- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- case-hardened steels

Results for

Case-hardened steels - Import export

HFP BANDSTAHL GMBH & CO KG

Germany

This material group comprises C-steel with low carbon content, good formability and fineblanking quality. Due to case hardening, the components have low-wear surface layers with high hardness and sufficient toughness in the core. They thus combine numerous properties and application possibilities in a wide variety of industries. To increase the wear resistance, you can also carburize or carbonitrate partial areas. C 10 E, C 15 E /➔ according to DIN EN 10132 - 2 Depending on the customer's requirements, we supply treatment states from soft annealed to high cold solidified.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

Case Hardening Steels & Steels for Quenching and Tempering EN 10083-2 Unalloyed Steel (C 35/C40/C45/C60, C22E – C60 E+U, +N) EN 10083-3 Alloyed Steel (25CrMo4, 34CrMo4, 42CrMo4, 51CrV4, 20MnB5, 30MnB5…) EN 10084 Case Hardening Steel (16MnCr5, 20MnCr5…)

Request for a quote

KANAT CELIK

Turkey

DIN: 21NICRMO2 - 16MNCR5 - 20MNCR5 SAE: 8620 - 5115 - 5120

Request for a quote

A J MARSHALL (SPECIAL STEELS) LTD

United Kingdom

Stocked steel grades: 12/14% Manganese, X120 Mn12, X120 Mn13, Creusabro M, ASTM A128 Grade B2, DIN W1.3401. A high manganese, fully austenitic, quench annealed, non-magnetic, work hardening steel with an exceptionally high level of wear resistance when subjected to work hardening by shock or high impact pressure in service. The underlayers not work-hardened maintain an excellent resistance to shock and a very high ductility. TYPICAL APPLICATIONS: Earth moving crusher jaw, grizzly, screen, stone chutes, chain guide, shredder plates, shovel buckets, bucket blade of loader, chain conveyor parts, sprocket wheel, various armouring elements. Guiding and shifting plates, scraps container, liner of shot blasting unit, wear liner, shot blasting equipment. All steel is supplied with full mill test certificates to DIN EN 10204-3.1. Payment: L/C, T/T, Cheque, Transfer, Cash, VISA.

KEBA FASTENINGS

Germany

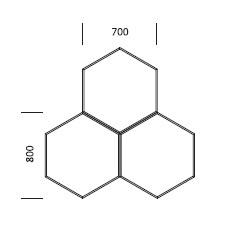

are bolts hot forged from all common materials including stainless, acid resistant and heatproof (inductive hardening, case hardening, quenched and tempered) steel. Diameter range of M 12 - M 80 with lengths reaching up to 800 mm. Tailored manufacturing according to specific standards, drawings and samples.

Request for a quote

NORELEM FRANCE

France

Ball element case-hardened steel. Thrust pad ETG 100 steel.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

We supply both from stocks and productions wide range of round bars , certified acc to. EN 10204 2.2 and/or 3.1 Steels for General Use of EN 10025 (S235/275/355 JR/J0/J2) Steels for Quenching and Tempering acc. EN 10083-2, EN 10083-3 Steels for Case Hardening acc. EN 10084 (C10, C15, 16MnCr5, 20MnCr5, 36CrMn5 (UNI7845) Micro-alloyed Steels (18MnV5, 20MnV6) Free Cutting Steels acc. EN 10087(11SMn30/11SMn37) Other Grades upon request. Structural Steel Carbons Steel Case Hardening Steel Heat Treated Steel Spring Steel Free Cutting Steel Tool Steel Stainless Steel

