WIGTEC FISCHEREDER KG

Germany

Manufacturer/ Producer

WIGTEC FISCHEREDER KG

Germany

In the WTH 200.2, the following materials can be reliably brazed with active materials in a high vacuum. PCD (polycrystalline diamond) MKD (monocrystalline diamond) CVD diamond (chemical vapour deposition) PCBN (cubic boron nitride) and Hard metals as well Ceramics In the high-vacuum furnace WTH 200.2, our customers manufacture indexable inserts, dressing wheels, rotating tools and turning tools with blades made of natural diamond or MKD for polish turning. The vacuum brazing is flux-free. In the so-called active brazing process, titanium allows wetting of the surfaces. While cemented hard metals can also be inductively brazed, diamonds, CVD and ceramics must be actively brazed in a vacuum. When brazing PCD and PCBN, not only the hard metal substrate but also the PCD or PCBN layers are wetted.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

The vacuum technology is divided into the areas of measurement, generation and maintenance of a vacuum and the resulting technical applications. Vacuum technology is used in various fields of research and industry, for example in the handling and treatment of materials, in food and medical technology. Benefit from our many years of expertise in the conception and implementation of innovative and high-quality solutions in the field of vacuum technology components and plants.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

The use of components in processing equipment, production facilities or transport containers in food technology is subject to the regulations for so-called food contact materials. For example, the use of food contact materials in compliance with EU legislation must ensure that the composition, taste and odour of the food is not compromised.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

The requirements placed on components in the medical sector are extremely stringent, since, for example, the welds, in addition to the technical quality, must also meet the highest demands in terms of optics. For example, we produce stainless steel slideways for the slip rings of computer tomographs. We were also able to support our customers here in choosing the materials and the definition of the welded joint.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

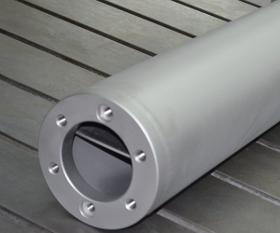

In the field of standard components, we are also your competent contact. Primarily, we manufacture the following standard components: KF flanges CF flanges Aseptic flanges In all common DN sizes, as well as customized components, for example, in terms of length or shape. Of course, we can also offer you blind flanges and more in this regard

Request for a quote

WIGTEC FISCHEREDER KG

Germany

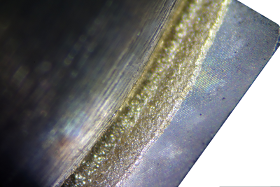

Tungsten inert gas (TIG) welding offers many advantages over other fusion welding methods, such as the complete absence of spatter and low welding-fume emissions. Since TIG welding uses a non-consumable electrode, the process is ideal for welding so-called root passes or in forced positions due to the decoupling of current and welding consumables.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

The idea of the protective effect of argon was continued in our specially designed autoclave. In contrast to Wig – hand welding, there is 100% protection of the seam and root side. This leads to a weld seam not chemically affected by ambient gases.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

Machining is a generic term for various manufacturing processes such as milling or turning used to give workpieces a specific shape by removing excess material via mechanical influences. According to the wishes of our customers, we can realise high surface qualities with sealing surfaces as well as a dimensional accuracy of 10 μm. Machining can be used on a variety of different materials: Stainless steel Non-ferrous metals Nickel-based materials Titanium materials Plastics

Request for a quote

WIGTEC FISCHEREDER KG

Germany

Traverse path: 1250 x 1250 x 870 A axle ± 140° C – axle 360° (endless) High precision machining centre in gantry construction All axles are double-equipped with motor and linear scales Rotary axles are driven by torque motors Zero point clamping system

Request for a quote