- europages

- >

- Bearings- ball

- >

- WIB SA

- >

- products

WIB SA - Precision Redefined for a World in Motion

Switzerland

Manufacturer/ Producer

WIB SA

Switzerland

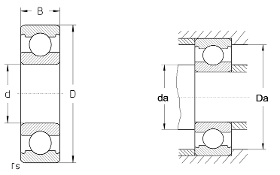

Although single row radial bearings are designed primarily to support a radial load, they perform relatively well under thrust or combined radial and thrust load with the added advantage of low noise, vibration, and drag torque. The internal architecture and cage selection can be designed to meet the specific needs of the application, from high speed to high load. Thin section deep groove ball bearings have a small radial cross-sectional thickness that are used when compactness is required. We manufacture deep groove ball bearings with a minimum bore diameter of 3 mm to a maximum outer diameter of 47 mm.

Request for a quote

WIB SA

Switzerland

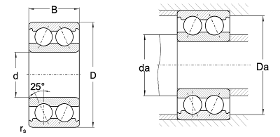

Double-row angular contact ball bearings are used in applications when heavy radial, thrust or combined loads demand axial rigidity of the shaft are required. This is similar to a duplex pair of single- row bearings due to its two rows of balls and angular-contact construction, which provide greater axial and radial rigidity than can be obtained by using a single-row radial bearing. We manufacture these ball bearings with a minimum bore diameter of 3 mm to a maximum outer diameter of 47 mm.

Request for a quote

WIB SA

Switzerland

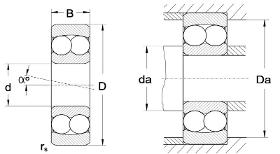

Self-aligning ball bearings have two rows of balls, a common sphered raceway in the outer ring and two deep uninterrupted raceway grooves in the inner ring. This type of ball bearing is recommended when alignment of the shaft and housing is difficult, and the shaft may flex. Unlike a single row or double row ball bearing, the self-aligning bearing’s performance will not be affected by misalignment. Therefore, they are particularly suitable for application where misalignment can arise from errors in mounting or shaft deflection inherent in the application. These bearings are made with seal or without seal.

Request for a quote

WIB SA

Switzerland

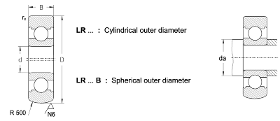

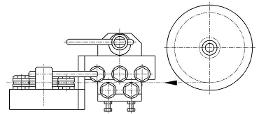

Track rollers—also referred to as idler rollers—are motion transmission components designed to work with all varieties of tracks. They are used in conveyor systems, cam drives, and a wide range of similar material handling systems. Regardless of the material or machine, these components play a critical role in track and rail operations. When selected, employed, and maintained properly, they facilitate system operations, allowing for greater speed and efficiency. Single row track rollers are available with spherical outer ring running surfaces or cylindrical (or flat) outer ring running surfaces. View our page of Special Profiles found under Technical Parameters for some of the more common profiles on the running surface.

Request for a quote

WIB SA

Switzerland

These track rollers offer the same features of a single row track roller with the added benefit of heavy radial, thrust or combined loads. Yoke-type track rollers are single or double-row units mounted on shafts or studs. Similar to the single row track roller, we can customize the running surface to meet the specific requirements of the applications. Cam rollers are similar in their construction to single and double-row support rollers, except that the raceway is formed by a heavy-section roller stud with a fixing thread. The most common running surface profiles can be found on the Special Profiles page under Technical Parameters.

Request for a quote

WIB SA

Switzerland

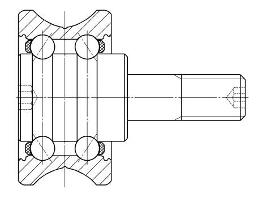

The manufacturing precision of the roller has a major influence on the quality of the final product (wires) as well as on the service life of the rollers. It is therefore essential that the ground “V” groove on the outer ring is machined and positioned precisely relative to the internal geometry. WIB only produces straightener roller bearings produced in this fashion, while many other producers machine the outer wire guide groove after assembly

Request for a quote

WIB SA

Switzerland

As the leading manufacturer of linear guide system bearings, WIB works collaboratively with customers on the development of common and tailor designs, supplying the best-in-class technical and commercial solution for each unique application. Each parameter, including environmental factors, precision requirements, speed, temperature, load, boundary dimensions are thoroughly evaluated during the design and development phase.

Request for a quote

WIB SA

Switzerland

Only bearings specifically developed for each application will cope optimally with the required specifications. With our wide experience in the field of working with such challenges, WIB is uniquely positioned to offer the most appropriate solutions. We have developed application specific solutions through extensive R&D efforts carried out in collaboration with our customers. It is through such joint effort that the quality of the final product has been improved to constantly meet evolving market demands.

Request for a quote

WIB SA

Switzerland

You’re developing advanced technologies that keep your business and your industry moving. When it’s time to move beyond standard bearing to custom ball bearings solutions designed for uniquely challenging applications, WIB is a world-class partner.

Request for a quote

WIB SA

Switzerland

When your needs go beyond simple miniature ball bearings to complete sub-assemblies, the professionals at WIB can help. Drawing on decades of experience in designing systems using a wide range of materials, we have the expertise to produce a sub-assembly that delivers optimum precision, performance, and life. During the process, we make sure our solutions fit perfectly into your production system.

Request for a quoteManufacturer/ Producer

Rue de Champ-Barby 61

1630 Bulle - Switzerland