- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- blade sharpening

Results for

Blade sharpening - Import export

BIZERBA SE & CO. KG

Germany

The VS12 W stands out due to its wealth of variants. Individual and powerful slicer for a variety of products to be sliced in manual mode. The vertical carriage ensures ergonomic, upright operation while providing an optimal view of the slicing result. The core component is a powerful blade drive, optionally with intelligent motor control Emotion®. In addition, the VS12 W can be fitted with Ceraclean® surface which is easy to clean and ensures easy feeding of products to the blade. Workflows for target weight slicing of up to 3 kg / 2 g are more efficient and precise due to a fully integrated portion scale.

Request for a quote

WESTMARK GMBH

Germany

• very solid design • specially sharpened blade • comfort-soft-touch handle

Request for a quote

HAN SONG M&T

South Korea

·Copper, Graphite and non-ferrous metal ·Special coating to maximize the wear-resistance

Request for a quote

FEMIA INDUSTRIE

France

Cuts husked ears of corn. Capacity of 60 ears/minute (according to the performance of the operator who is feeding the cutter). Machine primarily comprised of a cutting head with 6 blades arranged like a diaphragm of a camera. Self clearing of the cutter head in case of jams. The cutter requires the very specific WKS blade sharpener.

Request for a quote

FEMIA INDUSTRIE

France

Cuts husked ears of corn. Capacity of 110 ears/minute. Machine primarily comprised of a feeder belt and a rotating bowl that allows for transfer of cobs on a corn belt one after the other and correctly aligned, of an automatic “head first” orientation system of the ears and of a cutting head comprised of 6 blades arranged like a diaphragm of a camera. The orientation system is also capable of “diverting” ears that are too short. Self clearing of the cutter head is case of jams. The cutter requires the dedicated WKS blade sharpener.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Sharpener KSG processes the blades gently with short setup times thanks to its intelligent sharpening technology. The sharpening unit is positioned via a visor. Sharpener KSG guarantees rapid, reproducible sharpening and has a long service life thanks to the sharpening disks which are not actively driven. A counter is integrated for individual specification of sharpening cycles. Advantages Long service life thanks to non-actively driven sharpening discs Sharpening unit positioning via sighting tool Gentle processing due to clever sharpening technology Quick, reproducible sharpening Counter for the individual specification of sharpening cycles Short set-up times Simple operation Clear, robust technology

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Get the most out of your slicer blades! With the weSHARP 7000 sharpening center, you can quickly and easily get back the ideal slicing properties of your blades, even after intensive use in the slicer. The weSHARP 7000 is suitable for the refurbishment of all Weber Durablade Performance, involute and circular blades, and guarantees a precise and reproducible sharpening result with minimal material loss of the cutting edge. Thanks to program recognition and data storage, the sharpening process can be completed in the shortest possible time, and the use of tool-free fast-change systems also ensures that setup times are kept to a minimum. Advantages Simple operation with RFID technology Sharpening of all Durablade circular and involute blades Precise and reproducible sharpening result Precise sharpening process thanks to servo drive Convenient handling via touchscreen

Request for a quote

MEGAPROJECTS BV

Netherlands

These knife sharpeners contain two options for sharpening knives: rollers with zirconium dioxide coating for fine-tuning the blade to polish it for a softer and smoother cut and tungsten carbide coated rollers for rough sharpening of the blade, which helps to repair the damaged blade, including smoothing chips and bumps on its surface.

Request for a quote

MEGAPROJECTS BV

Netherlands

These knife sharpeners contain two options for sharpening knives: rollers with zirconium dioxide coating for fine-tuning the blade to polish it for a softer and smoother cut and tungsten carbide coated rollers for rough sharpening of the blade, which helps to repair the damaged blade, including smoothing chips and bumps on its surface.

Request for a quote

WESTMARK GMBH

Germany

• the original with chrome-plated handle • with screwed on blade • with sharpened corer for damaged spots

Request for a quote

WESTMARK GMBH

Germany

• the sturdy original from aluminium • coring of the fruit and 10 even segments in one action • specially sharpened blade assembly • the matching plate-like base ensures that the fruit is completely cut

Request for a quotePOUGET

France

USE : Holes to countersink the Heads of Coachscrews into Long Wooden Sleepers. ADVANTAGES : Simples, Tough, Adjustable and easy to Re-sharpen. - Steel Body - Superior High-Speed steel blade locked with a conical Key - Range of Adjustment : Ø 38 to Ø 80 mm Hole. - Centering Attachment Ø 15 mm - Total Length = 230 mm - Net Weight = 1 Kg - 23 mm Square Shank Drive - Ref. FR-23 - Ø 16 mm Cylindrical Shank Drive - Ref. FR-16 OPTIONS : - H.S.S Spare Blade ( can be re-sharpened) - Ref. LFR

