VILLINA LLC - Manufacturer of pumps for the oil, gas and chemical industries

Russia

Manufacturer/ Producer

VILLINA LLC

Russia

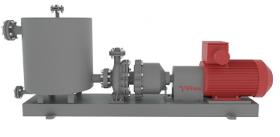

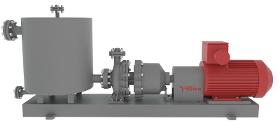

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. Advantages: the fluid can be taken in at a point lower than the axis of the inlet suction pipe without using a pre-installed vacuum pump. - Purpose: transit of corrosive, toxic, explosive and flammable fluids at insufficient suction pressure; - Pump rate ranges: 0.8 to 450 m3/h; - Head ranges: 3 to 132 m; - Self-priming height (depth): up to 6 metres; - Seal type: magnetic coupling according to API 685 or tandem mechanical seal according to API 682; - Climatic version: for moderate and for moderate and cold climate; - Temperature of the pumped fluid: for GNGC-S, GNGC-S-M up to plus 350°С, for NCG-S up to plus 450°С; - Shaft speed: 1,450 or 2,900 rpm; - Structural design: ОН-2 single-stage back pull-out pump according to API 610 or a single block.

Request for a quote

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. However, operation of centrifugal pumps requires building positive pressure (pressure boosting) upstream of the inlet suction pipe for the following reasons: to fill the pump body with the pumped fluid in order to avoid a "dry start" to prevent cavitation during pump operation. Classic methods for creating pressure boosting before centrifugal pumps can be: installation of a tank from which the fluid is pumped, several meters above the axis of the pump shaft and placing the pump in the draw-off sump; inclusion of an additional vacuum pump into the process, which is capable of building the desired pressure boosting of several metres. HOW IS THE PROBLEM OF CREATING A PRESSURE BOOSTING IN MODERN SELF-PRIMING CENTRIFUGAL PUMPS SOLVED? Villina company offers you Villina self-priming GNGC series

Request for a quote

VILLINA LLC

Russia

Modern petrochemical and gas industries typically use horizontal centrifugal canned pump units with magnetic couplings similar to Villina-GNGC type pumps. They are designed for transiting neutral, corrosive, toxic, as well as explosive and flammable liquids in stationary conditions, the vapors of which can form explosive mixtures with air. Magnetic coupling pumps combine complete tightness, smooth operation, long service life and high maintainability. A sub-type of horizontal pumping units are high-temperature pumps Temperature of the pumped fluid: -50°C to +420°C; viscosity up to 26 cSt; density 2,000 kg/m3 maximum; mass concentration of solid non-abrasive inclusions up to 0.2%; size 0.2 mm maximum Permanent magnets (SmCo) with an operating temperature of up to 450°C are used for operation in these temperature conditions. The pump, a part of the pumping unit, is a single-stage or multi-stage horizontal centrifugal section-type

Request for a quote

VILLINA LLC

Russia

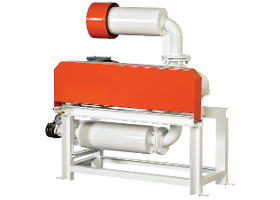

Villina-VS1-M type pumps are designed for use in oil and gas and chemical industries for transit of explosive and highly flammable liquids as well as corrosive media and natural gas liquids. A distinctive feature of these pumps is the ability to transit contaminated liquids with particle size of 3 to 12 mm (depending on the pump rate). MAIN SPECIFICATIONS - Pump rate ranges: 2 to 108 m3/h; - Head: 11 to 178.5 m; - Temperature of the pumped fluid: -50°С to +440°С.

Request for a quoteVillina LLC is a manufacturer of pumps for the oil, gas and chemical industries: horizontal and vertical pumps, semi-submersible pumps, and with spare parts for them. The product range includes: • pump units with magnetic coupling; • pumps with mechanical shaft seal and combined seal; • vertical, horizontal, semi-submersible, combination pumps; • high-temperature pumps with magnetic coupling for pumping media with temperature up to +420°C; • replacement parts for pumps. Villina manufactures both standard type and customized pump units. The equipment complies with TR CU 012, GOST 32601-2013, API 610 and API 685 standards. The company was established in 2011. Villina pumps are used in oil refining, gas industry, chemical industry, and food industry. The equipment is employed in Russia’s Far North region on icebreakers, on an ice-frozen platform for helicopter refueling installed at the North Pole. The manufacturer's high-temperature pump also handles the pumping of vegetable oil with a temperature of +250°C at the oil factory. Villina's centrifugal pumps are employed by Kamchatka's Gold of Kamchatka company. This mining project has been recognized as the best in Russia. Villina's industrial pumps are used by companies in Russia, Azerbaijan, Kazakhstan, Uzbekistan, and Belarus. The manufacturer readily offers delivery of pumps from the standard range and addressing customer's specific challenges through the efforts of its own engineering and design team.

Website

Documents

Company info

Key figures

-

- Company headcount

- 11 – 50

-

- Sales staff

- 1 – 10

-

- % of export sales

- 2%

Organisation

-

- Year established

- 2011

-

- pages.epage-home.site-status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Payment methods

- Swift transfer

Banks

- Sberbank

- VTB Bank

Delivery areas

Terms of delivery (incoterms)

- Purchaser

- Shared

- Vendor

Activities of VILLINA LLC

- Pumps

- Pumps, hydraulic

- Centrifugal pumps

- vertical pumps

- highly heat-resistant pumps

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

POMPES JAPY

France

Body, flange, screw and shaft: stainless steel Couplings: stainless steel (nylon as an option with code -A) Membrane and valves: made of a hydrocarbon-resistant elastomer (Neoprene as an option with code -A) Lever: zinc-plated steel with a rubber handle, 1 metre in length

Request for a quote

PARSMEGA MAKINA

Turkey

Blower pumps are used in mill systems to meet the air required by the supersonic filter and to transport products vertically and horizontally.

Request for a quote

FOCQUET

Belgium

"We have different solutions at the industrial pump level. We offer two solutions in our product range: thermal oil transfer or water transfer. In the pumps offered by Focquet, we have mainly bare shaft pumps mounted on base, monobloc pumps and in-line pumps. The pump department is specialized in the overhaul of pumps of all brands and the assembly of pump units with a very short delivery time. We have a great deal of expertise and know-how in industrial pumps and a large stock of spare parts in order to respond to our customers' emergencies as well as possible."

Request for a quote

FOCQUET

Belgium

"We have different solutions at the industrial pump level. We offer two solutions in our product range: thermal oil transfer or water transfer. In the pumps offered by Focquet, we have mainly bare shaft pumps mounted on base, monobloc pumps and in-line pumps. The pump department is specialized in the overhaul of pumps of all brands and the assembly of pump units with a very short delivery time. We have a great deal of expertise and know-how in industrial pumps and a large stock of spare parts in order to respond to our customers' emergencies as well as possible."

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free