SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD. - Expertise in Liquid Bottling Equipments

China

Manufacturer/ Producer

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Manual Liquid Piston Filling Machine is suitable for filling small dose viscous liquid , it is adjustable for Cream,sauce,cosmetic Filling, operation by manual power. Filling range from 5ml to 120ml. Feature Reasonable Design: Designed with a high-quality filling head Easy to Operate: Add the filling material to the hopper, adjust the filling volume, then use the handle switch to control and finish the filling. Standard filling nozzles with OD4MM and OD8 mm, suitable for most of the products specification. Comfortable handle which helps improve user more easy operation The filling volume is adjustable by a mechnical screw, easier and faster

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

One of the most significant advantages of an automatic piston filling machine is that it reduces labour costs and increases production speed. The machine can handle a high volume of products, which can help to reduce manufacturing costs in the long term. Furthermore, as the machine is fully automated, it minimises the risk of human error, which further increases production efficiency. Model Recommended: NP-VF 12 Nozzles Servo Piston VolumetricFilling Machine Filling Range: 0.5L- 5L adjustable on touch screen. Bottle Mouth: according to samples Driven and controlled system: Double Panasonic servo motor, one servo motor driven 6 pistons, TBI high precision screw lead, high precision piston. Accuracy: <+/-0.5% Capacity: 3000BPH for 2L

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Easy to install, simple to operate and inexpensive to maintain For different flavor liquids only change the tubes high filling accuracy for small dosing liquid, from 1ml to 100ml is the best filling range if consider both the filling accuracy and speed Servo motor driven, easy adjustable filling volume,more working efficiently

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

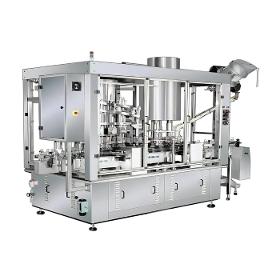

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

For some highly corrosive liquid products, this machine can adapt PTFE pump, PTFE hose and sealing material, so as to avoid the corrosive of the machine 2. The parts in contact with the liquid conform to the GMP standard. When filling, the filling head extends into the bottle and the bottle is sealed to ensure that the liquid does not foam and overflow, and the liquid level in the bottle is consistent. 3. The filling head has the function of sucking back, and there is no dripping phenomenon. The bottle is not in place and not filled, ensuring misoperation and keeping the work area clean. 4. This machine has only one filling pump, one top tank and one side stand tank which can be equipped with 2~20 filling heads, and the output and filling volume can be adjusted if need. More information: When filling, the filling head presses against

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

An automatic detergent piston filling machine is a piece of equipment that is used to fill detergent products into bottles or containers. This machine operates by using a piston that pulls the product from a holding tank and then dispenses it into the containers. The process is automated, which means that the machine can fill a large number of containers quickly and efficiently. Feature: Nozzles Servo Piston VolumetricFilling Machine Filling Range: 0.5L- 5L adjustable on touch screen. Bottle Mouth: according to samples Driven and controlled system: Double Panasonic servo motor, one servo motor driven 6 pistons, TBI high precision screw lead, high precision piston. Accuracy: <+/-0.5% Capacity: 3000BPH for 2L Hopper: automatic liquid feeding system Container: suitable for 0.5-2L Plastic bottles Voltage: 220VAC 50/60Hz Power: 2000W Drop-proof filling nozzles: adapting vacuum sucking nozzles. Touch Screen Language: English and Chinese

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Quantitive the liquid weight by a high quality weigher and weigher sensor High accuracy measurement system for different types of non corrosive liquid, corrosive liquid liquid contact parts 304SS or 316SS depends on the liquid filling volume is easy adjustable The Filling nozzles can be shut off, anti drops the filling valve can be single direction for thin liquid and butterfly valve for viscous products the top tank is for optional, and can be with mixing and heating function if need.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Peristaltic pump liquid filling machine is one type of liquid filler which adapts the positive displacement pump as a dosing system.The pumps use the principle of peristalsis as the basis for their design. It is mostly application for filling small dosing liquid, for it is high GMP standard,and only the inner bore of the tube touches the fluid, it eliminate the risk of the pump contaminating the fluid, or the fluid contaminating the pump, so most of the phamarcy factories adapt this equipment for filling their liquid into small vial, such as eye drops, ear drops,phamarceuticals liquids, also some top cosmetics ,biology liquid also filling by the peristaltic pump. Feature Easy to install, simple to operate and inexpensive to maintain For different flavor liquids only change the tubes high filling accuracy for small dosing liquid, from 1ml to 100ml is the best filling range if consider both the filling accuracy and speed Servo motor driven, easy adjustable filling volume.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Some key features of the IBC weighing filling machine may include: High-precision load cells Automatic tare and gross weighing functions Product-specific filling programs Easy-to-use touchscreen interfaces Automatic valve control for precise filling Automatic IBC positioning and clamping A range of safety features, such as emergency stop buttons and safety guarding Overall, the IBC weighing filling machine is an excellent investment for any business that requires accurate and efficient filling processes for intermediate bulk containers.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Net weight filling machines use a weigh scale platform to monitor the weight of product as it is filling into a bottle or container. Net weight fillers are well suited for large container filling applications. This type machine is used for 5kg -30 kg,and 50KG to 300KG, and IBC system liquid filling. both of gravity filling or pump feeding liquid system with weight scale under filling nozzle or under the conveyor to assure filling accuracy. It can finish a series of operations automatically, such as bottle inlet, weight filling, and bottle outlet. Especially for SL, edible oil lubrication. it is a nice choice for foodstuff, pharmacy, cosmetic and chemical industries.Linear type machine, can be made with 2/4/6/8 filling nozzle for different filling capacity.

Request for a quoteManufacturer/ Producer

No.2009 Xupan road, Jiading disctrict

201808 Shanghai - China