XUFENG TOOL TECH GROUP LIMITED - Expert for Customized Metal and Plastic Parts

China

Manufacturer/ Producer

XUFENG TOOL TECH GROUP LIMITED

China

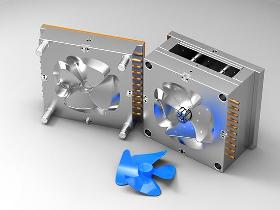

XF has 15 injection Machines on a 7 day shift system, our constant shift pattern enable us to confidently offer reduced lead times and faster deliveries to you. we export many molds each year to North America,Europe,etc mainly for small to medium molds, automotive partis,electrical parts, etc Rich molding experience in processing various materials including ABS, PP, PS, PC ,PMMA, PE,POM, PA6/66+GF,PET, PBT, TPE. 100-850 tones machine capacity Our technique staffs will do periodical checking and maintenance to ensure our machine run normally and all of our products have passed through very strict quality control before shipment.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Materials: stainless steel, carbon steel, alloy steel, aluminum, zinc alloy, copper, brass,POM, PC, PA, Teflon, PVC and ABS Process: raw material, rough machining, finish machining Surface treatment: plating, spraying, anodizing, electro polishing and coating Tolerance: ±0.01mm OEM/ODM orders are welcome Customized designs are welcome Standards: DIN, JIS, ASTM, AISI, BS and GB Packaging: precision machining parts Inner: PE bag or customized Outer: wooden case or carton or customized Size: customized

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

1.Part material: stainless steel 2.Machining type: precision cnc turning 3.Surface:Polishing ,Ra0.8 4.Tolerance:+/-0.02mm 5.Application : Machine parts 6.Quality,reliability and long product life.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Material:Stainless steel, copper alloy,aluminum alloy and so on Surface treatment:Polishing, Zinc plating, Nickel plating, Chrome plating, powder coating, Anodizing, E-coating Drawing operation:PDF, JPG, Auto CAD, Pro/Engineer, Solid Works, UG. Etc. Industry:Automotive, Electrical, Building, Furniture,Mechanical, Machine assembly, Computer, Air industry. Electronics etc. Professional team :Over 10 years experience in metal fabrication Delivery time:Strictly according to customer confirmed order. Package detail:Standard export package or as customers' specific requirement

Request for a quoteXUFENG TOOL TECH GROUP LIMITED

China

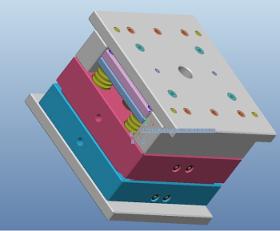

Rapid tooling Service We offer rapid tooling service, when parts demand quantity is hundreds to thousands,you will need to consdie this service and when your demand items are similar structure, types are many and demand quanity is not big then quick Turn Tooling. Rapid tooling for plastics and Die Casting of metal (Aluminum alloy or Zinc Alloy). Also we has stable surface treatment partner with different finishing like sand blasting, texture, painting, powder coating and so on, depending on our customers' requirements. We can make tool life to be 5k to 100ks or more. So if you have such project coming, you are welcomed to inquiry us freely . What Is Rapid tooling Rapid tooling is starting to be used to create molds for commercial operations,to simplify the mould structure for low cost & short lead-time. Rapid tooling provides a way to quickly provide molds to moulding the required products for low volume production demand. apid tooling material usually are Al7075 and...

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

1.Part material: brass 2.Machining type: precision cnc cutting 3.Surface:Polishing ,Ra0.8 4.Tolerance:+/-0.05mm 5.Application : Machine parts 6.Quality,reliability and long product life.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Rapid tooling for plastics and Die Casting of metal (Aluminum alloy or Zinc Alloy). Also we has stable surface treatment partner with different finishing like sand blasting, texture, painting, powder coating and so on, depending on our customers' requirements. We can make tool life to be 5k to 100ks or more. So if you have such project coming, you are welcomed to inquiry us freely . We manufacture our rapid toolings in material aluminium, P20, NAK80 and S136 tool steel, which can be run in a standard injection moulding machine to produce production quality parts in low-volumes. P20 prototype tooling for volumes up to 50,000+ shots. NAK80 or S136 prototype tooling for volumes up to 100,000+ shots. Prototype tooling in 5 to 28 calendar days. Tooling Lead-Time get short leadtime, Low Cost - reduced Cost from material ,MFG , Allowing real trials ,Allows functional test of parts on initial design stage, Many design faults are debugged before mass big production.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Low-Volume Manufacturing Service Low-volume production services help you reduce tooling costs and refine designs. Throughout the process, Our technical staff can assist you in finding the right low volume production approach,and cost effective solution for your manufacturing needs. Usually the quantity ranging from a few hundred up to thousands. We offer various production technologies , helping to bridge the gap between prototyping and full-scale production. Generally speaking, we work with you every step of the way, from initial project review and quotation to production to inspection and delivery. pls inquiry us today if you comes such demand Manufacturing in low volumes is an ideal solution for managing your inventory and testing the market before producing larger quantities. We can make 100,000+ parts fast either one time or on a regular basis.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes. Countless everyday objects are fabricated from sheet metal. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate steel or "structural steel.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Plastic Injection Molding Service Xufeng specilized in fabricating plastic injection moulding parts and mould tools over 10 years ,98% are for export. Here we are expert on rapid injection molding ,We offer toolings design and building at our workshop and we are used to working on low and medium volume production Runs. part material molding range widely like ABS,PP,PC,PMMA,PET,PA6/PA66,PA66+GF... Our Advantages Of Plastic Injection Molding Rich molding experience in processing various materials including ABS, PP, PS, PC ,PMMA, PE,POM, PA6/66+GF,PET, PBT, TPE. 100-850 tones machine capacity Our technique staffs will do periodical checking and maintenance to ensure our machine run normally and all of our products have passed through very strict quality control before shipment. Small quantity trial order are welcome ,we all pay attention to our job. Injection moulding parts cover auto parts ,electrical& electronic parts...

Request for a quoteManufacturer/ Producer

Building # 3 ,HongJing Industrial park,

Dongda Street, ShaTou, ChangAn, GuangDong

523861 Dongguan - China

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free