- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- built-in tools

Results for

Built-in tools - Import export

ERO PROJEKT D.O.O.

Slovenia

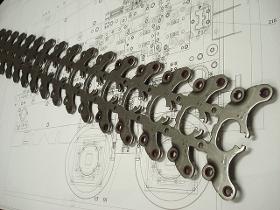

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Digital Torque & Angle Wrench Sturtevant Richmont has long been known for torque wrenches that can stand up to the rigors of the industrial world. Part of that legendary durability comes from size. The DTC is our newest digital torque and angle wrench. This is a great audit or assembly tool, with built-in innovation. We've taken the transducer from the Exacta 2 Series wrench and placed in the body of our CCM wrench. It is now half the weight of an Exacta Series wrench and the slimmer profile gives you access to points that may have been difficult to reach with an Exacta. We packed in some great features like torque and angle modes of operation. The result is a tool is like no other. Agile. Slim. Lightweight. The DTC has a b/w display and colored light bands on the side of the wrench. Those bands change yellow to green when the target values are achieved. An auditory beep and the handle vibrates provide two additional modes of operator focused error proofing guidance.

Request for a quote

SFS GROUP GERMANY GMBH - GESIPA

Germany

It's small, it's fast, it's nimble! And that's not all. The new Birdie® from GESIPA is the smallest and lightest battery-powered blind riveting tool in its performance class. Plus it has an ergonomic design with a balanced centre of gravity and a non-slip, handy handle. Fatigue-free working comes built in! What’s more, the riveting tool covers a wide range of applications: with a setting force of 10,000 N and a tool stroke of 25 mm, the Birdie® makes light work of setting blind rivets with a diameter of up to 5 mm in all materials. And, like the Bird Pro series, the Birdie® works with the tried-and-tested cross-manufacturer batteries from CAS.

Request for a quote

EMO - ORODJARNA D.O.O.

Slovenia

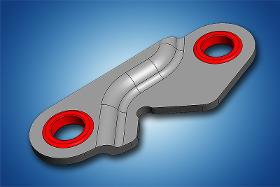

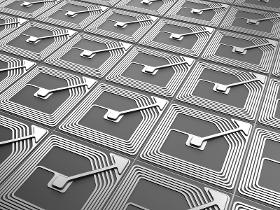

Smart tools have built-in chips, sensors and detectors to identify important maintenance data. Sensor-equipped tools allow the buyer to measure and control various parameters such as: - Wear control of cutting blades - Forming forces - Cutting forces - The resultant of forces on the press - Number of pieces - Move and waste control - Control of key dimensions of the end product - Pressure control - Control of the injection of screws, nuts and other elements Tool chipping In order to achieve higher cost effectiveness of maintenance, we equip replaceable tool parts with RFID chips. The data that the buyer reads with the RFID reader is transmitted from the server of EMO Orodjarna. In this way, the buyer can read with the RFID reader all the necessary information required to produce or order a new position at EMO Orodjarna. Virtualization of tools Enhanced reality and virtualization technology enables greater reliability and repeatability of the work process for the buyer.

Request for a quote

NOVOSIM

Turkey

Custom Software Development Process Monitoring and Automation solutions are designed to streamline the software development lifecycle by automating key processes and providing real-time monitoring capabilities. These solutions help software development teams manage projects more efficiently, reduce errors, and improve overall productivity. The system automates various stages of the software development process, including requirements gathering, code generation, testing, and deployment. It offers customizable workflows and task management features to ensure smooth project execution and collaboration among team members. With built-in monitoring and reporting tools, the solution provides insights into project progress, resource utilization, and performance metrics. It enables stakeholders to make informed decisions and optimize development processes for better outcomes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LVD

Belgium

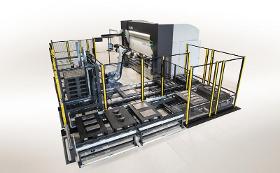

Ulti-Form takes automated bending a step forward with a ToolCell-inspired automated tool changing press brake using a built-in tooling warehouse and equipped with Easy-Form® Laser adaptive bending technology. Programming for both the press brake and robot is handled offline with no robot teaching needed. An auto-adaptive robot gripper designed by LVD automatically adjusts to the workpiece size, allowing different part geometries to be processed without a gripper change. KEY FEATURES Automated tool changer press brake reduces setup time Easy-Form® Laser adaptive bending technology ensures part accuracy KUKA robot and press brake work in synergy to minimize changeover time Programming is handled completely offline, no robot teaching Auto-adapting, universal gripper handles part sizes from 50 x 100 mm up to 1200 x 800 mm High productivity in a compact space, including three input pallets and output zone for up to 10 pallets Automated pallet dispenser and conveyor