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

PT screws for thermoplastics: Thread rolling screws for direct screwing into plastics, Thread 30° or 60° KTG screws for thermoplastics: Single-start or double-start thread (high, low) Thread rolling screws are extruded for larger batch sizes and turned for small batch sizes (Turned parts for direct screwing) High tensile and highly stressable connection of thermoplastics with considerably longer life endurance Thread rolling without chips and loss of material Minimum radial tension, large thread coverage Process-reliable due to torsion strength Shorter and slimmer screws are possible. Materials: Steel, case-hardened Quenched and tempered steel 1.5523 tempered to 1000 +200 N/mm², high-grade steel 1.4567, other materials on request Length: 3 – 160 mm (at lengths from 60 mm only partial thread lengths 4 x d are possible) Thread diameter: 1.6 – 10 mm Special dimensions on request Batch sizes: Standard ex-stores Special screws from 30,000 pieces

Request for a quote

NLMK-EUROPE-PLATE

Belgium

Produced in Italy by NLMK Verona, which is become an undisputed producer of high quality forged blocks and bars, the ingots are available in a wide range of grades: •Case hardening steel •Heat treatable steel •Creep resistance steel •Martensitic stainless steel •Ball and roller bearing steel •Tool steel •Micro alloy steel •Nitriding steel •Tough at subzero steel •Pressure Vessel steel Applications : Oil & gas, wind power generation, shipbuilding, heavy engineering, nuclear power, automotive, etc. Category Case hardening steel Heat treatable steel Creap resistance steel Martensitic stainless steel Ball and roller bearing steel Tool steel Micro alloy steel Nitriding steel Tought at subzero steel Pressure vessel steel

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

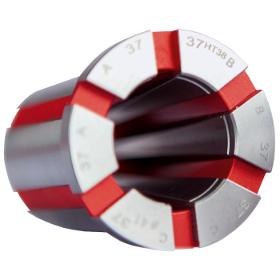

In terms of precision, stability, and flexibility the vulcanized segmented clamping bushings are unbeatable. They consist of segments made of chrome/nickel, case hardened steel that is very hard, extremely wear resistant, and rigid [60 HRC]. Plus, they do not have to »bend« to clamp the workpiece. In addition, all functional surfaces are completely ground in one clamping set-up. The result: maximum run-out accuracy, maximum holding power, and long life span.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Whether lathe or machining center Complete machining made easy: You cannot only use our MANDO and MAXXOS segmented mandrels on the lathe, you can also use them in stationary mode. Simply screw the mandrel onto the ms dock [manually actuated] or hs dock [hydraulically actuated] and you can clamp your workpiece from the inside, stationary mode. Precise, without vibration and with minimum set-up effort. The extremely wear-resistant segmented clamping bushing of case-hardened chromium-nickel-steel with the rubber between the segments, especially developed by HAINBUCH, makes it possible. Hydraulic actuating unit hs dock hs dock is an absolute powerhouse that enables hydraulic implementation of MANDO and MAXXOS segmented mandrels on machining centers. Media supply can be freely selected. It is actuated either from the side or via a base plate from below. Perfect when automation is involved.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Whether lathe or machining center Complete machining made easy: You cannot only use our MANDO and MAXXOS segmented mandrels on the lathe, you can also use them in stationary mode. Simply screw the mandrel onto the ms dock [manually actuated] or hs dock [hydraulically actuated] and you can clamp your workpiece from the inside, stationary mode. Precise, without vibration and with minimum set-up effort. The extremely wear-resistant segmented clamping bushing of case-hardened chromium-nickel-steel with the rubber between the segments, especially developed by HAINBUCH, makes it possible. Manual actuating unit ms dock The hand-actuated ms dock in conjunction with stationary MANDO and MAXXOS segmented mandrels is ideal for machining centers, measuring machines, radial drill presses, parallel and angle plate clamping or for clamping on dividing heads. The version ms dock rotating can be used on turning and grinding machines until RPM 1/min.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Bush conveyor chains are often used for conveying tasksinvolving long transport distances at relatively low speeds. Since only a small minority of chains used in the industry are totally compliant with one specific standard, ELITE conveyor chains are custom-made to a specific customer order and consequently fulfil a large number of special requirements. ELITE highlights: • Pins usually made of heat-treated alloy steel, inductionhardened • Bushes made from seamless precision steel tube, case-hardened • Link plates made of high-strength tempered steel or case-hardened steel alloy • Rollers (where present) made of case-hardened steel, case-hardened

