high-quality accessories are used to meet the specific requirements of the contents to be stored. With over 200 patents, we have already implemented more than 30, 000 projects worldwide.

Website

Documents

Videos

Manufacturer/ Producer

Industriestrasse 27

73497 Tannhausen - Germany

Company info

Key figures

-

- Company headcount

- 51 – 100

-

- Sales staff

- 1 – 10

-

- % of export sales

- 70%

Organisation

-

- Year established

- 1958

-

- pages.epage-home.site-status

- Registered office

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Delivery areas

Terms of delivery (incoterms)

- Purchaser

- Shared

- Vendor

Activities of LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

- Gasification - bioenergy systems

- Anaerobic processes for biological wastewater treatment

- Stainless steel apparatus and containers

- Containers for wastewater treatment plants

- Fluid containers

- Sewage sludge containers

- Components for biogas plants

- Buffer tank (heat storage tank)

- Steel silos

- Potable water storage tanks