PARSMEGA MAKINA - Agricultural Machines : Flour Milling Machines Manufacturer

Turkey

Manufacturer/ Producer

PARSMEGA MAKINA

Turkey

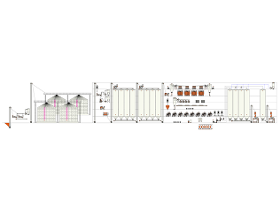

Powering and controlling the motors within the system is done via MCC panels. Contains equipment required for MCC panels, main supply units and remote control. It also has the necessary communication infrastructure for PLC, central automation and SCADA systems. The system automatically protects the motors and all electrical equipment in the field against excessive voltage drops and rises.

Request for a quote

PARSMEGA MAKINA

Turkey

The operating diagram of the system is shown on the small screen It has a healthy compensation system in correct calculations. The panel interior and exterior materials used are in full compliance with the relevant standards and relevant articles. All materials used are fireproof. The system automatically protects the engines and all electrical equipment in the field against excessive voltage drops and rises. All our panel systems are designed so that they can be switched to automation systems in the future. The panels have automatic temperature controlled fans.

Request for a quote

PARSMEGA MAKINA

Turkey

It lightens the load of the rollers and the sieve by breaking the semolina pieces coming from the rollers into very small pieces. The crushing pins on the rotating rotor meet the incoming goods at very high speed and break them. The final product is pushed up from the outlet opening by the centrifugal force created by the high-speed rotating disc.

Request for a quote

PARSMEGA MAKINA

Turkey

It is used to break protrusions in flour factories. Başak, kapçı etc. Used to break protrusions. Machine hammers and fan work coupled to the engine. The broken product is carried to the desired location by the fan. The crusher fan has a maximum sending height of 50 meters. The machine's feeder tank and the cyclone it will use are supplied with the machine. Body thickness is 4 mm, blades are made of special manufacturing steel. The machine is static balanced and operates silently.

Request for a quote

PARSMEGA MAKINA

Turkey

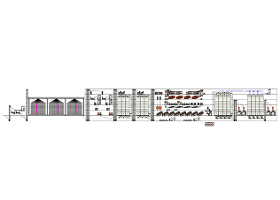

Garbage separator machine is used to separate foreign grain products such as garbage and straw in wheat. The garbage purifier consists of two parts. Upper sieve part: It separates the large foreign substances in the wheat and throws them out. Lower sieve part: It eliminates small foreign substances from the wheat that pass through the upper sieve part and fall on it. Both screen wires can be easily removed and installed by hand. Wheat entering the machine from the product entrance is distributed smoothly and homogeneously on the sieve thanks to the vibromotor mounted on the center of gravity of the machine. The feeding box is oscillated with the body working by vibration on rubber wedges. With an adjustable flap, it ensures that the wheat is distributed across the entire sieve surface.

Request for a quote

PARSMEGA MAKINA

Turkey

It ensures the cleaning of barley, rye, cracked wheat, vetch and black grass seeds in wheat. It performs this cleaning thanks to the sphere-printed sheet metal attached to the body with screws. As this sheet rotates, it separates the materials that will adversely affect the grinding in the incoming product, according to the diameter of the sphere pressure and the spiral angle given by the adjustment lever. The cleaning process takes place at 36 rpm. The trieur machine consists of four main parts, these are: Wheat input Wheat cleaning part Clean wheat output Broken wheat output

Request for a quote

PARSMEGA MAKINA

Turkey

It cleans the stone, soil, all dust particles and bacteria of the wheat with water. It has a double seal device that prevents oil and water from mixing. The entry point of the wheat into the washing tub is moved back and forth to adjust the time the wheat stays in the water. The upper screw rotates rapidly and agitates the water, performing the washing process. Foreign materials (stones, etc.) heavier than wheat sink to the bottom and are thrown out by the gizzard screw rotating in the opposite direction. Light substances such as dust, straw and garbage in the wheat are collected on the surface of the water and thrown out with water through the husk hole. The wheat dragged by the upper screw goes to the vertical drying section working with the centrifugal system. Rapidly rotating pallets in vertical drying throw the product towards

Request for a quote