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The Hunger RDS is designed to precision machine the seat ring bores in cylinder heads to produce smooth and closely fitting contact surfaces for oversize seat inserts. Features The RDS is equipped for counterboring as well as for facing the bottom of seat ring bores in a lathe-type action with a single point carbide cutter. The RDS is aligned in centerline with the valve guide by means of a pilot which is locked in the valve guide. An universal steady stabilizes the RDS against lateral displacement. Pilots and steady furnished with Hunger valve seat refacing tool also suit for the corresponding RDS tool. The built in feed gear mechanism for automatic longitudinal and cross feed of the single point cutter eliminates the need for multiple cutter sets and other accessories. An adjustable stop for the tool slide permits quick selection of the proper sized bore diameter.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Advantages - Very short refacing time - Easy to use - Modular add-on components - Powered by low operating voltage Features The machine is fitted with two motors providing a smooth cutting action. The operating voltage supplied to the motors by a compact power supply unit is of the low voltage type to eliminate electric hazards. The exchangeable adapter head with the built-in slideway for cutting tool travel ensures a precise seat angle eliminating faulty setting operations. Roundness, concentricity and surface finish of the refaced valve seat are within manufacturers’ specifications or even better. Handling Setup is fast and easy. First, lock the pilot with mounted centering spider in the valve guide. Then, lower the machine over the pilot and position the cutting tool in front of the inner edge of the valve seat. Turn micrometer downfeed to set the desired depth of cut. Refacing is automatic. Pressing one button is enough to start the refacing pass.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Advantages - Very short refacing time! - No dust! - No noise! - Powered by low operating voltage! Features The machine is fitted with two motors providing a smooth cutting action. The operating voltage supplied to the motors by a compact power supply unit is of the low voltage type to eliminate electric hazards. The exchangeable adapter head with the built-in slideway for cutting tool travel ensures a precise seat angle eliminating faulty setting operations. Roundness, concentricity and surface finish of the refaced valve seat are within manufacturers’ specifications or even better. Handling Setup is fast and easy. First, lock the pilot with mounted centering spider in the valve guide. Then, lower the machine over the pilot and position the cutting tool in front of the inner edge of the valve seat. Turn micrometer downfeed to set the desired depth of cut. Refacing is automatic. Pressing one button is enough to start the refacing pass.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Advantages - Very short refacing time! - No dust! - No noise! - Powered by low operating voltage! Features: The machine is fitted with two motors providing a smooth cutting action. The operating voltage supplied to the motors by a compact power supply unit is of the low voltage type to eliminate electric hazards. The exchangeable adapter head with the built-in slideway for cutting tool travel ensures a precise seat angle eliminating faulty setting operations. Roundness, concentricity and surface finish of the refaced valve seat are within manufacturers’ specifications or even better. Handling Setup is fast and easy. First, lock the pilot with mounted centering spider in the valve guide. Then, lower the machine over the pilot and position the cutting tool in front of the inner edge of the valve seat. Turn micrometer downfeed to set the desired depth of cut. Refacing is automatic. Pressing one button is enough to start the refacing pass.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

Inductor design and manufacture continues to be one of eldec’s core competences. The inductor forms the foundation of every eldec induction machine. Every inductor is specifically made-to-order for a workpiece. The basis of this is the frequency, material and power density which means that precisely that area of the workpiece is heated that should be heated. eldec heating cables are used for the heating of large components. The form of the inductor and its design are tailored to the geometry of the workpiece area it is to heat. An inductor from eldec is designed using the very latest 3-D CAD solid modelling software, manufactured on CNC machine tools and built by trained personnel with excellent training at eldec in Germany and the USA. This means that every inductor is made to measure, precise and highly accurate.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

Inductor design and manufacture continues to be one of eldec’s core competences. The inductor forms the foundation of every eldec induction machine. Every inductor is specifically made-to-order for a workpiece. The basis of this is the frequency, material and power density which means that precisely that area of the workpiece is heated that should be heated. eldec heating cables are used for the heating of large components. The form of the inductor and its design are tailored to the geometry of the workpiece area it is to heat. An inductor from eldec is designed using the very latest 3-D CAD solid modelling software, manufactured on CNC machine tools and built by trained personnel with excellent training at eldec in Germany and the USA. This means that every inductor is made to measure, precise and highly accurate.

Request for a quote

DEMIROREN LABEL

Turkey

Demiroren Labels manufacturer a range of anodized aluminium label suitable for many applications. Since 90s, for special aluminium label on their products, machines and equipments companies around the world have relied on Demirören Label Company. Manufactured from stainless steel, aluminium, coated alloys or brass, your metal name plate is an outstanding way to provide the highest level of durability. Custom metal nameplates are the perfect and permanent solution to show important company information, product ID, operating instructions and safety warnings. Thanks to the precision of the metal nameplates of the Demirören Label, a wide range of global companies rely on us for custom metal dials, scales and stencils. Expertly built to meet precise specifications, these tools are vital to the manufacturing processes of these companies.

Request for a quoteResults for

Built-in tools - Import exportNumber of results

26 ProductsCountries

Company type

Category

- Sheet metals - stamping (13)

- Turning - steels and metals (3)

- Induction heating systems (2)

- Brakes, servo-brakes and accessories (1)

- Customer relations management software CRM (1)

- Hand tools, non-power (1)

- Laser printing (1)

- Magnets (1)

- Metalworking - portable power tools (1)

- Paint mixers and grinding machines (1)