- europages

- >

- Magnets

- >

- STRONG MAGNETS GMBH

- >

- products

STRONG MAGNETS GMBH

Germany

Manufacturer/ Producer

STRONG MAGNETS GMBH

Germany

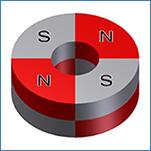

The corrosion resistance of Neodymium magnet is considered poor, surface coating is highly recommended for Neodymium magnets. With the expansion of elevators, wind turbines and permanent motors application, the users need higher requirement on corrosion resistance of Neodymium magnet, as the glue cohesiveness of unplated magnet is much better than plated magnets, also unplated products are better in the security. Now, more and more customers tend to use unplated magnets, upon this condition we have developed ultralow weight loss magnets after the continuous innovation and study. Normally, the weight loss test is over 150mg/cm² in the industry of Neodymium magnet, this will be different for magnets produced from different material formulation and manufacturing process. A lot of our new magnets can reach to 1mg/cm², (Testing condition HAST standard for 168hrs), due to its very low weight loss, the corrosion resistance is excellent

Request for a quote

STRONG MAGNETS GMBH

Germany

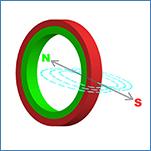

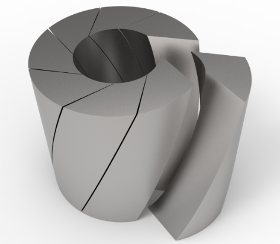

Neodymium magnet (aka NdFeB magnet), is the third generation of rare earth magnet, which is composed of Neodymium, Iron, Boron and a few transition metals. With high remanence, high coercive force, high energy product, and high performance /cost, Neodymium magnet is currently the strongest magnet available in the world. Manufacturing Process Neodymium, Iron, Boron and a few transition metals will be mixed into the Neodymium powder, then fine Neodymium powder will be compacted in a die and sintered, fusing the powder in a solid state. There are two ways of pressing die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances. Machining & Tolerance Generally, Neodymium magnet must be machined using diamondgrinding techniques. Sometimes, machining operations may be performed on Neodymium materials with carbide tools, but surface finishes thus obtained may be less than optimal.

Request for a quote

STRONG MAGNETS GMBH

Germany

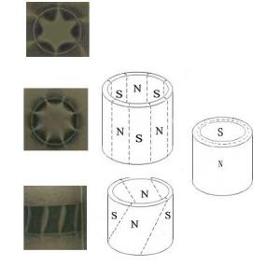

The injected Neodymium magnets are magnetic products mixed with different plastic products. Its main advantage is the diversity of molding offered by the injection process, allowing the products to be customized to meet the needs of the customers. Advantage Injected Neodymium magnets are more resistant to corrosion than sintered Neodymium magnets, with this character, they can be used in most applications without special coatings.Produced by injection process, injected magnets are with high precision and are tailored for each application. This type of injected magnets can be used under working temperature from 100oC to 200oC with good performance. Application The scope of application of the injected magnets is very wide, our magnets are widely in different industrial sectors, such as automotive, electronics, robotics ...

Request for a quoteManufacturer/ Producer

Goldberger str. 92

40822 Mettmann - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

HOMESHOP

Poland

The Hinovo powerbank is a useful gadget with MagSafe or Qi wireless charging. The product achieves wireless charging with a maximum power of 15W. This allows any compatible device to be charged effectively. The powerbank can be charged via the USB-C port, which supports power up to 20W, which gives us about 3 hours of charging from 0% to 100%. The housing is made of non-slip ABS, which increases safety and prevents it from slipping out of your hand. In addition, protection against overheating of the device and a cooling system have been built in. The gadget is small in size and ideal for taking it with you on a trip to a backpack or handbag.

Request for a quote

HOMESHOP

Poland

The Hinovo powerbank is a useful gadget with MagSafe or Qi wireless charging. The product achieves wireless charging with a maximum power of 15W. This allows any compatible device to be charged effectively. The powerbank can be charged via the USB-C port, which supports power up to 20W, which gives us about 3 hours of charging from 0% to 100%. The housing is made of non-slip ABS, which increases safety and prevents it from slipping out of your hand. In addition, protection against overheating of the device and a cooling system have been built in. The gadget is small in size and ideal for taking it with you on a trip to a backpack or handbag.

Request for a quote

PARSMEGA MAKINA

Turkey

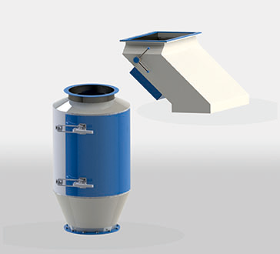

It is one of the auxiliary equipment that prevents metal and metallic parts from damaging the system by attracting them. Most of the machines working in Flour and Feed Factories rotate at high speeds. Screws and similar metal and metallic parts that break off during operation in the natural environment where the product comes from and in other machines enter our working machines and systems and cause damage. The magnet helps catch these pieces before they enter our machines and systems.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

The characteristics of Samarium Cobalt Magnet •Very high magnetic properties with good stability •Superior resistance to high temperature, Curie temperature of majority is over 800°C •Excellent corrosion resistance capability, no coating is needed for surface protection

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free