ZETEK SP. Z O.O. - CMM services, design and production of press tools

Poland

Manufacturer/ Producer

ZETEK SP. Z O.O.

Poland

Transfer tools play an important role in the serial production of parts. They allow for the automation of often simple activities, thanks to which it is possible to shorten the production time of the finished product. They also involve the employee's participation to a minimum. Transfer tools work in sequence, with the created elements being moved one by one between stations using special grips. Contrary to progressive tools , the part is cut from the strip in the first station and then shaped in the next stages of the process. In order to achieve optimal work results, it is necessary to perfectly synchronize all activities. This requires not only an appropriate design, but also a simulation. Thanks to many years of experience and appropriate technological facilities, we produce Line / Transfer Die Stamping tools that meet all your expectations. Our technological facilities consist

Request for a quote

ZETEK SP. Z O.O.

Poland

Progressive tools are widely used in many areas of production. They enable the production of many details of the same shape or dimensions in a short time. That is why they are perfect for serial production of machine construction elements, household appliances or utility items. At the same time, they are also used in the production of single prototype elements. Among the many types of tools in this category are progressive dies and dies . The latter can be found, among others, in the automotive industry, where about 95% of elements are formed by forming on presses. Progressive dies, like other tools we supply, are used for plastic working of thin metals. They are multi-measure tools. They perform a specific element in a few movements (tacts), with a different feature assigned to each successive pressure of the die. Dies and other progressive tools consist of a die and a punch. Designed with the use of modern programs such as CAD, they can have very complex shapes.

Request for a quote

ZETEK SP. Z O.O.

Poland

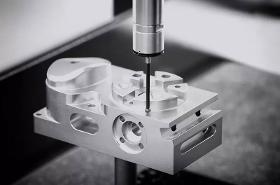

Cutting elements from material sheets is a basic activity in the serial production of details. The accuracy of their performance depends on the accuracy of subsequent activities, such as e.g. 3D forming or punching. They all contribute to the quality of the effect, and thus also of the finished product. Cutting and progressive dies play an extremely important role in this process . These are tools installed in hydraulic works, which are responsible for making an element of a specific shape and dimensions from a sheet of thin sheet metal. The trimmer should be designed and made with very high precision. It depends on what the effects of his work will be, i.e. the accuracy of mapping the manufactured details. In designing such tools, we use specialized CAD software. On the other hand, precise CNC machining on numerically controlled machines guarantees an extremely accurate representation of the project. Thanks to these possibilities, we offer customers the execution of even very complex

Request for a quote

ZETEK SP. Z O.O.

Poland

Serial production of details for the construction of cars, machines or household appliances is associated with the need to maintain a high level of dimensional precision. Especially in the case of machines and components in motion, their parts must be perfectly matched so that they interact without causing friction and accelerating the rate of wear. That is why systematic CMM measurements performed with the use of special coordinate measuring machines are so important. These machines are equipped with three measuring systems enabling simultaneous measurements in the XYZ coordinate axes. An additional element is a probe that allows you to locate the surface of the measured element. CMM coordinate measurementsthey take place automatically and are made with the use of CNC technology, also commonly used in precise CNC machining . Such production tests are characterized by very high accuracy and are not exposed to errors resulting from human physical limitations or his subjective approach

Request for a quote

ZETEK SP. Z O.O.

Poland

Precise CNC machining is currently the basis for the implementation of many production processes. Thanks to it, it is possible to manufacture details that are very complex in shape, such as gears, bearing elements, drive shafts, specialized tools or screws with non-standard parameters. It is used both in serial production and where prototypes are created and individual elements must be made based on technical drawings. It is also irreplaceable in the production of progressive tools . Precise CNC machining with the use of numerically controlled CNC machines also guarantees a very high repeatability of the elements made. At the same time, it reduces the time of their production and contributes to the economic use of materials, and as a result - to lower production costs. Such effects are determined both by the preservation of the set parameters throughout the production period of the series and the elimination of human errors. Precise CNC machining is also one

Request for a quote

ZETEK SP. Z O.O.

Poland

The production of parts for machines and devices, the work of which requires very high precision and matching of each element, must undergo strict quality control. One of its elements is the dimensional compliance test, so important, for example, in the case of elements of bearings, gears or motors. Therefore, control and measurement instruments are an important part of the equipment of every company that carries out such serial production . These include, among others, coordinate machines with which CMM coordinate measurements are made . The precision of these machines' operation creates much greater possibilities than those offered by traditional control instruments - calipers, length gauges, micrometers, etc. The offer of the ZETEK company includes modern control and measuring instruments such as a coordinate measuring machine or a portable measuring arm. Thanks to its mobility, it allows you to take measurements anywhere, outside the laboratory or production hall

Request for a quote

ZETEK SP. Z O.O.

Poland

GLOBAL EVO is one of the newest CMMs, which is characterized by high precision and accuracy. It is intended for measurements of details, in which the complexity of shapes makes manual control devices such as micrometers, altimeters, calipers impossible. It also replaces those gauges whose specifications contain very narrow tolerance fields. Measurement with an accuracy of 0.004 mm allows you to maintain stringent quality standards recognized by the largest automotive concerns in the world. CMM machines from the GLOBAL series also have large dimensions of the work table, thanks to which we can measure parts of larger dimensions. It should also be mentioned the increased efficiency thanks to which the measuring time can be reduced by up to 20% compared to other CMMs.

Request for a quote

ZETEK SP. Z O.O.

Poland

Control and measurement devices can also be used outside the production site or research laboratory. The Absolute Arm Compact measuring arm is designed for such purposes and combines ultra-high accuracy with a compact size. The device was designed for optimal measurement results in hard-to-reach places. Simply put, the Absolute Arm Compact is still the most accurate measuring arm in the world, while offering an accuracy in the range of 6 microns. Consolidating advanced portable arm technology into an extremely portable package, this arm is the ideal solution for making absolutely accurate measurements of small and medium-sized parts.

Request for a quote

ZETEK SP. Z O.O.

Poland

The production of complex shaped elements formed from sheet metal requires the use of very precise tools. Designing them with the use of specialized programs such as CAD and supplementing with the visualization of the finished stamp is not always sufficient to guarantee a satisfactory effect. Therefore, a stamping simulation is essential to make sure it is correct before introducing progressive dies or cutting tools into production . Authors and PAM STAMP is the software we use to perform such a simulation. Both programs are a perfect solution for companies wishing to design and launch a new product. PAM STAMP stamping process simulation enables initial part feasibility assessment, tool design and full verification simulation. We can predict how the material will behave during each pressing phase. This solution makes it possible to optimize the process so that the pressed detail does not show any tendency to cracking, folding or excessive springback.

Request for a quote