Request for a quote

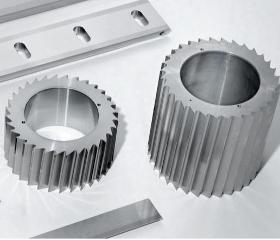

KENNEDY GRINDING LTD

United Kingdom

Kennedy Grinding provides a high quality regrinding service for all types of straight and rotary machine knives. We ensure all knives are straightened and checked for flatness during the grinding process. All customer’s knives are recorded, detailing geometry and wear rate, enabling us to give advance warning when knives are approaching the end of their useful life. We also offer a comprehensive collection and delivery service throughout England, Scotland and Wales. In addition, our technical department is on hand to assist with any problems that may occur. When you are looking for consistency and quality, our reputation and technical expertise assures you of superior regrinds every time. • Rotary Slitters • Crush Cut Knives • Multi-Knife Blocks • Knife Holders

Request for a quote

KENNEDY GRINDING LTD

United Kingdom

Kennedy Grinding provides a high quality regrinding service for all types of straight and rotary machine knives. We ensure all knives are straightened and checked for flatness during the grinding process. All customer’s knives are recorded, detailing geometry and wear rate, enabling us to give advance warning when knives are approaching the end of their useful life. We also offer a comprehensive collection and delivery service throughout England, Scotland and Wales. In addition, our technical department is on hand to assist with any problems that may occur. When you are looking for consistency and quality, our reputation and technical expertise assures you of superior regrinds every time. • Steel and TCT Paper Knives • 3- and 6-Knife Trimmer Sets • Paper Drills • Bookbinding Knives • Perforator Knives • Knife Management Programs • Packaging Knives and Cutters

Request for a quote

FERNITE OF SHEFFIELD LIMITED

United Kingdom

A blunt blade “pushes” paper instead of slicing it, resulting in poor quality edges, tearing and shredding paper when cutting. To achieve faultless quality of cut paper it is important to regularly check and sharpen the blades of mechanical paper cutting guillotines.

Request for a quote

KENNEDY GRINDING LTD

United Kingdom

• TCT Circular Saw Blades • Wide and Narrow Bandsaws • Chipper Blades • TCT & PCD Tooling • Planer Blades and Irons • Chisels, Chains, Cutters, Drill & Router Blades

Request for a quote

KENNEDY GRINDING LTD

United Kingdom

Kennedy Grinding provides a high quality regrinding service for all types of straight and rotary machine knives. We ensure all knives are straightened and checked for flatness during the grinding process. All customer’s knives are recorded, detailing geometry and wear rate, enabling us to give advance warning when knives are approaching the end of their useful life. We also offer a comprehensive collection and delivery service throughout England, Scotland and Wales. In addition, our technical department is on hand to assist with any problems that may occur. When you are looking for consistency and quality, our reputation and technical expertise assures you of superior regrinds every time. • Granulator Knives • Shredding Knives • Baler Blades • Pelletiser Knives • Compound Knives

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KENNEDY GRINDING LTD

United Kingdom

Kennedy Grinding provides a high quality regrinding service for all types of straight and rotary machine knives. We ensure all knives are straightened and checked for flatness during the grinding process. All customer’s knives are recorded, detailing geometry and wear rate, enabling us to give advance warning when knives are approaching the end of their useful life. We also offer a comprehensive collection and delivery service throughout England, Scotland and Wales. In addition, our technical department is on hand to assist with any problems that may occur. When you are looking for consistency and quality, our reputation and technical expertise assures you of superior regrinds every time.• Rotary Shear Knives • Shear Blades • Rubber Stripper Rings • Shimless Tool Systems • Press Brake Tooling • 5 Axis Grinding

Request for a quote

FERNITE OF SHEFFIELD LIMITED

United Kingdom

Our granulator knife sharpening service is provided from Fernite’s ISO 9001 certified factory in Sheffield. Our professional and experienced knife sharpening experts look after your knives as they would if they were sharpening a brand new knife. We recommend sending your granulator knives to us as a complete set, so we ensure that the knives tolerances required by the granulator manufacturer are maintained. Please let us know what type of material you are processing, as thinner materials often require tighter blade tolerances. We have the capacity to sharpen blades of up to 6 metres. We are using less rigid porous grinding abrasives for minimal-loading and cool surface sharpening. Therefore, your knife doesn’t produce overheat and doesn’t become more brittle as a result. Correct equipment for sharpening either Carbon, Alloy, or even Tungsten Tipped granulator knife. On custom request, a Granulator Knife can be finish ground to profile.

Request for a quote

FERNITE OF SHEFFIELD LIMITED

United Kingdom

As granulators, shredders and pelletizers are among the most commonly used blades, we offer a wide variety of common and specially designed knives for them. The life of a granulator blade life is a tough one. That’s why at Fernite, we use only quality steel from European accredited mills,manufacturing every blade with absolute precision. We manufacture to OEM specifications across a wide range of brands. We’ve a large catalogue of blade drawings, but we’re equally happy to create drawings from your samples, which we do free of charge. We’ll even sharpen your blades whilst we have them, so that you can keep your production going (charges apply).

Request for a quoteResults for

Blade sharpening - Import exportNumber of results

21 ProductsCompany type

Category