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KANAT CELIK

Turkey

SIZE RANGE: Hot Rolled:14 MM Up To 90 MM Cold Drawn (Calibrated): 14 MM Up To 65 MM AVAILABLE STEEL GRADES: Carbon Steels Structural Steels Heat Treatable Steels Case Hardening Steels Free Cutting Steels

Request for a quote

KANAT CELIK

Turkey

SIZE RANGE: Hot Rolled: 20X5 MM Up To 1600X10 MM Cold Drawn (Calibrated): 20X5 MM Up To 200X20 MM Forged: 200X100 MM Up To 900X400 MM AVAILABLE STEEL GRADES: Carbon Steels Structural Steels Heat Treatable Steels Case Hardening Steels Free Cutting Steels

Request for a quote

KANAT CELIK

Turkey

SIZE RANGE: Hot Rolled: 10X10 Up To 300x300 MM Cold Drawn (Calibrated): 5X5 Up To 80X80 MM Forged: 200X200 Up To 1000x1000 MM AVAILABLE STEEL GRADES: Carbon Steels Structural Steels Heat Treatable Steels Case Hardening Steels Free Cutting Steels

Request for a quote

KANAT CELIK

Turkey

SIZE RANGE: Hot Rolled: 15 MM Up To 330 MM Cold Drawn (Calibrated): 5 MM Up To 90 MM Peeled: 10 MM Up To 370 MM Forged: 180 MM Up To 1100 MM AVAILABLE STEEL GRADES: Carbon Steels Structural Steels Heat Treatable Steels Case Hardening Steels Free Cutting Steels Bearing Steels

Request for a quotePOUGET

France

USE : Tightening Bolts and Coachscrews suitable to Coachscrewing and Fishbolting Machines. ADVANTAGES : High Technical Quality in case-Hardened chromium-Nickel Steel. Sockets for COACHSCREWING and FISHBOLTING Machines (Drive square 23 mm) Attachment For Coachscrews (Square mm) 8-side Sockets For Rectangular Coachscrews Mixed Sockets Ø 23 Hex 38 18 20 23 27 35 39 41 Ø 20 Ø 23 18 x 24 20 x 27 Pin 136 C1 136 C2 136 A 136 A1 136 A2 136 A3 136 A4 141 A 141 137A1 137 A2 136 (1) Ball 136 B1 136 B2 136 B3 136 B4 136 B5 136 B6 136 B7 141 B 141 C 137 B12 137 B13 136 B Attachment For 6-side Nuts and Bolts (on Flats mm) 12-side Sockets for 38 mm Nuts Long Sockets for 45 mm Nuts on Flats 30 32 36 37 38 40 41 42 45 Pin 137 C1 137 C5 137 C3 137 C4 137 C2 137 B 137 B2 137 B1 137 E2 137 C2E 137 E1 (1) Ball 137 B0 137 B5 137 B3 137 B4 137 B6 137 B7 137 B8 137 B9 137 B10 137 B11 137 B14 Sockets for S.1.P. Impact Wrench in Special Nickel-Chrome Vanadium Steel (Drive Square 25.4 mm) Pin Attachment + Rub

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

CBN (cubic boron nitride) is the next hardest material after diamonds. When properly used, tools made from CBN exhibit considerably less wear than other materials. Cutting inserts or even VHM tools can be equipped with CBN. Technical application: Hardened tool steels with hardnesses greater than 55 HRC or high speed steels (HSS) can be machined without problems using CBN. Case hardened steels and chilled cast iron can also be machined with CBN. Non-ferrous metals are totally unsuitable for CBN; diamond tools are needed for these.

Request for a quoteResults for

Case-hardened steels - Import exportNumber of results

25 ProductsCompany type