YONGMING MACHINERY MANUFACTURING CO., LTD - Supplier of grain cleaning, seed shelling and toasting, residue processing, and relevant supporting

China

Manufacturer/ Producer

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Vibration Impurity Separator is mainly used for sunflower seed & kernel, pumpkin seed & kernel and other finished materials processing in end of production line, which can remove broken materials generated in the upstream processing efficiently, and process final product kernel with higher complete kernel rate with higher product value. The equipment is composed of two layers of screen, with fish scale screen and double vibration motor to achieve the best separation effect. At the same time, the machine is equipped with a cyclone dust removal for impurities cleaning effect in some extent. The product has simple structure and excellent sorting effect, and it is an important part of seed and kernel product processing line.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The equipment is widely used in different bulk foods detection, like nuts, seed kernel, peanut, beans, dehydrated fruits and vegetables, tea, Chinese herbal medicine and others. It can identify and remove metal, glass, stone, soil, etc. Especially for nuts, the X ray machine also can remove wormhole grains, empty seeds, shriveled grains, etc. The material into the device and distribute uniformly on the conveyor belt through the vibration feeder, The ray of X-ray generator penetrate materials, then distinguish and extraction according to by image, foreign body discharge to waste tube through the injection valve, finished products turn out from another port.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

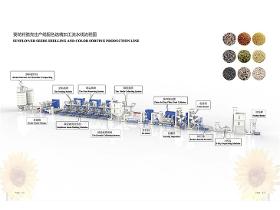

With view of the increasing market demand for sunflower kernel oil, basing on 20-year patented dehulling equipments’ manufacturing advantage,the large capacity sunflower seed dehulling equipment for oil pressing purpose KTF5-3000 is our self-developed equipment to meet the needs of large capacity with premium quality of sunflower kernel oil production. Fully Equipped Seed Processing Production Line Plant . It involves a great deal of preparation to have a beautifully decorated design. We start with measuring the workshop area to get its length, width and height, then according to the entrance or exit of workshop, we are to plan the starter in the processing line. That includes how the materials are to be fed, pit making or feeding platform, and storage tank for materials reserving or processing directly. We need to consider how many materials would you be processing? And what is the degree of quality that you need

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Sunflower Seeds Shelling Production Line is a convenient processing line with high efficiency and less labor designed by our company for customers with large capacity requirements. It is a combined production line led by KTF5-3000 sunflower seeds shelling machine. The line is designed to confectionery sunflower seeds and remove the husk from the sunflower seeds before pressing the oil. The line processes oil sunflower, from which oil is then pressed. Description of the Line for Sunflower Dehulling (oil pressing): Intake and Cleaning: Sunflower is cleaned from larger and smaller impurities on Grain Impurity Screen Cleaner with an aspiration pre-cleaner. After cleaning, the sunflower is sorted. The Grain Grade Cleaner machine gains a dimensional spectrum of seeds suitable for dehulling. This is followed by destoning on a 125 MODEL DE-STONER.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

It involves a great deal of preparation to have a beautifully decorated design. We start with measuring the workshop area to get its length, width and height, then according to the entrance or exit of workshop, we are to plan the starter in the processing line. That includes how the materials are to be fed, pit making or feeding platform, and storage tank for materials reserving or processing directly. We need to consider how many materials would you be processing? And what is the degree of quality that you need? Where is the proper place for storage finished products? Where is the good exit for finished products transportation by truck? When all these information are gathered then we will be contributing to processing equipment.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

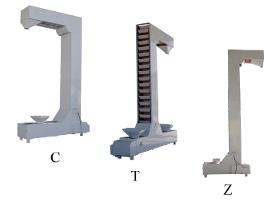

The Non broken Elevator is used in the production line for convenient and cost effective transportation of materials. This elevator model as the name suggests comes with zero broken rate thanks to the transportation driven by chains. This occurs at a slower speed as to prevent any contact between materials and the system. This product is applicable to hoisting a wide range of materials like sunflower seeds, kernels, grains, foods, herbal materials and other easily breakable materials. This product is used for both horizontal and vertical conveying of materials, and is compatible to work in the production line as a single unit or multiple units combined in to one that is suitable for more feeding or discharging. The height of lifting and length of horizontal delivery is customizable, and the structure can be built by steel - carbon or stainless.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

One of the most efficient ways to elevate bulk materials vertically is a bucket elevator. This bucket elevator is suited for transportation of cereals, seeds, fertilizers of granular products. A bucket elevator consists of a series of buckets attached to a belt with sprockets located at the top and bottom of the unit. Bulk materials are loaded into each bucket as the bucket moves past an inlet point. As the bucket goes over the head sprocket, materials pour out of the bucket into a discharge. It is worth noting that our bucket elevator is greatly flexible as it meets the construction requirements of individual plant layouts, i.e. height, bucket width, and carbon or stainless steel build. With weather-proof & dust-proof construction and security measures that are carefully fitted to maintain product integrity and work environment. Thus, that is the reliable bucket elevator of maximum grain throughput and less grain damage base on stable operation in processing production.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The belt conveyor is the more economical method of transporting bulk materials over short and long distances. This is ideal for conveying bulk materials of large lump size, such as crops,fruit, wood,sand,etc.It has a wide belt that slides over a metal bed for smooth,quiet conveying of items placed on the belt from point A to B.The layout of your plant can be simplified and made more efficient with the use of belt conveyors.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The screw conveyor is system designed to transportation of loose bulk product from one place to another,alternatively used for waste treatment(shells,peels)loading and unloading the transportation vehicles or silos. The product moves up forward by means of spiral wings in the pipe; When the product reaches to the exit point, products discharged down from the spiral eject point.Using multiple discharge points,screw conveyors efficiently distribute bulk materials to different areas.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The device is an automatic quantifying, weighing and packaging device. The material is put into weighing box of machine from inlet, when the weight reaches preset amount, the inlet is closed. After the control system receives the signal that bag is prepared, the material is discharged from outlet into the bag. When all the material enters the bag, the control system opens pneumatic valve, transports the bag by the conveyor and brings it to the sewing machine for sewing. This machine can pack 450-500 bags of materials per hour, and it reduce the labor cost effectively and packing accuracy control. PRODUCT FEATURES ·High efficiency. It adopts three-speed feeding mode with fast, medium and fast speed; ·High accuracy with high-precision control instrument, auto-error correction, auto-overfault alarm, and parameter settings backup in power failure; ·Wide range of weighing, customized bag-sewing machine with auto package sewing and auto-shearing, innovative optical fiber sensing technology.

Request for a quoteManufacturer/ Producer

Langshan Town,Linhe District

015000 Bayannaoer - China